Precision Hardware Customized Solutions Manufacturer

Author | Shengwo Industry Insights Team

Updated | November 2025

Contents

Efficient airflow management is the backbone of every HVAC system. Whether in industrial plants, commercial buildings, or data centers, maintaining precise air distribution and pressure control is essential for comfort and performance. A Volume Control Damper (VCD) plays a crucial role in this process by regulating the volume of air that passes through ducts, ensuring optimal ventilation, system balance, and energy efficiency.

In modern HVAC systems, Volume Control Dampers are not just components—they are critical regulators of comfort and cost-efficiency. When properly designed and installed, they help maintain stable internal environments, reduce strain on fans, and support sustainability goals by lowering energy waste.

This article explores what a Volume Control Damper is, how it works, its different types, materials, design features, applications, and the reasons SHENGWO Machinery stands out as a trusted global manufacturer of precision sheet metal and CNC-fabricated HVAC components.

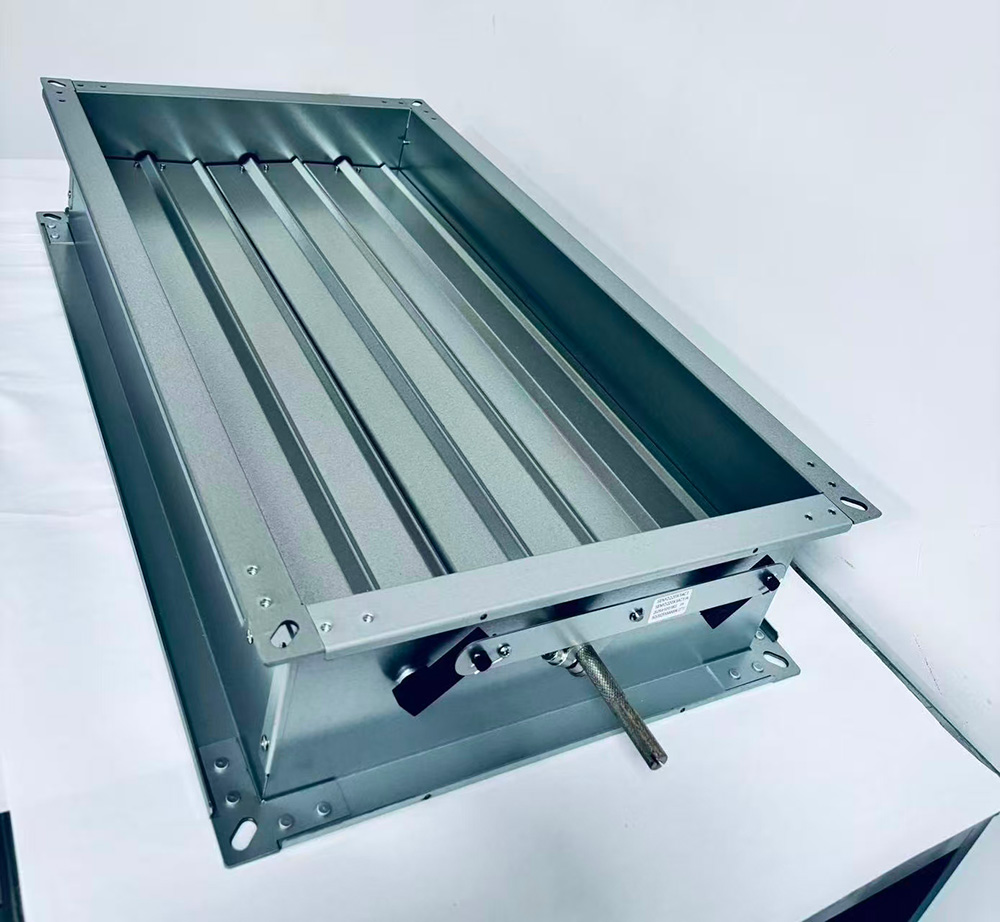

A Volume Control Damper is a mechanical device installed in HVAC duct systems to control, regulate, and balance the airflow within ventilation systems. By adjusting the position of its blades, the damper can increase, reduce, or completely stop the movement of air through specific duct sections.

This functionality is vital for both comfort and performance, allowing operators to precisely control air distribution between rooms, zones, or floors. When multiple dampers work together across a building, they maintain consistent airflow pressure and temperature balance, optimizing the overall system efficiency.

In industrial or commercial environments, Volume Control Dampers also help reduce noise and vibration, improve air quality, and enable maintenance teams to isolate sections without shutting down the entire system—an advantage that greatly enhances operational flexibility.

