Precision Hardware Customized Solutions Manufacturer

Author | Shengwo Industry Insights Team

Updated | December 2025

Contents

Understanding what is an air damper is essential for anyone involved in HVAC system design, construction, or facility management. As modern buildings demand better air quality, energy efficiency, and smarter airflow control, air dampers have become crucial components in both commercial and industrial ventilation systems. They help regulate, control, and balance airflow to ensure stable performance and comfortable indoor environments while reducing energy waste and operational costs for long-term system efficiency.

In today’s HVAC market, engineers and buyers expect components that support automation, flexible adjustment, durability, and precise airflow control. As a manufacturer specializing in sheet metal fabrication, CNC parts machining, and custom HVAC components, Shengwo Machinery continues upgrading its technology and production capabilities to meet these evolving global standards in a highly competitive environment.

This comprehensive guide explains what is an air damper, how it works, the different types available, and how to choose the right one for your HVAC project. You will also learn why more global buyers prefer partnering with Shengwo Machinery for professional, reliable, and long-term HVAC component supply.

To answer the question what is an air damper, it is a mechanical device installed inside HVAC ductwork or air handling units to regulate, block, or control airflow. Air dampers can open, close, or modulate to ensure proper air distribution and maintain safe system pressure levels for different building environments and operational requirements.

Air dampers play a key role in balancing airflow volume, preventing backdraft, reducing energy loss, and enhancing the overall performance of heating, cooling, and ventilation systems. Without properly selected dampers, HVAC equipment may experience reduced efficiency, unstable airflow, and uneven temperature distribution across different zones of a building.

Air dampers are essential across industries including commercial buildings, factories, clean rooms, warehouses, data centers, and industrial ventilation systems. Their reliability directly affects air quality, comfort, energy consumption, and long-term system stability for various demanding HVAC environments.

When learning what is an air damper, understanding its working principle is crucial. An air damper functions by rotating its blades or plates to change the cross-sectional area inside the duct, which regulates airflow volume and direction with consistent mechanical stability and smooth movement.

Most dampers use manual, electrical, pneumatic, or automated actuators to perform opening and closing actions. These actuators send precise signals that adjust the blade angle, allowing the system to deliver the required airflow based on temperature, pressure, or environmental conditions set by the HVAC controls.

By modulating airflow, air dampers help maintain balanced air pressure, prevent air leakage, and support advanced HVAC operations such as zoning systems, smoke control, air purification, and intelligent building automation. This makes them indispensable components in modern ventilation technology across multiple applications.

