Precision Hardware Customized Solutions Manufacturer

Author | Shengwo Industry Insights Team

Updated | November 2025

Contents

In modern manufacturing, cutting technology plays a decisive role in determining product quality, efficiency, and cost. Among various methods, Sheet Metal Laser Cutting and plasma cutting stand out as two of the most widely used technologies for shaping and fabricating metal components. Both offer unique benefits, but for industries seeking precision, accuracy, and speed, understanding their differences is essential to choosing the right solution.

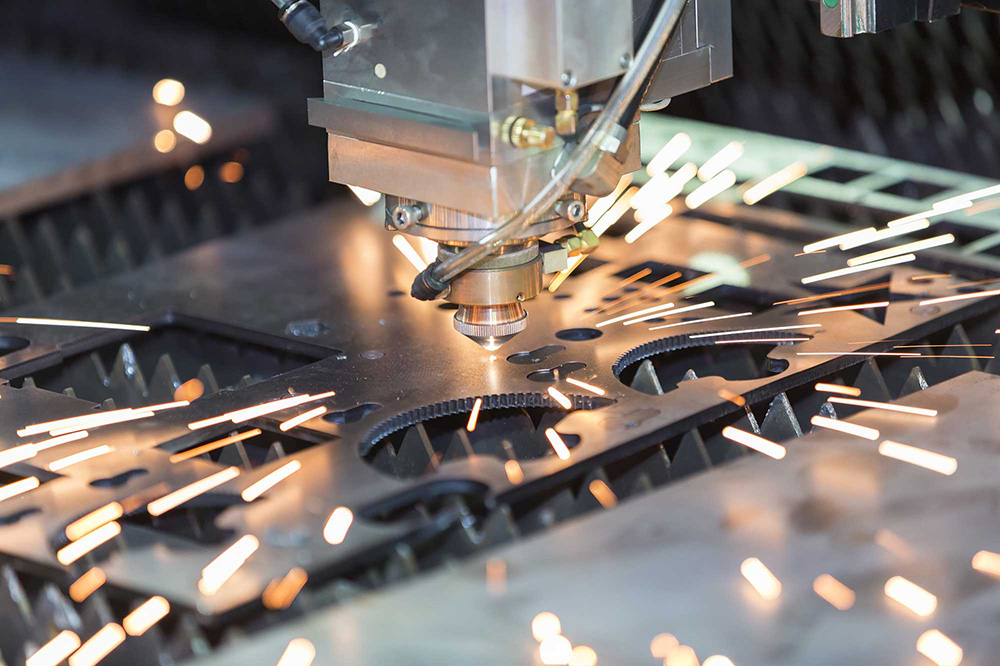

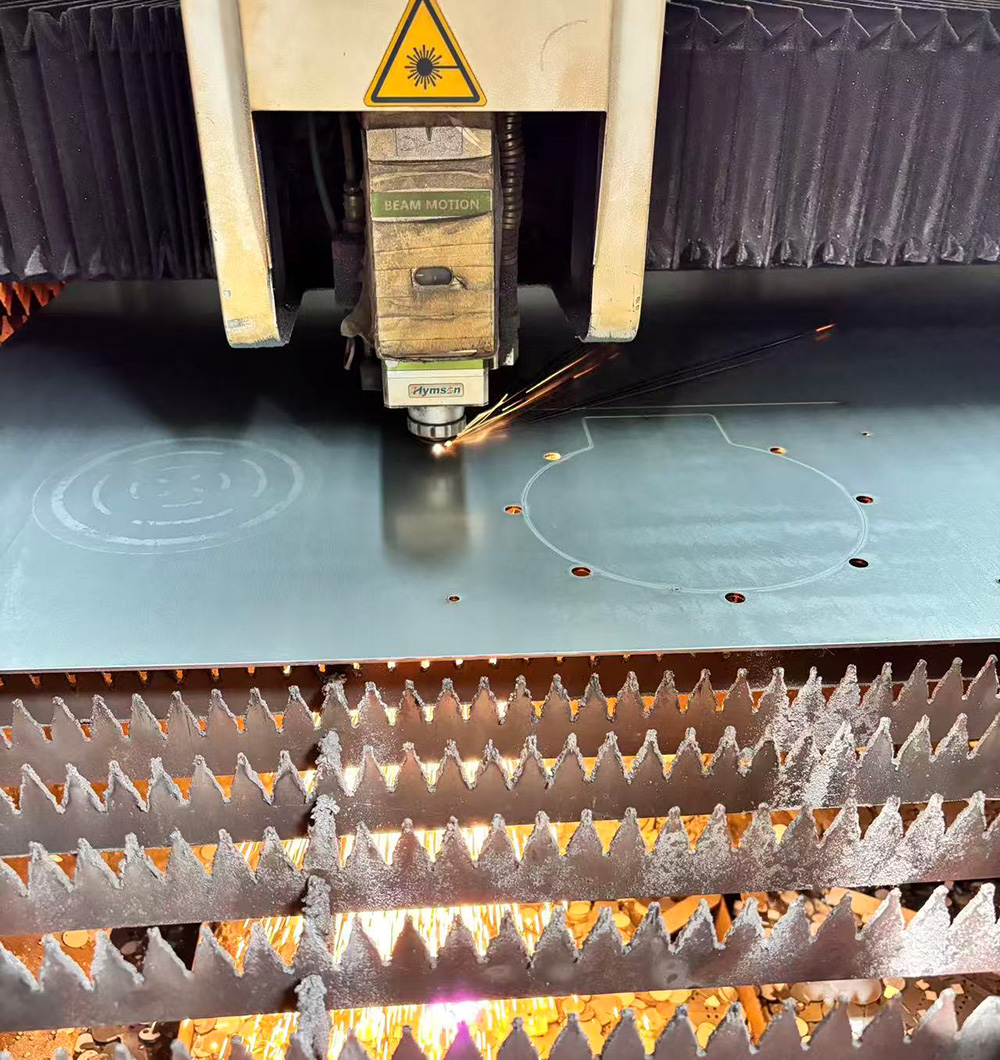

Sheet Metal Laser Cutting uses a highly focused laser beam to melt, burn, or vaporize material, producing clean and precise cuts. The process is computer-controlled, ensuring exceptional repeatability and consistency. Unlike traditional mechanical cutting, laser cutting minimizes material deformation and delivers extremely fine edges.