Maintain balanced air distribution throughout HVAC systems for consistent temperature.

Control air pressure and flow rate in different zones to avoid system imbalance.

Support energy efficiency by minimizing wasted airflow and preventing over-ventilation.

Provide operational flexibility during maintenance or adjustments, improving safety and reliability.

The working principle of a Volume Control Damper is based on airflow resistance and the manipulation of duct cross-section area. When the damper blades rotate, they change how much air can pass through the duct.

At its simplest, when the damper is open, air flows freely with minimal resistance; when it is partially or fully closed, airflow decreases proportionally, allowing precise control over air volume.

Air Entry: Air flows through the duct toward the damper blades. The initial pressure determines how much air the system can deliver to each zone.

Blade Adjustment: A manual lever or an automated actuator changes the blade angle, modifying the effective airflow area.

Flow Regulation: The adjusted angle creates a specific resistance level that regulates airflow according to requirements.

Monitoring and Feedback: Sensors or building automation systems track performance to maintain consistent air distribution and pressure.

In modern smart buildings, motorized Volume Control Dampers are integrated into BMS (Building Management Systems) for automatic feedback control, ensuring dynamic airflow adjustment in real time to achieve comfort and energy savings simultaneously.

Different HVAC environments and performance requirements call for different damper designs. Each type of Volume Control Damper is engineered to balance factors like airflow pattern, speed of response, and control precision.

The manual Volume Control Damper uses a lever or hand wheel for manual adjustment of blade position. It’s cost-effective and best suited for applications where airflow settings rarely change, such as equipment rooms, storage spaces, or static zones.

This damper type is simple to install and requires minimal maintenance, making it ideal for small-scale systems or retrofits. Operators can easily make adjustments during commissioning to achieve balanced airflow without relying on electronic control systems.

A motorized Volume Control Damper uses an electric or pneumatic actuator to control blade movement automatically. This allows remote regulation and integration with digital building management systems (BMS).

It is perfect for modern buildings, hospitals, data centers, or large facilities where real-time airflow monitoring and adjustment are crucial. Motorized dampers not only improve energy management but also enhance comfort by responding immediately to environmental changes.

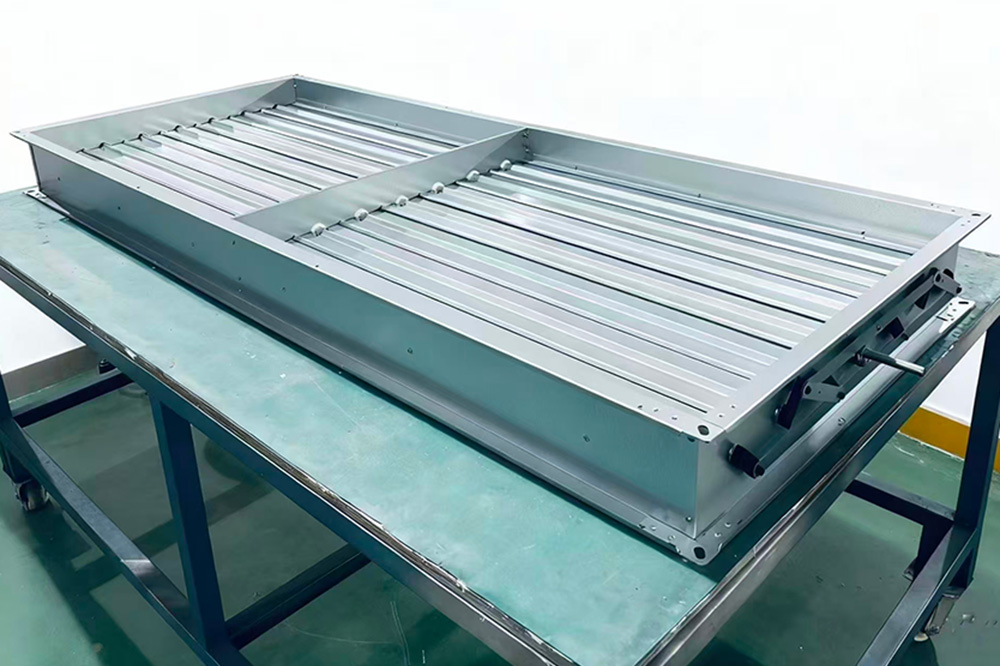

In an opposed blade Volume Control Damper, the blades rotate in opposite directions, maintaining uniform airflow distribution even at partial openings.