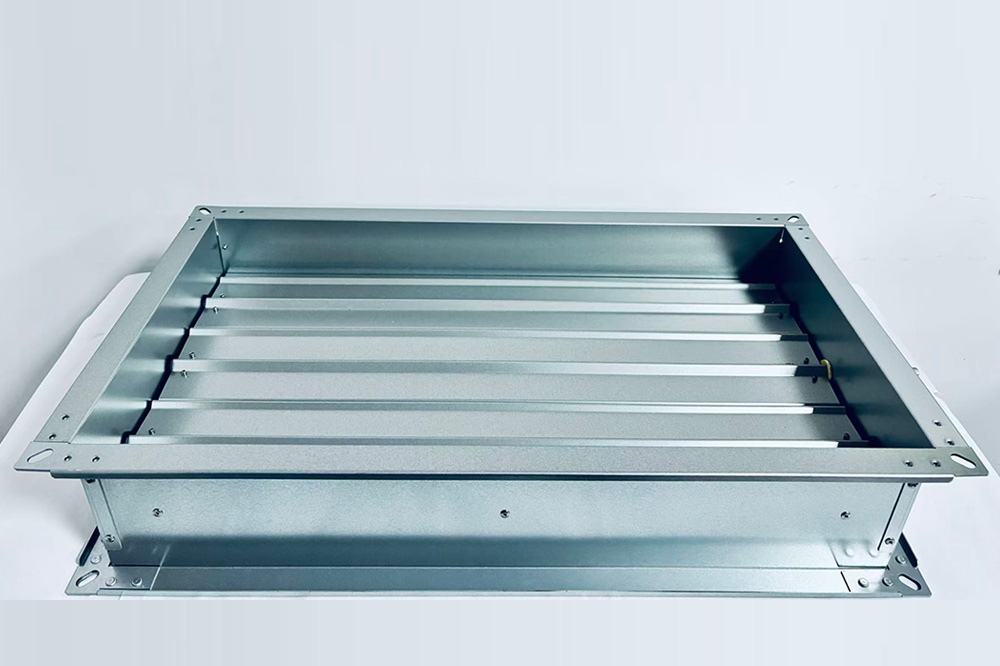

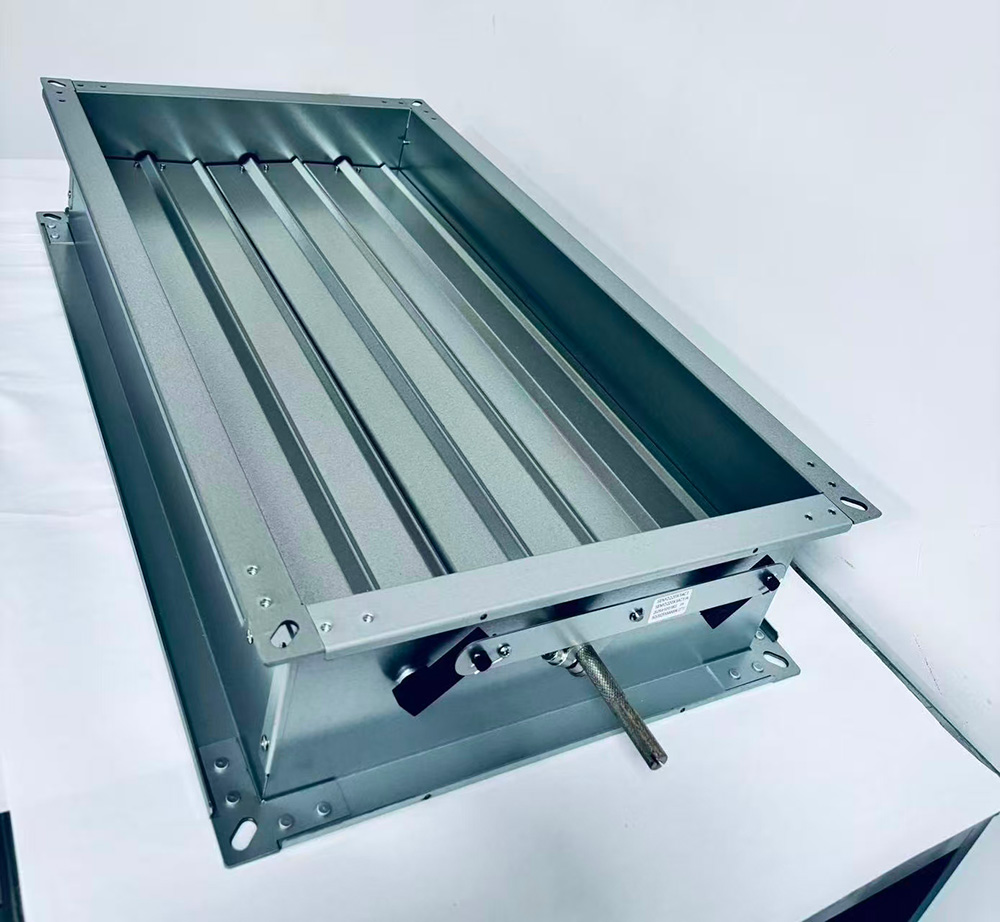

Understanding what is an air damper also requires knowing its main components:

Frame – Provides structure and stability for airflow control.

Blades – Rotate to open or close airflow paths efficiently.

Shafts & Bearings – Ensure smooth and controlled rotation.

Seals & Gaskets – Minimize leakage and improve system efficiency.

Actuator – Controls damper movement manually or automatically.

