Precision Hardware Customized Solutions Manufacturer

Author | Shengwo Industry Insights Team

Updated | November 2025

Contents

Finding a reliable Precision CNC Machining manufacturer is one of the most critical decisions for any engineering team, product developer, or procurement department. The right partner not only delivers high-tolerance CNC parts but also provides the engineering support, manufacturing capability, and long-term production stability required for continuous cooperation. In many modern industrial projects, companies expect suppliers to assist in optimizing drawings, providing cost-saving solutions, and ensuring the parts can seamlessly integrate into complex assemblies. A dependable manufacturer ultimately becomes a strategic partner who helps reduce risks, shorten development cycles, and improve overall product quality.

Today’s projects often combine CNC machining with sheet metal fabrication, custom structural components, industrial racks, air valves, and electrical enclosures. This means your supplier must be more than just a CNC machine shop—they need to be a comprehensive precision manufacturing factory with multi-process integration. Many industries now require hybrid solutions rather than single-process components, so choosing a partner with broader capabilities allows smoother project execution. When a supplier can handle multiple processes in-house, the chances of misalignment, errors, or communication issues are greatly reduced, providing smoother production flow from prototype to mass production.

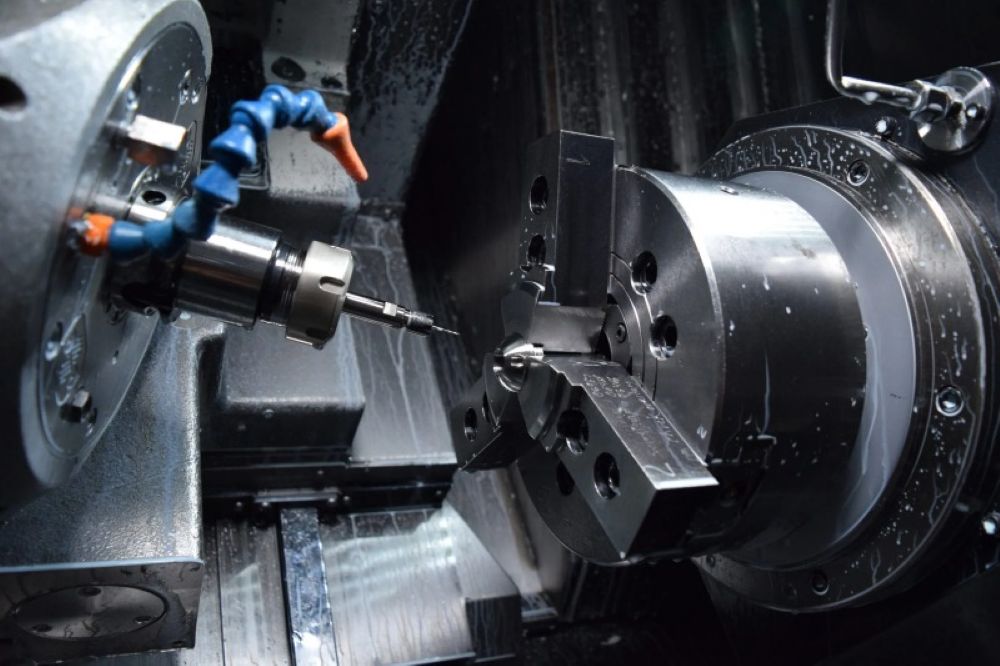

The foundation of a qualified supplier lies in its CNC machining capability. When assessing a partner, consider their equipment, team expertise, stability in mass production, and quality control system. A factory with diverse and advanced machinery can better adapt to complex geometries, high-precision requirements, and tight delivery schedules. Moreover, the ability to maintain consistent performance across different materials—such as aluminum, stainless steel, brass, and engineering plastics—is vital. A manufacturer with proven stability in both prototype development and high-volume production ensures long-term reliability for your supply chain.

A professional CNC factory should have:

3/4/5-axis machining centers

CNC turning lathes

Milling & drilling centers

Automated material feeding systems

Precision measurement tools

Advanced equipment reflects a manufacturer’s ability to handle complex geometries, deep cavities, thin-wall structures, and multi-surface machining. Additionally, a well-maintained machine fleet ensures stable production efficiency and repeatability. When a supplier continuously upgrades machinery and adopts automation, it demonstrates long-term commitment to precision and productivity, which directly benefits customers requiring high accuracy and fast turnaround.

For most industrial applications, precision tolerance is the core requirement. You should ask:

What is the achievable tolerance?

Can tolerance remain consistent in batch orders?

Do they have specialized QC engineers?

Which inspection tools are used?