This configuration offers smoother airflow control, reduces turbulence, and ensures consistent pressure across ducts—an essential feature in systems requiring precise airflow regulation such as cleanrooms or laboratories.

The parallel blade Volume Control Damper operates with all blades moving in the same direction. This results in a faster change in airflow volume but less uniform distribution compared to opposed blade models.

It’s widely used in exhaust systems, smoke extraction, or applications where rapid response to airflow changes is needed. Despite its simplicity, it remains one of the most cost-effective solutions in industrial HVAC systems.

Depending on duct geometry, Volume Control Dampers can be round or rectangular. Round dampers provide smooth airflow and less leakage, while rectangular dampers offer flexibility for integration into large duct systems.

At SHENGWO Machinery, we provide both shapes with custom sizes and materials, manufactured using CNC precision cutting and sheet metal fabrication to ensure perfect fit and performance for every installation.

The performance, durability, and reliability of a Volume Control Damper depend greatly on the materials used in its construction. Choosing the right material is crucial for achieving long-term stability, corrosion resistance, and mechanical strength—especially in industrial HVAC systems where dampers are exposed to varying temperatures, humidity, and chemical environments.

At SHENGWO Machinery, each Volume Control Damper is made from high-quality materials that meet international standards. Our team ensures that every product undergoes strict inspection during cutting, welding, and assembly to guarantee both durability and accuracy. We understand that different applications require different material characteristics, which is why we offer multiple options tailored to environmental and functional needs.

Stainless Steel 304 / 316: Ideal for industrial HVAC systems, marine environments, and areas exposed to moisture or corrosive air. These grades provide excellent corrosion resistance and a long lifespan, even under continuous operation.

Galvanized Steel: A cost-effective and strong option widely used in commercial buildings and standard ventilation systems. The zinc coating provides decent rust resistance and maintains good airflow performance.

Aluminum Alloy: Lightweight yet strong, aluminum dampers are perfect for applications such as cleanrooms, laboratories, or pharmaceutical plants where hygiene and smooth surface finishes are essential.

Our in-house sheet metal fabrication and CNC machining capabilities allow us to produce dampers with exceptional precision, ensuring a perfect fit with duct systems and stable airflow regulation. With laser cutting, bending, and finishing, SHENGWO guarantees that each Volume Control Damper meets both technical and aesthetic expectations.

The versatility of Volume Control Dampers makes them essential across a wide range of industries and building types. Wherever air distribution, temperature control, or ventilation safety is important, a damper is necessary to regulate and balance the system.

In commercial buildings, these dampers help maintain comfort by distributing air evenly across multiple zones and floors. In industrial facilities, they manage exhaust systems, remove fumes, and ensure proper ventilation for worker safety. Data centers depend on them to maintain cooling efficiency and prevent overheating of sensitive electronic equipment.

Commercial Buildings – Ensure balanced air delivery to every office, lobby, or meeting space, reducing hot or cold spots.

Factories and Workshops – Regulate exhaust systems and manage intake air for efficient and safe working environments.

Data Centers – Control and direct airflow precisely around racks to maintain optimal equipment temperature.

Hospitals and Laboratories – Maintain sterile and controlled air environments to prevent contamination.

Warehouses and Industrial Plants – Support large-scale ventilation and temperature management, improving productivity and safety.

A well-designed Volume Control Damper not only ensures comfort but also contributes to energy efficiency by reducing fan load and optimizing HVAC system performance. Over time, this results in significant cost savings and improved environmental sustainability.

A high-quality Volume Control Damper must balance functionality, structural integrity, and efficiency. Its design is crucial to ensure smooth operation and consistent airflow across a range of pressures and temperatures. At SHENGWO Machinery, every damper is engineered using advanced CAD modeling, CNC fabrication, and laser cutting, allowing us to achieve high precision and repeatability in production.

When designing a Volume Control Damper, engineers must consider airflow behavior, system compatibility, and long-term reliability. A small design flaw—such as uneven blade gaps or weak frame sealing—can lead to significant air leakage, noise, or pressure loss, affecting overall HVAC system efficiency.

Blade Angle Accuracy: Determines how precisely airflow can be controlled at varying duct pressures.

Leakage Prevention: Tight blade sealing minimizes unwanted air loss and boosts energy savings.

Corrosion Protection: Applying powder coating or using stainless steel prevents rust and extends service life.

Ease of Installation: Modular, customizable designs allow fast installation and reduced labor costs.

