Precision Hardware Customized Solutions Manufacturer

Author | Shengwo Industry Insights Team

Updated | September 2025

Contents

The sheet metal fabrication process has been at the core of modern manufacturing for decades, supporting industries such as automotive, aerospace, construction, electronics, and retail equipment. As we enter 2025, innovation in this field is accelerating faster than ever. The sheet metal fabrication process now integrates advanced automation, digital monitoring systems, robotics, and AI-driven design, allowing manufacturers to achieve higher precision, lower production costs, and faster turnaround times. These advancements are not only transforming how factories operate but are also shaping the competitive landscape for businesses that rely on durable, customizable sheet metal products.

At Shengwo Machinery, we specialize in CNC precision machining, sheet metal fabrication, and custom shelving systems. By adopting the latest innovations in the sheet metal fabrication process, we help global retailers, industrial buyers, and OEM clients achieve scalable and customized solutions based on their specific drawings and requirements. This article highlights the top innovations in 2025 that every manufacturer should know to stay competitive.

One of the most impactful innovations in the sheet metal fabrication process in 2025 is the integration of automation and robotics. Automated bending machines, robotic arms for welding, and AI-guided laser cutters now dominate production floors. This automation reduces the margin for human error, improves consistency in production quality, and enables 24/7 operations without downtime.

For example, robotic welding systems now feature adaptive sensing technology, which automatically adjusts welding speed and angle based on material thickness. In addition, automated bending machines can now handle complex geometries with ease, improving productivity while lowering labor costs. For manufacturers like Shengwo, these technologies mean we can offer clients more accurate, repeatable results, especially for large-volume orders.

Automation not only improves efficiency but also reduces workplace accidents by limiting human interaction with hazardous machinery. In the sheet metal fabrication process, this balance of safety, speed, and precision is becoming a standard requirement for global competitiveness.

Artificial Intelligence (AI) is revolutionizing how manufacturers approach the sheet metal fabrication process. AI-powered software can simulate complex bending and cutting sequences before production even begins. By doing so, manufacturers avoid costly errors, reduce material waste, and shorten product development cycles.

In 2025, AI design tools can automatically recommend the most efficient cutting paths, bending sequences, and even suggest alternative material thicknesses that maintain strength while reducing costs. Manufacturers benefit by achieving optimized production while customers receive highly cost-effective solutions.

At Shengwo Machinery, our design team works closely with clients who provide detailed CAD drawings. Using AI-driven simulation, we ensure that every design is thoroughly tested in a virtual environment before it reaches the production line. This approach guarantees accuracy, supports customization, and helps us maintain a competitive edge in the sheet metal fabrication process.

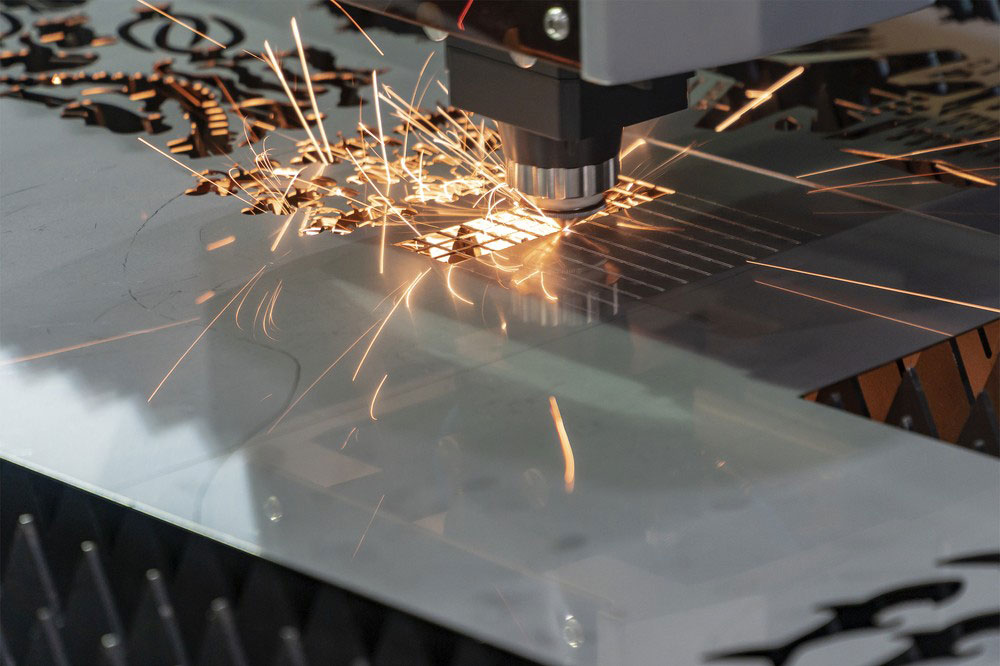

Laser cutting remains a cornerstone of the sheet metal fabrication process, but in 2025, its capabilities have expanded dramatically. New-generation fiber lasers now cut with greater precision, faster speeds, and reduced energy consumption compared to older CO₂ systems. These advancements allow manufacturers to process thicker materials while maintaining smooth, burr-free edges.