A good partner should consistently achieve ±0.01mm–±0.03mm. Beyond numeric tolerance, the supplier must also control tool wear, thermal deformation, and material stability. A factory that understands process optimization can prevent dimensional drift during long production runs. This ensures every batch of parts meets your engineering specifications without unexpected variation, which helps avoid downtime and costly assembly issues.

In real industrial projects, CNC machining alone is often not enough. You also need processes such as sheet metal fabrication, laser cutting, bending, welding, and surface finishing. This is why buyers prefer integrated manufacturers. Multi-process capability allows centralized control over production schedules, reduces transportation delays, and ensures consistent quality across different component types. Whether you are developing a prototype or preparing for large-scale manufacturing, a one-stop supplier eliminates unnecessary steps, lowers communication complexity, and ultimately shortens the project lead time significantly.

When a manufacturer can provide CNC machining plus sheet metal plus welding plus assembly, you gain benefits such as faster delivery, consistent quality, reduced cost, and minimized logistics risk. For example, a project may include CNC brackets, sheet metal housings, custom racks, air valves, and electrical cabinet structures. Working with multiple suppliers increases the risk of dimensional mismatches or delayed delivery. An integrated factory, however, ensures every component is produced under unified standards. This improves overall compatibility and guarantees smoother assembly during on-site installation or final product integration.

Industry certifications are one of the strongest indicators of a manufacturer’s reliability. A professional Precision CNC Machining supplier should hold recognized international certifications that demonstrate consistent quality control and strong environmental management standards. Certifications not only prove technical capability but also reflect the company’s commitment to stable production, risk control, and long-term customer cooperation. Many global buyers specifically require suppliers to meet certain certification standards before entering their supply chain, which makes this an important factor in selecting the right partner. A certified manufacturer gives clients greater confidence in product consistency and compliance with industry regulations.

When choosing high-level Precision CNC Machining partners, it’s essential to confirm whether they are certified with ISO9001 (Quality Management) and ISO14001 (Environmental Management). These certifications show that the factory has established strict management systems, standard operating procedures, and continuous improvement mechanisms. Certification by internationally recognized agencies ensures that every product is manufactured under controlled processes, reducing risk for customers. ISO systems also enhance traceability, meaning issues can be identified and solved quickly, which is particularly crucial for critical industrial parts requiring flawless precision.

Being an audited supplier to Fortune 500 companies such as Schneider Electric shows a level of credibility that only advanced manufacturers can achieve. For customers seeking high-quality Precision CNC Machining, this is a strong assurance that the supplier meets international safety, quality, and sustainability standards. Passing strict SAM audits indicates that the factory maintains stable quality, reliable delivery, and eco-friendly operations. This level of recognition demonstrates not only technical strength but also the company’s ability to support global enterprises with strict procurement requirements and long-term cooperation expectations.

A strong engineering team is an essential factor when selecting a Precision CNC Machining manufacturer. Engineers help optimize drawings, improve manufacturability, and provide technical guidance during the entire project cycle. Their role goes beyond simply interpreting a drawing; they identify potential risks, recommend cost-saving modifications, and ensure that every detail aligns with the customer’s intended performance. A skilled engineering team reduces trial-and-error, speeds up prototype development, and ensures mass production stability. This makes them an indispensable partner in modern industrial product development.

An experienced manufacturer should provide detailed DFM feedback. This includes evaluating wall thickness, machining angles, tolerances, assembly fit, and structural strength. Engineers who understand both the machining process and product application can suggest improvements that reduce machining difficulty, enhance part durability, and lower overall production cost. The goal of DFM is not only to produce parts accurately but also to optimize them for better performance and long-term reliability. A thoughtful DFM review helps prevent issues during mass production, resulting in fewer revisions and shorter production cycles.

Top Precision CNC Machining suppliers should provide recommendations on material selection, heat treatment, surface finishing, and machining sequences. These technical insights help customers achieve better mechanical strength, corrosion resistance, and product longevity. Whether the part requires anodizing, powder coating, sandblasting, or special surface textures, a knowledgeable supplier should guide customers to choose the most suitable process. Material selection also impacts machining stability, so a factory with deep technical experience can help avoid warping, cracking, or deformation—issues that often occur when machining complex components or thin-wall structures.

When choosing a Precision CNC Machining manufacturer, one of the most important evaluation factors is the capability of its equipment and production technology. Advanced equipment ensures tighter tolerances, faster cycle times, and more stable machining quality. Modern factories continuously upgrade machinery to maintain competitiveness and support complex projects with higher accuracy requirements. Examining a manufacturer’s machine list, automation level, and maintenance system can help customers understand whether the supplier is capable of handling diversified part geometries, heavy production volumes, and long-term manufacturing programs. A facility with strong machining technology also reduces defect rates and ensures consistent output for demanding industrial applications.