These parts work together to ensure consistent airflow regulation, reduce vibration, and maintain reliable performance under varying temperature and pressure conditions found in industrial and commercial HVAC systems.

To fully understand what is an air damper, it is important to know the different types available and how each serves specific HVAC requirements. The right damper type ensures optimal airflow management, system safety, and energy efficiency in commercial, residential, and industrial ventilation systems.

Selecting the correct damper improves system reliability, enhances environmental control, and prevents unnecessary energy losses. Each damper type is engineered for particular airflow patterns, temperature levels, and functional demands across various HVAC installations.

Volume Control Dampers are among the most common solutions for managing airflow. When discussing what is an air damper, VCDs represent the standard type used to adjust and balance airflow within duct systems of all sizes.

These dampers modulate airflow by adjusting blade angles to increase or restrict air volume. They are widely used in commercial buildings, factories, and ventilation systems requiring stable and adjustable airflow delivery for everyday operation.

Applications include medium to large HVAC ducts, supply air regulation, and return air balancing. Their versatility and durability make them a preferred choice for engineers handling complex airflow distribution tasks.

Motorized dampers are essential for modern, automated HVAC systems. When someone asks what is an air damper, automated units represent the technologically advanced version capable of integrating with smart building systems.

These dampers operate using electric or pneumatic actuators and respond automatically to system commands. They adjust airflow based on temperature, pressure, or occupancy levels, providing high accuracy and efficient climate control throughout the building.

They are ideal for smart homes, commercial complexes, data centers, and energy-efficient buildings. Their ability to react quickly ensures consistent environment control and reduced human intervention.

Fire dampers are critical safety components installed to prevent the spread of flames through HVAC ducts. Understanding what is an air damper also includes exploring how fire dampers protect buildings during emergencies, ensuring compliance with safety codes.

These dampers automatically close when temperatures reach a certain threshold, sealing off the duct and blocking fire transmission. They are mandatory in fire-rated walls, floors, and partitions for all large commercial and industrial buildings.

Fire dampers significantly improve building safety and protect both people and equipment. Their reliability makes them indispensable components of modern HVAC safety strategies.

Smoke dampers help prevent the spread of smoke during a fire. As part of understanding what is an air damper, these dampers safeguard indoor areas by restricting or redirecting smoke movement inside ventilation ducts.

They remain open during normal operation but close immediately when smoke detection systems are activated. They can also work with fire dampers to enhance building fire protection depending on code requirements.

Smoke dampers are essential for hospitals, offices, shopping centers, and high-occupancy buildings. Their proper function reduces health risks and improves emergency evacuation outcomes.

Backdraft dampers prevent unwanted reverse airflow, ensuring the HVAC system only allows air to move in the intended direction. When learning what is an air damper, these units demonstrate how dampers support system efficiency and indoor comfort.

These dampers open automatically when air flows outward and close when airflow attempts to return. They are used in exhaust systems for kitchens, factories, warehouses, and industrial ventilation where reverse airflow must be prevented.

They help maintain indoor pressure balance, improve energy efficiency, and protect HVAC equipment from external air contamination.

Balancing dampers ensure each branch of the HVAC system receives the correct amount of airflow. As you explore what is an air damper, balancing dampers illustrate how precision control improves overall building performance.

They allow technicians to fine-tune airflow for multi-zone systems and maintain consistent temperatures in different building areas. Their adjustability makes them important during commissioning and long-term HVAC maintenance.

Balancing dampers are widely used in offices, malls, schools, industrial facilities, and any building requiring accurate zone control.

Understanding what is an air damper also means understanding why these components are essential to any HVAC system. Air dampers provide precise airflow management, safety, and system efficiency. When properly selected and installed, they help reduce operational costs and ensure optimal performance for industrial, commercial, and residential environments.

Air dampers allow buildings to maintain stable temperature distribution, improve ventilation quality, and prevent energy waste. Their ability to regulate airflow supports both comfort and safety while extending the lifespan of HVAC equipment.

A key part of understanding what is an air damper is recognizing how it delivers accurate airflow control. By adjusting blade positions, dampers help buildings maintain proper air distribution for heating, cooling, and ventilation.

