Precision Hardware Customized Solutions Manufacturer

Contents

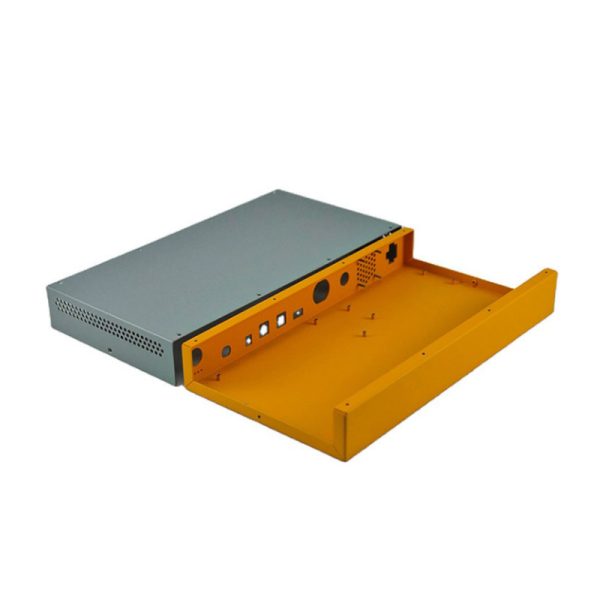

Sheet metal fabrication is a core manufacturing process for producing stainless steel cabinets used in industrial, commercial, and infrastructure applications. Through precise metal forming and assembly, sheet metal structures are transformed into durable enclosures that protect equipment, improve system organization, and support long-term operation.

As a professional provider of precision sheet metal fabrication services, we support customers with customizable solutions tailored to project specifications and volume requirements, helping wholesalers, OEM buyers, and engineering contractors source reliable and high-performance metal components. Our comprehensive capabilities are part of our full suite of manufacturing services, including precision sheet metal fabrication and custom metal solutions.

To explore our range of products, including engineered metal panels and enclosures, view the Stainless Steel Cabinet product details available on our product page.

Sheet metal fabrication is a manufacturing process that shapes flat metal sheets into functional parts through cutting, bending, welding, and surface finishing. In the context of stainless steel cabinet production, these fabrication methods ensure dimensional accuracy, structural integrity, and consistent performance for demanding industrial environments.

The application of advanced processes allows metal components to meet tight tolerances and deliver long-term durability. These fabrication services form the backbone of our metal manufacturing capabilities and are integral to producing engineered products like industrial cabinets and control panels.

Stainless steel is widely chosen for metal cabinet applications due to its superior corrosion resistance, mechanical strength, and aesthetic finish. Cabinets constructed from stainless steel are suitable for environments where moisture, temperature changes, or frequent cleaning are factors.

The versatility of stainless steel also makes it ideal for electrical enclosures, control housings, and industrial equipment cabinets, providing both functional protection and long service life for internal systems.

You can find a variety of stainless steel cabinet specifications and sizes on the Stainless Steel Cabinet product page, which showcases our precision metal hardware solutions.

Manufacturing high-quality stainless steel cabinets involves a series of coordinated fabrication steps:

Precision Cutting – Laser and CNC cutting technologies deliver clean, accurate panel dimensions essential for precise assembly.

Bending and Forming – CNC bending equipment shapes the metal sheets into precise angles and profiles, ensuring components fit together seamlessly.

Welding and Assembly – Skilled welding enhances overall cabinet strength and stability, which is especially important for larger or load-bearing structures.

Surface Treatment – Processes such as polishing, brushing, or powder coating improve corrosion resistance and enhance the appearance of the final cabinet product.

The above steps form a part of our comprehensive precision metal fabrication services, which ensure consistent quality and performance for every manufactured piece.

Stainless steel cabinets manufactured through precision sheet metal fabrication find applications in a wide range of industries, including:

Industrial automation and machinery control systems

Electrical distribution and power management cabinets

HVAC and building management systems

Telecommunications equipment housings

Public infrastructure and outdoor installations

These cabinets provide a secure, organized environment for electrical components, helping reduce maintenance requirements while improving system reliability. Detailed specifications and customization options for these cabinets can be reviewed on the Stainless Steel Cabinet product page.

We offer flexible customization options for stainless steel cabinets and other metal enclosures. Customers can request alterations in:

Cabinet dimensions and configurations

Internal partitions and mounting features

Door types and locking mechanisms

Surface finishes and treatments

Our team works closely with clients to translate design requirements into manufacturable solutions, supporting both OEM and wholesale projects with consistent quality and delivery performance.

These services are part of our broader manufacturing portfolio, which includes other precision metal products and fabrication services tailored for industry needs.

Stainless steel cabinets can be equipped with a variety of features to optimize usability and performance, including:

Ventilation openings to support heat dissipation

Cable entry points for tidy wiring management

Internal mounting brackets and trays

Enhanced sealing for environmental protection

Incorporating these functional elements during the sheet metal fabrication process ensures cabinets meet the specific operational requirements of each application.

Quality assurance is a priority throughout the sheet metal fabrication process. Each stage is monitored to verify material thickness, dimensional tolerances, and finish quality, ensuring that stainless steel cabinets meet performance expectations in industrial use.

This systematic production oversight helps deliver reliable products for long-term operation, whether for electrical enclosures, control panels, or environmental housings.

Choosing an experienced sheet metal fabrication partner provides clear advantages for international buyers and project contractors:

Stable and repeatable product quality across batches

Customization support for design and engineering requirements

Reliable production capacity for bulk and project-based orders

Factory-level pricing and streamlined supply chain support

These benefits help reduce sourcing risks and enhance overall project efficiency. Our precision metal services are designed to support businesses in achieving superior outcomes for industrial fabrication needs.

How does sheet metal fabrication improve cabinet quality?

Precision processes like laser cutting and CNC bending ensure accurate fits, structural strength, and consistent performance across manufactured cabinets.

Can stainless steel cabinets be tailored to specific requirements?

Yes, cabinets can be customized in size, internal layout, and surface finish to match project specifications and operational needs.

Are these cabinets suitable for outdoor environments?

Stainless steel’s corrosion resistance makes these cabinets ideal for outdoor installations and harsh industrial conditions.

Do you support OEM and bulk quantity orders?

Yes, sheet metal fabrication services are designed to support both OEM applications and large-volume orders for long-term supply.

If you are sourcing stainless steel cabinets or require advanced sheet metal fabrication services for industrial applications, we provide reliable manufacturing solutions with flexible customization and professional support.

You can explore the Stainless Steel Cabinet product page for detailed specifications or visit our main Products section to discover a broader range of precision metal solutions.