High-power laser systems are now integrated with real-time monitoring sensors, which automatically adjust laser intensity to account for variations in material composition. This ensures consistent quality across every cut, regardless of production volume.

For industries that require extremely precise components, such as aerospace or medical equipment, these innovations in laser cutting are invaluable. At Shengwo, our investment in advanced laser cutting equipment allows us to handle diverse materials—including stainless steel, carbon steel, and aluminum alloys—with precision tolerances that meet the strictest client standards.

While 3D printing is often associated with plastics, recent innovations have made it possible to integrate additive manufacturing into the sheet metal fabrication process. Metal 3D printing now allows for the creation of complex prototypes, molds, and fixtures that can be combined with traditional bending and welding techniques.

This hybrid approach is particularly useful for manufacturers who require rapid prototyping. Instead of waiting weeks for a sample to be fabricated using conventional methods, companies can now print prototypes in hours, test them, and immediately move into production.

At Shengwo Machinery, we see 3D printing as a complement to the sheet metal fabrication process. By integrating additive and subtractive manufacturing, we can provide customers with faster turnaround times while maintaining flexibility in design and customization.

Sustainability is no longer optional—it is a requirement for modern manufacturers. The sheet metal fabrication process in 2025 places heavy emphasis on eco-friendly practices, including recycling scrap materials, reducing energy consumption, and implementing closed-loop water systems for cooling and cleaning.

Manufacturers are also exploring lightweight alloys and alternative materials that reduce overall environmental impact while maintaining structural integrity. Smart monitoring systems now track energy use across each stage of the sheet metal fabrication process, allowing companies to implement real-time optimizations that save both costs and resources.

Shengwo Machinery has adopted these sustainable practices by recycling materials during production and utilizing energy-efficient CNC machinery. For customers, this means not only cost savings but also the ability to work with a supplier that aligns with global green manufacturing trends.

CNC machining remains a vital part of the sheet metal fabrication process, particularly in 2025, as demand for micro-precision components increases. Advanced CNC machines now support multi-axis operations, allowing for intricate cuts and highly detailed designs that were once impossible.

These machines are also connected to digital monitoring platforms, which ensure every part produced meets exact specifications. This is particularly critical in industries such as aerospace and medical manufacturing, where even the smallest error can result in product failure.

At Shengwo Machinery, CNC machining is one of our core strengths. We integrate CNC technology into the sheet metal fabrication process to produce custom brackets, enclosures, and mechanical parts. By combining precision machining with sheet metal bending and welding, we deliver complete solutions for clients across multiple industries.

In today’s competitive market, customization is as important as efficiency. The sheet metal fabrication process in 2025 emphasizes flexibility, enabling manufacturers to adapt production lines quickly to meet client-specific requirements.

Shengwo Machinery specializes in providing custom solutions based on detailed client drawings. Whether it’s a unique retail shelving system for global supermarkets or a specialized enclosure for industrial machinery, we tailor our sheet metal fabrication process to meet the exact needs of each customer.

This client-centric approach not only ensures satisfaction but also builds long-term partnerships. By offering flexibility in material choice, finish, and dimensions, Shengwo empowers customers to differentiate themselves in their industries with unique, durable products.

Choosing the right partner for the sheet metal fabrication process can determine the success of your project. At Shengwo Machinery, we combine advanced technology, sustainable practices, and years of experience in CNC precision machining and sheet metal fabrication.

Our advantages include:

Ability to customize products based on client-provided CAD drawings.

Investment in cutting-edge CNC machines, laser cutting systems, and robotic automation.

A dedicated design team that ensures precision and efficiency.

Sustainable manufacturing practices that align with global standards.

Expertise in retail shelving, display racks, and industrial components.

By choosing Shengwo, clients benefit from reliable quality, on-time delivery, and a partner who truly understands the challenges of modern manufacturing.

The sheet metal fabrication process in 2025 is defined by automation, AI, sustainability, and precision. Manufacturers who embrace these innovations will lead in quality, efficiency, and competitiveness.

Shengwo Machinery is at the forefront of these advancements, delivering customized, high-precision solutions for global clients. If you are looking for a trusted partner who can transform your designs into reality with the latest sheet metal fabrication process innovations, contact Shengwo today and let’s build the future together.

Q1:What industries benefit most from the sheet metal fabrication process?

Industries such as automotive, aerospace, construction, retail, and consumer electronics benefit greatly. These sectors rely on durable, precision-engineered sheet metal components.

Q2:Can Shengwo create custom designs based on my drawings?

Yes. Shengwo Machinery specializes in customization and can fabricate products exactly according to customer-provided CAD or technical drawings.

Q3:How does automation improve the sheet metal fabrication process?

Automation improves accuracy, reduces production costs, increases safety, and allows for large-scale production with minimal downtime.

Q4:Does Shengwo support sustainable practices?

Absolutely. We implement eco-friendly manufacturing processes, including recycling scrap materials and investing in energy-efficient machinery.