This precise control enables better comfort, reduces temperature fluctuations, and avoids under-ventilated or over-ventilated areas. In industrial settings, stable airflow ensures that machinery and processes operate safely and efficiently.

Proper airflow control also reduces pressure imbalances, preventing strain on HVAC systems and reducing energy consumption over time.

Energy efficiency is one of the biggest reasons companies want to understand what is an air damper and how it improves HVAC performance. Dampers ensure that conditioned air is delivered only where needed, minimizing energy waste.

By controlling airflow, they reduce unnecessary heating and cooling loads, helping organizations lower utility costs. Automated dampers deliver even greater savings by adjusting airflow in real time based on occupancy and temperature requirements.

This makes dampers critical for green buildings, industrial energy-saving programs, and sustainability-focused engineering designs.

When discussing what is an air damper, temperature regulation is a major benefit. Dampers help maintain consistent temperatures in different zones of a building, improving comfort and reducing strain on HVAC systems.

Multi-zone buildings like offices, hospitals, and malls rely heavily on dampers to prevent hot and cold spots. Proper regulation ensures that all rooms stay within ideal temperature ranges, improving overall user experience.

In industrial facilities, steady temperature control is crucial for product quality, machine performance, and safety.

Anyone researching what is an air damper must understand how these devices contribute to building safety. Fire and smoke dampers help block the spread of flames and smoke during emergencies.

They work as part of a comprehensive fire protection system, activating automatically at high temperatures or when smoke is detected. This helps protect building occupants and maintains the integrity of fire-rated barriers.

By limiting smoke movement, dampers improve evacuation conditions and support faster emergency response.

A well-designed damper system ensures that HVAC equipment operates under stable pressure and airflow conditions. This is an important aspect of what is an air damper and why it matters for long-term efficiency.

Balanced airflow reduces mechanical stress on fans, ducts, and air-handling units. This minimizes the risk of failures, reduces maintenance needs, and extends overall system lifespan.

For manufacturers, warehouses, and commercial operators, reduced downtime translates to better productivity and lower operational costs.

To fully answer what is an air damper, it’s important to understand how it functions inside an HVAC system. Air dampers use adjustable blades or panels to regulate the flow of air through ducts or ventilation openings.

Depending on the damper type, these blades can be controlled manually, automatically, or electronically. Sensors, actuators, and control systems help adjust airflow based on temperature, pressure, or programmed settings to maintain the desired environment.

This simple yet effective mechanism forms the foundation of modern ventilation and climate-control strategies.

Understanding what is an air damper is only the first step—selecting a high-quality damper is equally critical. High-quality dampers ensure long-term stability, precision control, and reliable performance in demanding HVAC environments. Poor-quality dampers may lead to leakage, noise issues, unstable airflow, and higher energy consumption, creating long-term operational problems.

Quality also affects safety. In fire or smoke control systems, a low-quality damper can fail to close properly, putting occupants and property at risk. This is why industrial buyers, contractors, and engineers must carefully evaluate durability, materials, certifications, and manufacturing capabilities.

A reliable air damper helps optimize system costs, reduce maintenance, and increase overall HVAC efficiency for many years.

Building owners and engineers researching what is an air damper should pay attention to material selection. High-quality dampers are usually made from galvanized steel, stainless steel, or aluminum to resist corrosion and deformation.

Durability ensures stable performance even under fluctuating temperatures, humidity, or heavy airflow usage. Strong materials also reduce the risk of blade warping, vibration issues, and premature equipment failure.

For industrial applications, robust material quality prevents airflow leakage and ensures long-term reliability, even in harsh environments.

A major reason to understand what is an air damper is its role in maintaining precise air control. A high-precision damper minimizes leakage, ensuring that airflow follows the intended path without unwanted bypass.

Precision also improves energy efficiency by preventing conditioned air from escaping into unused zones. For large commercial buildings, even a small amount of leakage can significantly impact operational cost over time.

High-precision dampers help maintain optimal pressure balance, improve indoor comfort, and support stable HVAC system performance.