Automation Ready: Optional integration with actuators for BMS connectivity, enabling smart airflow management.

Through meticulous engineering and quality inspection, SHENGWO ensures every Volume Control Damper operates smoothly, quietly, and reliably in demanding environments.

Installing a Volume Control Damper in an HVAC system delivers a wide range of functional and operational benefits. Beyond just controlling airflow, it supports energy efficiency, enhances safety, and extends the life of the entire ventilation system.

Each benefit plays a role in improving performance while reducing overall maintenance and operational costs. Below are the key advantages of incorporating high-quality dampers—especially those manufactured by SHENGWO Machinery.

By adjusting the damper blades, users can precisely regulate air distribution in various zones. This ensures consistent temperature and pressure levels, creating a more comfortable environment and reducing uneven airflow problems.

A properly adjusted Volume Control Damper helps reduce wasted airflow, minimizing the workload on fans and blowers. Over time, this translates to significant energy savings and lower carbon emissions.

Controlling airflow effectively also helps reduce system noise caused by turbulence and vibration. Balanced pressure means quieter operation, which is essential for offices, hospitals, and residential spaces.

During maintenance or upgrades, individual ducts can be isolated by closing the damper. This prevents the need to shut down the entire system, increasing uptime and convenience for facility managers.

A balanced system places less strain on HVAC components such as fans, filters, and motors. This leads to fewer breakdowns and longer service life, improving the overall return on investment.

In short, a Volume Control Damper is not just a component—it’s a key to achieving efficient, sustainable, and comfortable air management.

As a leading manufacturer of sheet metal and CNC components, SHENGWO Machinery delivers customized Volume Control Dampers that combine performance, durability, and value. With years of expertise in HVAC metalwork and precision machining, we have established long-term partnerships with clients worldwide who trust our consistent quality and fast delivery.

2500㎡ Modern Factory: Our production area has doubled to meet increasing demand, enabling us to handle both standard and large-scale orders with shorter lead times.

Certified Quality: SHENGWO holds ISO9001 and ISO14001 certifications from a UK-accredited body, ensuring adherence to global manufacturing standards.

Trusted by Fortune 500: We are a SAM-audited green supplier for Schneider Electric, one of the world’s top 500 companies.

National Recognition: Certified as a National High-Tech Enterprise and a Technology-Oriented SME, reflecting our commitment to innovation.

ERP System Management: Comprehensive digital tracking guarantees production accuracy and on-time delivery.

Core Values: Safety, Quality, Delivery, Cost, and Innovation form the foundation of every SHENGWO project.

Excellent Delivery: Our streamlined production system ensures shorter lead times and faster response to client requests.

Superior Quality: Each Volume Control Damper undergoes rigorous testing for leakage, airflow, and mechanical stability.

Cost Competitiveness: By integrating in-house sheet metal processing and CNC machining, we offer premium quality at competitive prices.

Through precision engineering, strong R&D, and a focus on sustainability, SHENGWO has become a trusted partner for global HVAC integrators and contractors seeking long-lasting and efficient Volume Control Dampers.

Q1. What is the difference between a Volume Control Damper and a Fire Damper?

A Volume Control Damper regulates airflow, while a Fire Damper automatically closes to prevent fire and smoke spread. They serve different safety and control purposes.

Q2. Can Volume Control Dampers be customized?

Yes. At SHENGWO Machinery, we manufacture custom Volume Control Dampers in various materials, sizes, and blade configurations to fit your duct design.

Q3. How often should a Volume Control Damper be maintained?

Routine inspection every 6–12 months is recommended to ensure proper blade movement and prevent dust buildup that affects airflow.

Q4. What material is best for industrial applications?

For factories, Stainless Steel 304 or 316 is ideal due to its corrosion resistance and strength under high pressure and temperature.

Q5. Do motorized dampers save energy?

Yes. Motorized Volume Control Dampers automatically adjust airflow, minimizing energy waste and optimizing HVAC system efficiency.

A Volume Control Damper is a vital component in maintaining efficient, comfortable, and safe indoor air quality. Whether for industrial plants, commercial buildings, or specialized environments, selecting the right damper and manufacturer ensures long-term performance and reliability.

At SHENGWO Machinery, we combine precision sheet metal fabrication, CNC machining, and innovation to deliver high-performance, custom Volume Control Dampers worldwide.

Looking for a reliable Volume Control Damper manufacturer?

Contact SHENGWO Machinery to discuss your project requirements and experience superior quality, fast delivery, and competitive pricing.