A top-tier Precision CNC Machining supplier should use high-speed CNC machining centers, lathes, grinding machines, and other automated equipment. Automated systems improve precision, minimize human error, and enhance production efficiency. In addition, smart manufacturing technologies such as digital monitoring and production data tracking allow real-time quality control and predictive maintenance. These systems ensure that production remains stable even during large-volume orders. A factory with automation also offers improved repeatability, which is critical for industries such as aerospace, automotive, and electronics where even minor deviations can impact overall product performance.

A manufacturer with larger production space is often better equipped to handle diverse Precision CNC Machining projects. For example, factories like ours that have expanded to 2,500 square meters—a 100% increase—can house more advanced equipment and dedicated operation zones. This expansion supports efficient workflow, cleaner material routing, and enhanced storage systems. Greater space also allows separation of machining, inspection, packaging, and assembly areas to avoid cross-contamination and maintain process consistency. A scalable facility ensures the manufacturer can handle urgent orders, multi-project operations, and long-term customer growth without capacity restrictions.

Reliable Precision CNC Machining requires strict quality control at every stage—from raw materials to final inspection. A capable manufacturer invests in advanced measuring equipment and employs trained quality inspectors to maintain consistent standards. Quality control should include incoming material checks, in-process inspections, tolerance verification, and final testing before shipment. Strong QC systems protect the customer from receiving defective or inconsistent products, reducing rework and improving project efficiency. When evaluating suppliers, customers should look for clear quality manuals, inspection processes, and documented test results that reflect transparency and reliability in manufacturing.

Top manufacturers use coordinate measuring machines (CMM), height gauges, calipers, projectors, and other precision instruments to ensure every component meets specifications. In-process inspection—performed during machining rather than only at the end—helps detect issues early and prevents mass-production defects. This is essential for Precision CNC Machining, where even small deviations can affect assembly fit and overall functionality. High-quality measuring systems also allow traceability, letting customers track inspection records for long-term reliability. With the use of digital measurement tools, manufacturers can maintain consistent accuracy, minimize waste, and ensure superior product performance.

When selecting a supplier for Precision CNC Machining, certifications such as ISO9001 and ISO14001 demonstrate that the manufacturer follows internationally recognized quality and environmental management standards. These certifications indicate a structured approach to process control, documentation, and continuous improvement. Companies certified by reputable UK-accredited bodies further show credibility and strong compliance with global expectations. For customers, this creates confidence that their parts will be produced with consistency, traceability, and professional oversight. Manufacturers with such certifications also tend to have better risk-mitigation systems, ensuring stable quality even during high-volume or long-term production contracts.

Efficient production management is essential when working with Precision CNC Machining manufacturers, especially for clients with tight schedules or complex project timelines. A well-organized factory uses clear planning systems, material scheduling, and manpower coordination to ensure every process step runs smoothly. Customers should evaluate how suppliers plan capacity, manage workload fluctuations, and track production status. A manufacturer with strong production management not only delivers on time but also anticipates potential delays before they occur. This level of control significantly reduces project risks and enhances cooperation between the customer and supplier.

Manufacturers using ERP systems ensure transparent tracking, real-time monitoring, and precise control over each stage of Precision CNC Machining production. ERP integrates procurement, machining schedules, quality inspections, and inventory management into a single digital platform. This reduces human error and enables data-driven decision-making, improving efficiency and accuracy. Customers benefit from better communication, faster updates, and consistent documentation throughout the project. With ERP, manufacturing teams can quickly identify bottlenecks, optimize workflows, and coordinate tasks, providing a smoother and more dependable service experience for clients requiring precision-engineered components.

Speed is a critical advantage when selecting Precision CNC Machining partners. Manufacturers with shorter lead times demonstrate operational efficiency and strong internal coordination. Fast response capability helps customers handle urgent orders, engineering changes, or last-minute design modifications. This flexibility is especially valuable in industries such as automation, telecommunications, and machinery manufacturing. Responsive suppliers ensure less downtime and smoother transitions during product development cycles. When a manufacturer commits to both speed and accuracy, customers gain a competitive advantage in bringing new products to market faster.

Cost is always an important factor in choosing Precision CNC Machining manufacturers, but the lowest price does not always mean the best value. Customers should consider the overall manufacturing capability, quality stability, lead time, and long-term reliability when evaluating costs. A competitive supplier provides transparent pricing, efficient production processes, and optimized material usage without compromising precision. By selecting a manufacturer that balances cost and quality, clients can reduce rework, minimize delays, and achieve better overall project economics. Sustainable cost competitiveness ensures that the customer receives precision-engineered components at fair prices while maintaining performance expectations.

