Precision Hardware Customized Solutions Manufacturer

Contents

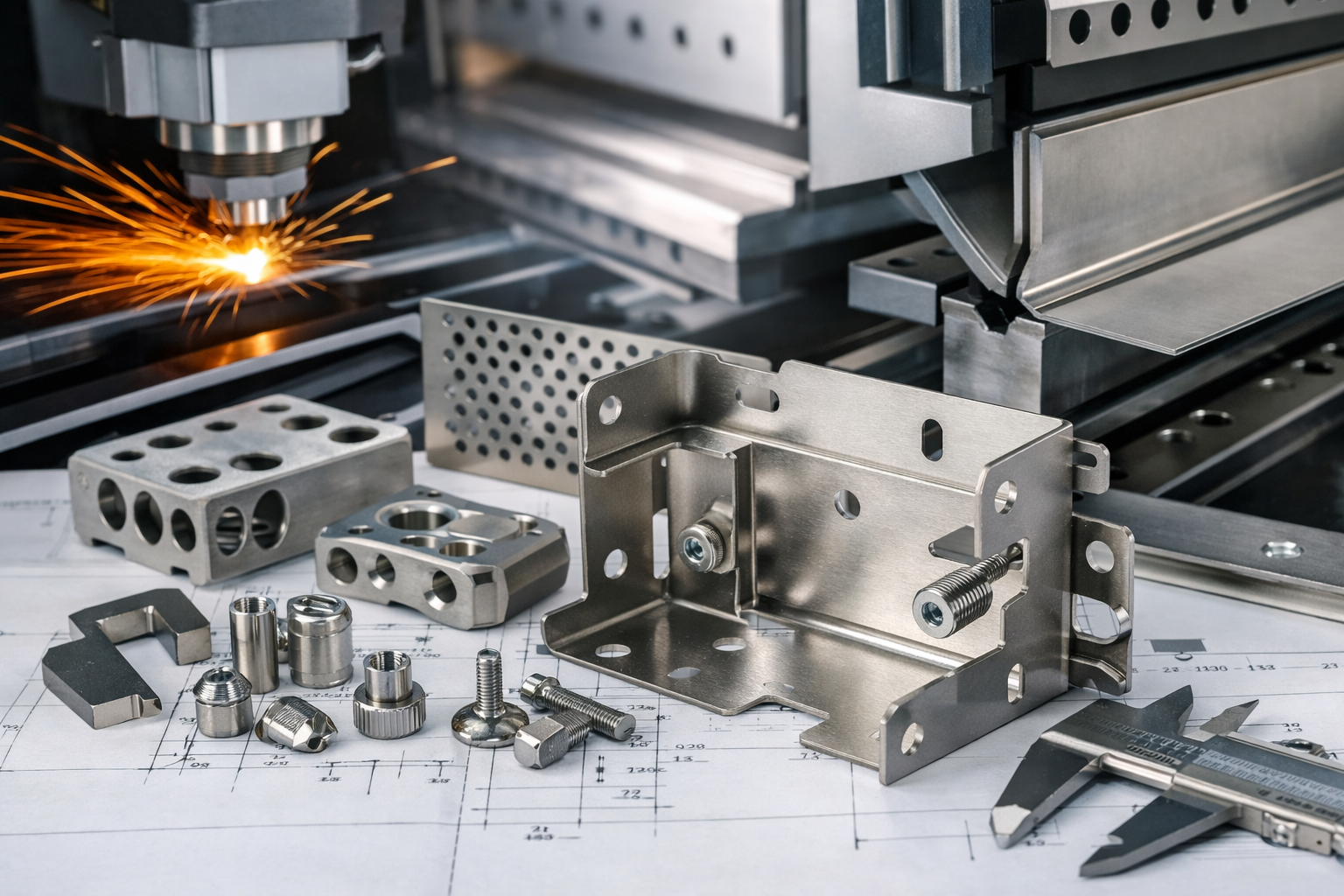

Precision sheet metal parts manufacturing is a critical capability for industries that require accurate dimensions, stable performance, and consistent quality across production batches. From industrial equipment to electrical systems, precisely fabricated metal components ensure reliable assembly and long-term functionality.

As industrial products become more complex, manufacturers increasingly rely on professional suppliers who can deliver tight tolerances, repeatable quality, and scalable production for OEM and wholesale applications.

Precision sheet metal parts manufacturing focuses on producing metal components with strict dimensional accuracy and structural consistency. Unlike general fabrication, precision manufacturing emphasizes tolerance control, process stability, and quality repeatability.

This manufacturing approach is widely used for components that must fit seamlessly into larger assemblies or automated systems.

High-precision metal components are produced through carefully controlled fabrication processes. Each step plays a role in achieving dimensional accuracy and surface consistency.

Core processes typically include:

CNC laser cutting for precise profiles and clean edges

CNC bending for accurate angles and repeatability

Welding and mechanical fastening for structural integrity

Surface finishing for corrosion resistance and durability

These processes enable reliable precision sheet metal parts manufacturing for demanding industrial environments.