Another important part of what is an air damper involves compliance with industry standards. Certified dampers ensure performance consistency and safety compliance for both domestic and international projects.

Standards measure factors such as:

Fire resistance

Smoke leakage limits

Structural strength

Thermal performance

Durability under repeated cycling

For contractors and engineers, certified products reduce risk and simplify project approvals. For building owners, compliance ensures peace of mind, knowing the ventilation system meets regulatory requirements.

When evaluating what is an air damper, the manufacturer’s experience is a crucial factor. An expert manufacturer understands airflow modeling, material engineering, and HVAC system dynamics more thoroughly.

Experienced manufacturers also offer better customization options, helping clients design dampers that match special industrial needs. They provide precise engineering support, ensuring dampers fit complex duct systems or unique application scenarios.

Choosing an experienced manufacturer also means better after-sales support, faster engineering response, and improved long-term reliability.

After fully understanding what is an air damper, the next step is selecting a supplier who delivers high quality, stable performance, and dependable engineering service. Shengwo Machinery stands out as a trusted manufacturer of air dampers and HVAC components.

With a 2,500 sqm facility expanded by 100%, Shengwo has the production capacity to support both small-batch customization and large-volume supply. As a Schneider Electric SAM-audited green supplier and ISO9001/ISO14001 certified manufacturer, Shengwo meets strict global standards.

Our strength lies in consistent quality, rapid engineering support, and a commitment to safety, delivery, cost, and innovation—five key pillars that drive long-term customer success.

Shengwo Machinery’s delivery capability goes far beyond standard lead times. With ERP digital management and efficient workflow planning, we ensure materials, machining, assembly, and inspection run smoothly with minimal delays.

Shorter lead times help customers accelerate project schedules, while faster communication ensures that design changes, technical issues, or urgent orders are handled promptly. This level of responsiveness is especially important for time-sensitive industrial projects.

Our goal is to offer reliability and speed without compromising quality or accuracy.

Quality is a fundamental part of Shengwo’s manufacturing philosophy. As an ISO9001-certified factory under a UK-accredited certification body, we maintain strict quality control throughout production.

Each damper undergoes dimensional checks, function tests, and airflow inspections to ensure stable performance. Our zero-defect continuous improvement system helps minimize errors and uphold the highest standards.

This commitment to excellence ensures that every product meets the expectations of industrial HVAC engineers and global buyers.

Shengwo delivers strong cost competitiveness without sacrificing performance. By optimizing material usage, upgrading automation, and maintaining a stable supply chain, we offer high-value products at favorable prices.

Customers receive durable, precisely engineered air dampers that perform reliably for years, reducing total cost of ownership. Our cost strategy is built to help clients stay competitive in their markets.

Whether for HVAC integrators, contractors, or equipment manufacturers, Shengwo offers long-term value and dependable pricing.

Q1. What is an air damper in HVAC systems?

An air damper is a device used to regulate or block airflow inside HVAC ductwork, improving efficiency and safety.

Q2. Where are air dampers commonly used?

They are used in commercial buildings, factories, hospitals, warehouses, and ventilation systems.

Q3. What materials are used to manufacture air dampers?

Common materials include stainless steel, galvanized steel, and aluminum alloy.

Q4. Can air dampers be customized?

Yes. Shengwo Machinery provides fully customized air dampers based on size, material, airflow requirements, and control mechanisms.

Q5. Are air dampers necessary for energy efficiency?

Absolutely. Dampers ensure the system operates only where needed, reducing energy waste and improving airflow balance.

Q6. Does Shengwo Machinery offer fast delivery?

Yes. With increased factory capacity and streamlined ERP processes, we ensure quick delivery and excellent communication.

Now that you understand what is an air damper, its importance, and how it supports HVAC performance, choosing the right manufacturer is the next step. Shengwo Machinery provides reliable, customizable, and cost-effective air dampers backed by strong engineering capabilities and international certifications.

Ready to improve your HVAC project with premium air dampers?

Contact Shengwo Machinery today for a fast quote, professional engineering support, and reliable manufacturing service.