Modern Sheet Metal Laser Cutting systems can cut stainless steel, aluminum, carbon steel, and other metals with remarkable precision. The cutting thickness can range from 0.1 mm to over 25 mm depending on the laser power. This technology supports a wide range of industrial applications—from electronics and machinery to automotive and architectural fabrication.

Key advantages include:

High precision: Tolerances as tight as ±0.05 mm

Smooth edges: No need for secondary finishing

Flexible cutting: Suitable for complex shapes and small holes

High repeatability: Ideal for mass production and prototyping

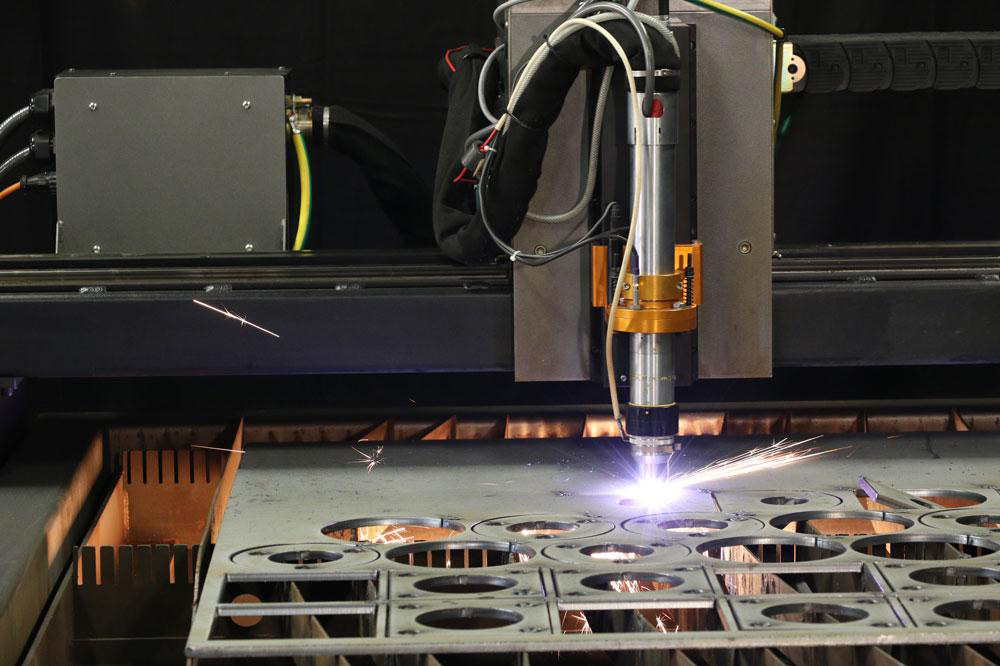

Plasma cutting is another metal fabrication process that uses a high-velocity jet of ionized gas (plasma) to cut through electrically conductive materials. The plasma torch melts and blows away the molten metal, producing a cut that is effective but typically less precise than laser cutting.

While Sheet Metal Laser Cutting offers fine detail, plasma cutting excels in cutting thick metal plates quickly. It is widely used in heavy machinery, shipbuilding, and construction applications where precision is less critical.