Shengwo Machinery stands out as a reliable partner for Precision CNC Machining, sheet metal fabrication, and custom industrial component manufacturing. Our 2500 m² facility—expanded by 100%—is equipped with advanced machines, digital management systems, and a professional engineering team capable of handling complex projects. We proudly serve top-tier global companies and maintain strict quality controls across every stage of production. Whether clients require CNC parts, custom brackets, electrical panels, air dampers, or sheet metal enclosures, we offer comprehensive and cost-efficient solutions. Our experience across multiple industries ensures customers receive consistent manufacturing quality, dependable communication, and measurable long-term value.

Lead time is essential in modern manufacturing, and Shengwo Machinery is built around fast-response operations. With upgraded equipment, optimized production planning, and full ERP management, we provide significantly shorter delivery cycles for Precision CNC Machining and custom fabrication projects. Our rapid response capability allows us to support urgent modifications, prototype acceleration, and small-batch production without delays. By maintaining efficient coordination between procurement, machining, welding, and assembly, we ensure customers experience stable timelines even during peak seasons. This reliability helps clients reduce downtime, accelerate product development, and improve their overall project efficiency.

Quality is the foundation of our operations at Shengwo Machinery. With ISO9001 and ISO14001 certifications from a UK-accredited body, every Precision CNC Machining component undergoes strict quality inspections, including dimensional checks, material validation, and surface finish auditing. Our skilled technicians follow standardized procedures to ensure accuracy and repeatability from the first piece to the final batch. Whether the project involves stainless steel parts, aluminum CNC components, galvanized steel enclosures, or plastic-metal hybrid assemblies, we guarantee consistent results. This commitment to quality gives customers confidence in long-term cooperation and reduces the risk of rework or performance failures.

Shengwo Machinery provides exceptional cost competitiveness by optimizing processes, improving operational efficiency, and reducing waste through ERP-based management. Our well-structured workflows—from laser cutting and CNC machining to bending, welding, and assembly—allow us to deliver high-value solutions for a wide range of Precision CNC Machining projects. We focus on achieving the ideal balance between material usage, production speed, and precision so customers receive durable, accurate parts at reasonable prices. With long-term improvement programs and continuous technology investment, we help clients maintain budget control without compromising quality or project performance.

Choosing the right Precision CNC Machining manufacturer is essential to achieving accuracy, reliability, and cost efficiency for any industrial project. The ideal partner should have advanced equipment, quality certifications, strong engineering capabilities, and a proven management system that supports on-time delivery.Shengwo Machinery meets all these criteria while offering additional advantages such as fast lead times, certified quality assurance, and scalable production capacity. By working with a professional, experienced manufacturer, customers can reduce project risk, enhance product performance, and speed up time-to-market.

Ready to start your CNC machining or custom fabrication project? Contact Shengwo Machinery today and let our engineering team support your success from concept to completion.

Q1: What types of materials can you use for Precision CNC Machining?

We work with a broad range of materials including aluminum, stainless steel, carbon steel, brass, copper, and engineering plastics. Each material is processed using dedicated cutting strategies and optimized tooling to ensure maximum precision. Whether customers require aerospace-grade aluminum parts, durable stainless steel brackets, or complex multi-material assemblies, our team provides material recommendations and machining guidance to achieve the best performance and manufacturability for their applications.

Q2: Can you handle both prototype and mass production runs?

Yes. Our factory is equipped to support small-batch prototypes, medium-volume orders, and large-scale continuous production. With flexible scheduling and optimized capacity planning, we can quickly transition from prototype to full production using the same standardized process. This ensures consistency, repeatability, and reduced lead times, making Shengwo Machinery a reliable long-term partner for evolving project requirements.

Q3: Do you provide engineering support for design optimization?

Absolutely. Our engineering team offers DFM (Design for Manufacturability) guidance to help customers improve structural strength, reduce costs, and enhance machining efficiency. Whether it’s tolerance adjustment, material optimization, or assembly simplification, we provide practical recommendations to ensure the final Precision CNC Machining parts are both functional and cost-effective. This added support helps clients improve overall performance and avoid common design issues.

Q4: What inspection methods do you use to ensure accuracy?

We use precision measurement tools such as calipers, micrometers, height gauges, surface roughness testers, and coordinate inspection methods depending on project needs. Each part undergoes visual inspection, dimensional verification, and surface evaluation to confirm compliance with customer specifications. For critical components, we can provide full inspection reports, batch traceability, and customized quality documentation as required.

Q5: Do you offer assembly services for CNC parts and sheet metal components?

Yes. Beyond Precision CNC Machining, we provide complete assembly services including component fitting, fastening, wiring tray installation, and module-level integration. This is especially valuable for customers requiring assembled brackets, mechanical modules, electrical panels, custom enclosures, or integrated metal-plastic parts. Our assembly capability reduces procurement complexity and shortens customers’ supply chain cycles.