Precision Hardware Customized Solutions Manufacturer

Author | Shengwo Industry Insights Team

Updated | September 2025

Contents

Sheet metal bending is one of the most critical operations in modern manufacturing, enabling the transformation of flat sheets into functional, durable, and precisely engineered components. The process not only defines the structural integrity of a product but also impacts its visual appeal, cost-efficiency, and usability. Understanding the various Sheet Metal Bending Techniques allows manufacturers to select the right process for specific applications, ranging from industrial machinery to retail display racks. By mastering these bending techniques, manufacturers can reduce waste, improve accuracy, and deliver consistent quality across large-scale production.

At Shengwo Machinery, our expertise in Sheet Metal Bending Techniques enables us to deliver customized solutions that meet international standards. We leverage state-of-the-art CNC machinery and precision engineering, ensuring every bend is executed with tight tolerances. For clients seeking custom shelving, display racks, or precision CNC parts, this knowledge forms the foundation of products that are not only reliable but also cost-effective.

In today’s competitive industrial landscape, precision and reliability are paramount. Sheet Metal Bending Techniques influence everything from product strength to assembly efficiency. If the bending process is poorly executed, manufacturers may face problems such as weakened structural integrity, material cracks, or increased production costs due to rework and scrap. By applying the right bending technique, these risks are minimized, enabling products that stand up to rigorous use in industrial, commercial, and consumer applications.

For manufacturers like Shengwo Machinery, these techniques are not just about shaping metal—they are about ensuring quality and efficiency at every stage. Our mastery of Sheet Metal Bending Techniques allows us to work with multiple materials, including stainless steel, carbon steel, and aluminum, meeting a wide range of customer requirements. We also provide custom fabrication based on customer drawings, ensuring that each solution aligns perfectly with their design and functional goals.

Air bending is among the most commonly used Sheet Metal Bending Techniques, offering flexibility and efficiency for a variety of applications. In this process, the punch presses the sheet into a die without bottoming out, leaving space for the material to flex. This allows manufacturers to achieve multiple bend angles with a single set of tooling, significantly reducing costs and setup times. It is widely used for parts that require varying angles but do not demand extreme precision.

The main advantage of air bending is its cost-effectiveness and adaptability. It consumes less force compared to other methods, which extends tool life and makes it suitable for high-volume production. However, it requires skilled operators and precision CNC machines to achieve consistent results, as springback can affect angle accuracy. At Shengwo, our CNC press brakes ensure precise control over air bending, enabling us to deliver components with exceptional quality for industries ranging from retail shelving systems to industrial equipment enclosures.

Bottom bending, sometimes called “bottoming,” is another important Sheet Metal Bending Technique that involves pressing the sheet metal firmly into the die, eliminating most of the springback effect. This results in a more precise and consistent angle compared to air bending, making it an ideal choice for products where accuracy is critical. It requires higher tonnage and more durable tooling, but the payoff is superior quality and uniformity.

For applications like custom display racks or precision CNC parts, bottom bending ensures repeatability across large production runs. This is particularly important when identical bends are needed across thousands of components. At Shengwo Machinery, our expertise in bottom bending allows us to handle complex projects with strict tolerances, delivering consistent results for clients worldwide. Whether it’s stainless steel for food-grade environments or heavy-duty carbon steel for industrial structures, our team ensures reliability in every bend.

Coining is one of the most precise Sheet Metal Bending Techniques, using high pressure to imprint the punch shape into the metal. Unlike air bending or bottom bending, coining eliminates springback entirely, resulting in extremely accurate angles. It is the preferred technique for parts requiring high precision, such as aerospace components, automotive brackets, or intricate display structures where even minor deviations can compromise assembly.

The trade-off with coining is that it requires significant tonnage and puts stress on both the material and the tooling. However, advancements in CNC technology and durable tooling materials make this technique practical for high-end manufacturing. At Shengwo Machinery, we use coining for projects that demand absolute precision, ensuring clients receive components that exceed industry expectations. This makes us a trusted partner for businesses looking for custom metal solutions that must perform flawlessly in demanding environments.

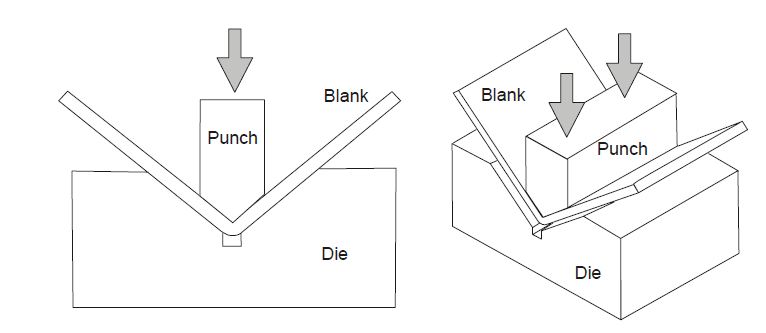

V-bending is perhaps the most recognizable Sheet Metal Bending Technique, named after the V-shaped die used to form the sheet metal. This method is versatile and widely applied in industries requiring standardized angles such as 90°, 120°, or custom configurations. Depending on whether air bending, bottom bending, or coining is applied within the V-die, manufacturers can achieve different levels of precision and efficiency.

Its versatility makes V-bending the go-to method for manufacturers creating retail shelving systems, cabinets, and enclosures. Shengwo Machinery’s advanced CNC press brakes enable us to handle small- and large-scale V-bending projects with accuracy. We work closely with clients to determine the most cost-effective method, balancing precision with production efficiency. Our ability to adapt V-bending to different materials and thicknesses ensures we meet diverse project needs.