Main benefits of plasma cutting include:

High cutting speed for thick materials

Lower equipment cost compared to laser systems

Effective for conductive metals like steel and aluminum

However, it has downsides such as rougher edges, more heat distortion, and the need for additional finishing in many cases.

| Feature | Sheet Metal Laser Cutting | Plasma Cutting |

|---|---|---|

| Cutting Precision | ±0.05 mm | ±0.3 mm |

| Edge Quality | Smooth and burr-free | Rough edges, may require grinding |

| Material Thickness | Best for thin to medium | Best for medium to thick |

| Cutting Speed | Fast for thin materials | Faster for thick materials |

| Heat-Affected Zone | Small | Larger |

| Maintenance Cost | Moderate | Low |

| Automation Compatibility | Excellent | Moderate |

For manufacturers requiring high dimensional accuracy—such as in the electronics, aerospace, or medical industries—Sheet Metal Laser Cutting is the superior choice. Its precision and minimal thermal impact make it ideal for fine and complex parts.

1. Minimal Material Distortion:

Laser cutting produces a narrow heat-affected zone, minimizing warping or deformation. This ensures stable dimensions even for delicate parts.

2. Clean and Consistent Edges:

The beam creates smooth, burr-free surfaces that often don’t require additional finishing—saving both time and labor costs.

3. Compatibility with Modern CAD/CAM Systems:

Laser cutters integrate seamlessly with advanced CAD/CAM software, enabling accurate digital design-to-production transitions.

4. Sustainability and Efficiency:

Laser systems use less energy per unit cut compared to plasma or flame cutting, aligning with green manufacturing trends.

5. Versatility Across Metals:

Whether cutting stainless steel, brass, or aluminum, laser cutting delivers consistent results without tool wear.

For engineers and designers focused on tight tolerances, Sheet Metal Laser Cutting provides the control and repeatability that modern industries demand.

1. Automotive Industry – Producing precision components like brackets, panels, and structural parts.

2. Electronics – Cutting fine metal casings and circuit frames.

3. Architecture – Decorative panels, facade designs, and precision structural elements.

4. Machinery and Equipment – Custom enclosures, mechanical covers, and fixtures.

5. Aerospace – Lightweight, high-strength precision parts.

Each sector benefits from the accuracy, repeatability, and clean cuts offered by Sheet Metal Laser Cutting—allowing manufacturers to improve efficiency and reduce production waste.

At Shengwo Machinery, we provide advanced Sheet Metal Laser Cutting services combined with decades of experience in CNC machining, precision sheet metal fabrication, and custom metal shelving solutions.

Here’s why clients worldwide trust Shengwo:

Expanded facility: Our plant area has doubled to 3000 square meters, supporting higher production capacity.

Green supplier certification: We are a SAM-audited green supplier for Schneider Electric, one of the Global Fortune 500 companies.

Dual ISO certification: ISO 9001 and ISO 14001 (UK-accredited) ensure quality and environmental compliance.

National recognition: Certified as a National High-Tech Enterprise and a Technology-Based SME in China.

Digital management: Our ERP system enables precise production control and on-time delivery.

Performance metrics: We evaluate projects based on safety, quality, delivery, cost, and innovation.

Global focus: We primarily serve international enterprises and export-oriented clients.

Our combination of Sheet Metal Laser Cutting expertise, CNC machining, and custom metal fabrication enables us to deliver end-to-end manufacturing solutions for a wide range of industries.

Q1: What materials can be processed using Sheet Metal Laser Cutting?

A1: It can handle stainless steel, carbon steel, aluminum, brass, and titanium with thicknesses up to 25 mm depending on laser power.

Q2: How accurate is Sheet Metal Laser Cutting compared to plasma cutting?

A2: Laser cutting achieves ±0.05 mm precision, while plasma typically offers ±0.3 mm—making laser ideal for detailed components.

Q3: Is laser cutting suitable for mass production?

A3: Yes, laser systems are highly repeatable and can operate continuously with automated feeding, perfect for high-volume manufacturing.

Q4: What are the limitations of Sheet Metal Laser Cutting?

A4: It may not be cost-effective for very thick materials (>30 mm) or reflective metals unless advanced fiber lasers are used.

Q5: Can Shengwo provide customized laser cutting services?

A5: Absolutely. Shengwo offers custom Sheet Metal Laser Cutting solutions based on client drawings, tolerances, and surface finish requirements.

As industries move toward digitalization and high-precision engineering, Sheet Metal Laser Cutting continues to set new standards in accuracy, speed, and sustainability. While plasma cutting remains effective for thicker plates, laser cutting is unmatched when detail, efficiency, and quality matter most.

If you’re looking for a reliable and professional partner for your next Sheet Metal Laser Cutting project, Shengwo Machinery is here to deliver world-class solutions with a commitment to quality and innovation.

Contact Shengwo today to discuss your project needs and get a customized quote that fits your precision manufacturing goals.