Material selection directly affects part performance, lifespan, and application suitability. Commonly used materials include:

Stainless steel for corrosion resistance and hygiene requirements

Cold-rolled steel for strength and dimensional stability

Galvanized steel for electrical and outdoor components

Aluminum for lightweight and thermal performance

Each material is chosen based on application conditions and engineering requirements.

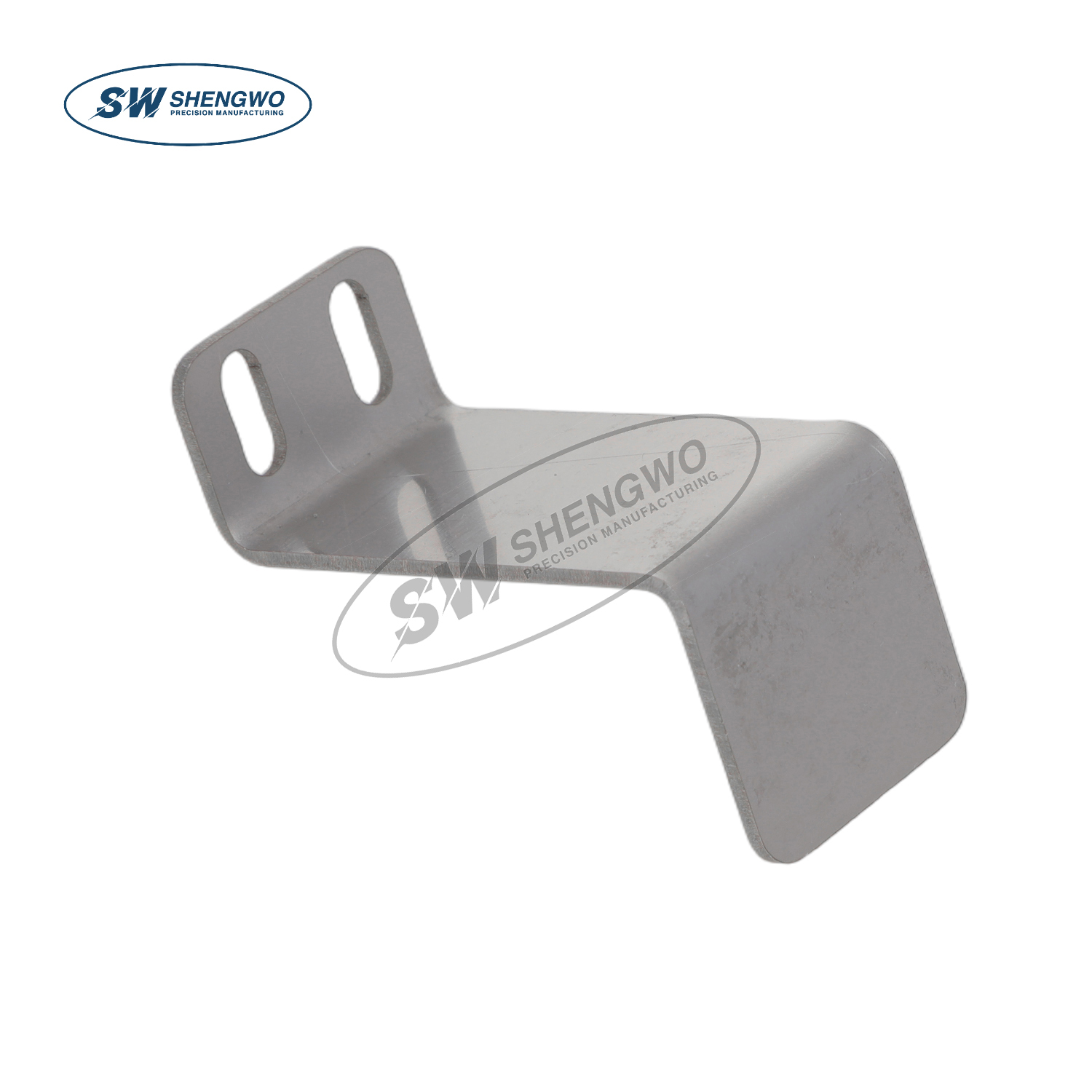

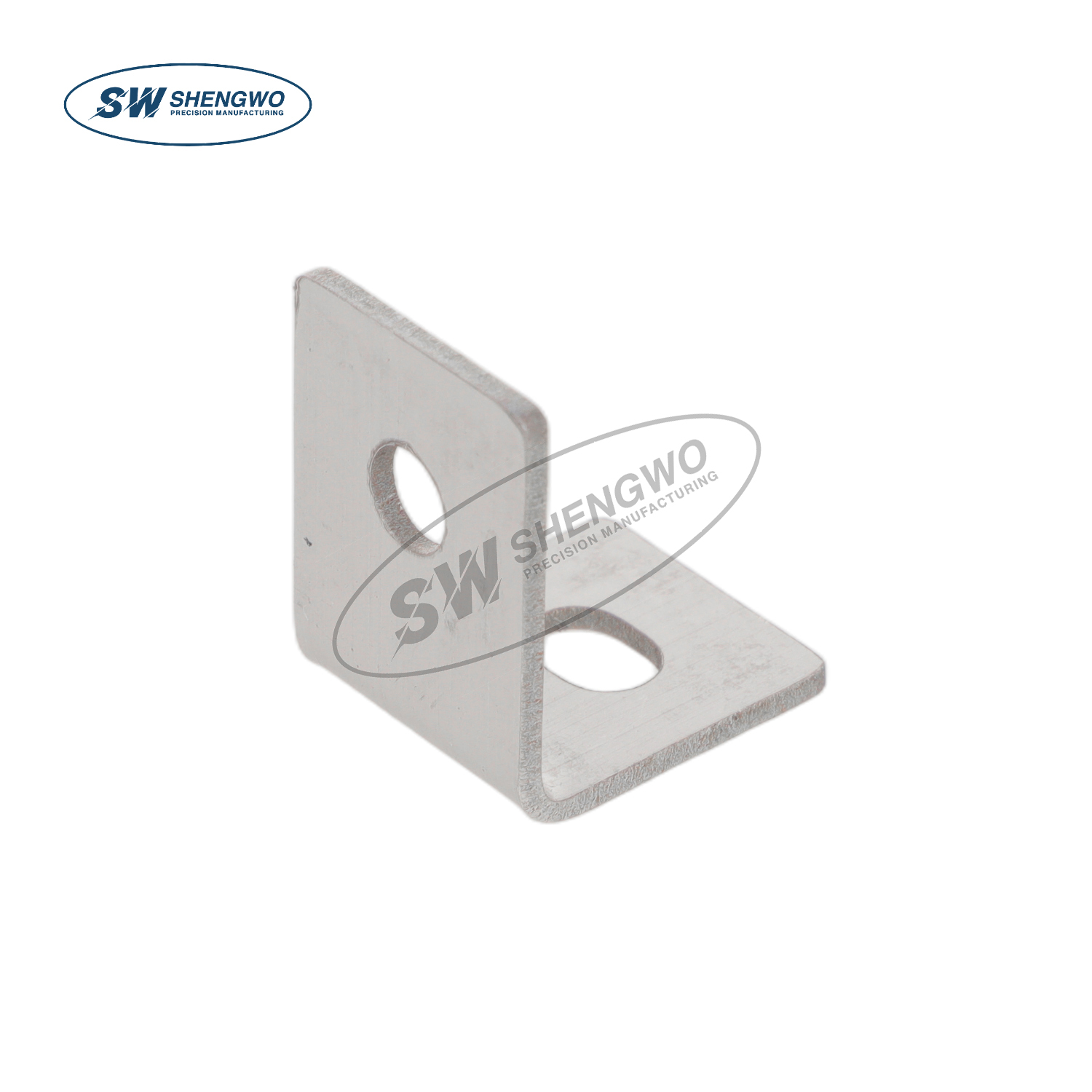

OEM customers often require custom-designed components that meet specific functional and installation needs. Precision manufacturing supports customization without sacrificing consistency.

Customization options may include:

Part dimensions and tolerances

Material thickness and grade

Hole patterns and mounting structures

Surface treatment and finish

Through controlled production workflows, precision sheet metal parts manufacturing supports both prototype development and mass production.

Precision sheet metal components are widely used in:

Industrial machinery and equipment

Electrical control systems and cabinets

Automation and robotics assemblies

Energy and power distribution systems

Commercial and industrial infrastructure

In each application, dimensional accuracy and structural reliability are essential.

Maintaining consistent quality is a key requirement for industrial buyers. Professional manufacturers implement multi-stage quality control systems to ensure reliable performance.

Typical quality assurance measures include:

Incoming material inspection

In-process dimensional verification

Welding and assembly inspection

Final inspection before packaging and shipment

These procedures ensure that precision metal components meet industrial and export standards.

Working with a specialized precision manufacturing supplier offers several advantages for distributors and OEM customers:

Stable quality across large production volumes

Reduced assembly and installation issues

Scalable production capacity for bulk orders

Reliable lead times for long-term cooperation

A trusted precision sheet metal parts manufacturing partner supports efficient supply chains and consistent product performance.

Precision manufacturing contributes to sustainability by reducing material waste and minimizing rework. Accurate production lowers rejection rates and improves overall resource efficiency.

Durable metal components also extend product lifespans, reducing replacement frequency and long-term maintenance costs.

It is the production of metal components with tight tolerances and consistent quality for industrial and OEM applications.

Yes. Precision manufacturing supports customized dimensions, materials, and finishes based on technical drawings.

Professional manufacturers support both small-batch production and high-volume OEM orders.

Industries include manufacturing, electrical systems, automation, energy, and industrial infrastructure.

Precision sheet metal parts manufacturing is essential for producing reliable, high-quality components used in industrial and OEM applications. Through advanced fabrication processes and strict quality control, professional manufacturers deliver components that meet demanding technical requirements.

Selecting an experienced precision manufacturing partner ensures consistent quality, scalable production, and long-term value for global B2B customers.