Roll bending is a unique Sheet Metal Bending Technique used to form large curves or cylindrical shapes. It involves passing the sheet metal through a series of rollers that gradually bend the material into the desired curvature. This technique is especially useful for producing parts such as cylindrical tanks, tubing, or large structural components.

At Shengwo Machinery, we use roll bending for applications where curved structures are necessary, including architectural elements, industrial containers, or even specialty shelving systems with rounded edges. Our precision CNC roller machines ensure that the bends are consistent and free from distortion, delivering smooth curves that meet the highest standards. This allows us to expand our offerings beyond flat bends, catering to clients who require unique and customized geometries.

As the name suggests, U-bending is a Sheet Metal Bending Technique used to form U-shaped channels. These are commonly used in enclosures, support beams, and custom shelving structures where added strength and rigidity are required. The process involves pressing the metal sheet into a U-shaped die, creating deep channels with straight, parallel sides.

U-bending is essential for manufacturers who need components that combine strength with precision. For example, in shelving and display systems, U-shaped channels provide structural reinforcement while maintaining a clean, modern look. Shengwo Machinery specializes in delivering these components with tight tolerances, ensuring they integrate seamlessly into larger assemblies. Our ability to handle different metals, including aluminum for lightweight designs and steel for heavy-duty applications, makes us a preferred partner for global retailers and industrial equipment wholesalers.

Wiping die bending, also known as edge bending, is a Sheet Metal Bending Technique where the punch presses the sheet against the die, wiping it into shape. This technique is effective for producing flanges and narrow bends along the edges of sheet metal, making it useful in the production of enclosures, brackets, and frames.

While wiping die bending can sometimes introduce defects like material thinning or distortion, the use of precision CNC machines and proper tooling minimizes these risks. Shengwo Machinery applies advanced control systems to ensure accuracy and reduce variability. This method is especially valuable for creating consistent edge bends in custom display racks and industrial shelving systems, where both strength and aesthetic quality are important.

Rotary bending is another versatile Sheet Metal Bending Technique that uses a rotating die to form the bend. Unlike conventional methods, rotary bending allows for sharper bends without damaging the surface of the metal. It also reduces the risk of scratching, making it ideal for parts with decorative finishes such as stainless steel display racks or premium retail shelving.

At Shengwo, we employ rotary bending for projects where surface quality is a priority. This technique ensures smooth, scratch-free finishes while maintaining tight tolerances. Our clients, including supermarket chains and global retail brands, value this method for creating display solutions that combine durability with an attractive appearance. By integrating rotary bending into our services, we ensure that even complex designs can be produced efficiently and cost-effectively.

Folding is a Sheet Metal Bending Technique where a beam or blade folds the sheet metal along a straight edge, typically outside of a press brake. This technique is particularly suited for large panels, thin sheets, or parts requiring multiple bends. It offers high precision and is often used for producing enclosures, housings, and architectural components.

At Shengwo Machinery, we use folding techniques for projects requiring versatility and speed. Our advanced folding machines handle complex multi-bend designs, reducing setup time and increasing efficiency. For clients in retail and industrial sectors, folding provides an efficient way to produce high-quality components that are both functional and aesthetically pleasing.

Offset bending is a Sheet Metal Bending Technique used to create two bends in opposite directions, forming a Z-shaped profile. This technique is valuable for creating clearance, allowing parts to fit together without interference. It is commonly applied in brackets, connectors, and shelving systems where components must interlock seamlessly.

Shengwo Machinery leverages offset bending to produce precise components that integrate perfectly into larger assemblies. Our CNC-controlled offset bending ensures accuracy across large production runs, providing reliability for industries that demand both strength and precision. This capability allows us to support clients in diverse sectors, from supermarket shelving to industrial machinery.

Choosing the right partner for Sheet Metal Bending Techniques is critical to ensuring quality, efficiency, and cost savings. Shengwo Machinery stands out as a trusted manufacturer with years of expertise in CNC precision machining, sheet metal processing, and custom shelving solutions. We work directly with clients’ drawings to deliver customized products that meet exact specifications, offering flexibility in design and materials.

Our capabilities include advanced Sheet metal bending machine, laser cutting machines, and specialized tooling, allowing us to handle projects of any scale. We support global retailers, supermarket chains, store designers, and industrial equipment wholesalers with solutions that combine durability, precision, and cost-effectiveness. With Shengwo, you gain a partner who understands your challenges and delivers results that exceed expectations.

Mastering Sheet Metal Bending Techniques is essential for modern manufacturing, influencing everything from product durability to overall cost efficiency. By understanding and applying the right techniques, manufacturers can deliver superior results that meet global industry demands.

At Shengwo Machinery, we combine technical expertise, advanced equipment, and customization capabilities to provide solutions tailored to your needs. Whether you require custom display racks, retail shelving systems, or precision CNC components, our team is ready to deliver excellence.

Ready to take your project to the next level? Contact Shengwo Machinery today and let us turn your designs into high-quality, precision-engineered products!

Q1: What is the most common sheet metal bending technique?

Air bending is the most common method due to its flexibility and efficiency, though other techniques are used for higher precision.

Q2: How does Shengwo ensure accuracy in sheet metal bending?

We use advanced CNC press brakes and precision tooling, ensuring accuracy within ±0.05–0.1mm, depending on material thickness.

Q3: Can Shengwo handle custom projects based on client drawings?

Yes. We specialize in custom fabrication based on client designs, offering tailored solutions for shelving, display racks, and precision parts.

Q4: What industries benefit most from Shengwo’s sheet metal bending expertise?

We serve supermarket chains, global retail brands, industrial equipment wholesalers, and construction contractors requiring durable, customized solutions.

Q5: Why is choosing the right bending technique important?

The correct technique ensures product quality, reduces waste, saves costs, and guarantees performance in demanding applications.