10+ Years of Experience

More than 10 years of experience in precision metal fab

Super fast customization

Complete production and delivery within 7 days at the fastest

Quality Assurance

Equipped with a complete ERP system and certified by SGS, ISO 14001, and ISO 9001 for quality management

Rich Craft Support

Provide high-quality materials, professional technology and packaging supporting services to achieve various customized support...

Precision Metal Fab | Custom High-Quality Parts for Kitchen, Electronics & Automotive

SHENGWO specialize in precision metal fab solutions for industries like kitchen equipment, electronics, medical devices, and more. With innovation and quality at our core, we deliver customized components to drive your business forward.

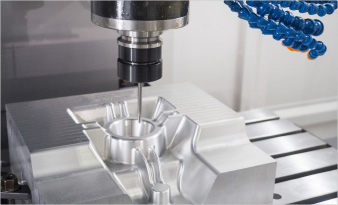

CNC Machining

Using CNC milling and turning, we can custom manufacture a wide range of prototype and production parts

Sheet Metal Fabrication

We have a variety of sheet metal equipment that can achieve high-precision processing of complex-shaped metal parts.

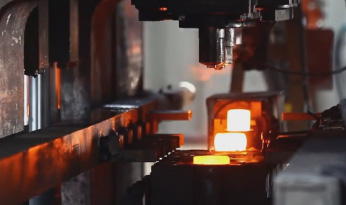

Die Casting

Processing of various complex shapes of metal materials, realizing diversified product production, and quickly completing mass production.

Injection Molding

We have injection mold manufacturing and can provide you with customized injection molded parts and mass production molding.

One-Stop Metal Fabrication Solutions Provider

SHENGWO Machinery takes one-stop service as its core, committed to innovative and efficient solutions, providing the highest quality products and services. It integrates laser cutting, precise bending, and efficient welding, and provides customers with a series of surface treatment support production services such as sheet metal processing, metal stamping, electroplating, and spraying.

Quickly make various precision metal fab parts for you

Parts proofing 1-2 days, large batch delivery 7-14 days.

01

Send Design

Provide key cultural context and project requirements.

02

Quote & Analysis

We conduct design analysis to optimize your parts and provide accurate cost quotations.

03

Production

After the sample and order are confirmed, we will proceed with production as planned and carry out quality inspections.

04

Transportation

Products are securely packaged and shipped on schedule through reliable logistics partners to ensure safe and timely delivery.

About

SHENGWO Machinery | Precision Metal Fab Inc

Zhuhai Shengwo Machinery Technology Co., Ltd. (hereinafter referred to as Shengwo Machinery) is the preferred manufacturing partner for many enterprises, including one of Schneider Electric’s SAM audited green suppliers, a Fortune 500 company.Shengwo has won many honorary certifications such as “National High-tech Enterprise” and “Technology-based Small and Medium Enterprises”, ISO system, and patented technology with its outstanding technical strength and innovation capabilities.Certified to ISO 9001 :2015(Quality Management) and ISO 14001 :2015(Environmental Management) by a UKAS accredited body, recognized by the IAF.

Shengwo Machinery is committed to promoting the development of Industry 4.0 and intelligent manufacturing in China and strives to create a diverse and inclusive corporate culture and work environment. With a 3,000-square-meter production base and office space, Shengwo Machinery has implemented an ERP digital management model reform since 2024, aiming to build a one-stop service factory integrating R&D, reliability testing, structural component production and assembly, finished product assembly and packaging, and logistics capabilities.

Company Vision: To become the world’s most innovative precision sheet metal parts integrated solution manufacturing service provider.

Precision Metal Fab Advantages

Precision Metal Fab Inc

SHENGWO is a professional precision metal fab manufacturer, our engineering and technical department provides strong technical support, allowing us to accept OEM, ODM and customized products. We know that novel and competitive products are the key to making money with customers, so we have been committed to the innovation of technology and process, improving efficiency and quality, and cooperating with our customers to develop competitive products.

Technical support:

Our engineers with more than 10 years of experience will conduct a comprehensive analysis of the parts and provide you with better process structure suggestions to improve product quality, production efficiency and more competitive prices.

Mature supporting support:

Customized hardware parts provide you with one-stop time-saving and worry-free services from material procurement, hardware manufacturing, metal surface treatment, packaging, logistics and transportation. Samples can be delivered in 2 days and batches can be delivered in 7 days.

Quality support

We have a mature ERP production system, strictly implement the ISO9001 quality production system, and have a precision manufacturing rate of up to 95%. We are dedicated to improving the quality assurance for every hardware manufacturing project.

Equipment flexibility

Due to the diversity and variability of metal parts, we focus on functional flexibility in equipment configuration. We have more than 20 equipment such as metal laser cutting, drilling, folding, stamping, welding, painting, electroplating, etc., which can meet the production of small and large batches of metal parts.

Talent specialization

We have introduced various professional talents, including sales personnel, customer service personnel, process analysts, quotation personnel, process engineers, programmers and other technicians. We currently have about 60 employees, of which business elites, technical backbones, production experts and quality model workers account for about 70%.

Production process

In order to ensure production efficiency, quality, delivery date and production cost optimization, all departments, all sections, teams, posts, stations and processes of the company implement process production. Each process has clear operation instructions and standards. For special orders and projects, the project leader is also arranged to follow up the production process.

Quality standardization

Through the comprehensive implementation of ISO quality management system, covering every link from raw material procurement, production process control to finished product testing, the efficient ERP system is combined with lean management to ensure high-quality precision parts.

Quality & Honor

Certifications

SHENGWO has many invention and utility patent certificates. The production strictly implements international quality control standards to ensure product quality. It has passed lSO 9001, lSO 14001, SGS certifications.

Metal hardware manufacturing

Blog

Industrial Electrical Panels & Enclosures | Precision Metal Fabrication Manufacturer

Industrial Electrical Panels and Enclosures for Modern Power Systems Industrial electrical panels and enclosures are fundamental components in modern power distribution, automation, and control systems.

New Year, New Manufacturing Opportunities: Precision Metal Solutions for 2026

New Year, New Manufacturing Opportunities: Precision Metal Solutions for 2026 As the new year begins, businesses around the world are planning for growth, innovation, and

Custom Electrical Enclosures | Precision Metal Processing Solutions

Custom Electrical Enclosures for Industrial Applications Electrical enclosures are essential components in industrial and commercial electrical systems. They provide protection for sensitive equipment and help