Precision Hardware Customized Solutions Manufacturer

Published | March 2025

Contents

In 2025, a supply chain transformation driven by Responsible Sourcing is reshaping the global commercial kitchen equipment parts suppliers.

🔹 Data Warning: WHO statistics show that 30% of foodborne illnesses are linked to substandard metal components (e.g., excessive nickel release from stainless steel).

🔹 Regulatory Pressure: The EU Carbon Border Adjustment Mechanism (CBAM) will impose carbon tariffs on imported kitchen equipment starting in 2025.

🔹 Brand Awareness: McDonald’s has mandated that suppliers achieve Scope 3 carbon transparency by 2030.

As a precision sheet metal manufacturer, we understand that responsible manufacturing is the foundation of supply chain accountability.

📌 Case Study: A Chinese kitchen chain recalled thousands of ovens due to hinge tolerance exceeding 0.4mm, causing sealing failure and incurring losses of over $2 million.

Why is Shengwo Your Responsible Kitchen Equipment Parts Supplier in China?

As a precision sheet metal manufacturer, what defines a responsible supplier?

✅ Certifications & Standards

| Standard | Key Focus | Testing Method |

|---|---|---|

| FDA 21 CFR | Heavy metal migration | ICP-MS mass spectrometry analysis |

| EU 10/2011 | Organic compound leaching | High-temperature immersion testing |

Shengwo collaborates with Baosteel to develop a dedicated supply channel for food-grade 304L stainless steel, with each batch carrying a material traceability code to ensure full transparency and compliance with international food safety standards.

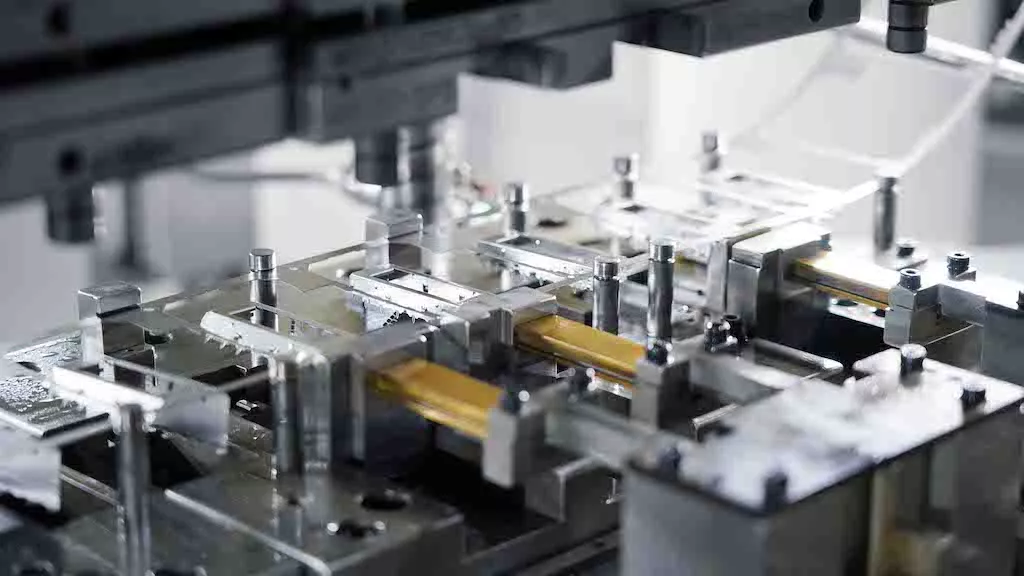

With precision sheet metal processing and modular production, Shengwo provides customized kitchen equipment solutions for high-end restaurants, chain food brands, and five-star hotels, ensuring both durability and performance.

✅ Sustainable Technology Upgrades

| Process | Traditional Method | Green Upgrade | Emission Reduction |

|---|---|---|---|

| Surface Cleaning | Chemical solvents | Water-based nano-cleaners | VOC emissions ↓ 100% |

| Dust Control | External filters | Integrated negative-pressure recycling | Dust leakage < 0.1% |

📌 Achievement: Shengwo’s factory has been recognized as China’s first zero-waste demonstration site in the sheet metal industry.

✅ Defect Prevention & Quality Control

| Process | Potential Risk | Shengwo’s Solution |

|---|---|---|

| Laser Cutting | Burrs causing injuries | Adaptive focal adjustment technology |

| Bending | Stress concentration cracks | Finite element simulation compensation |

📌 Result: Shengwo’s Mean Time Between Failures (MTBF) reaches 62,000 hours, far exceeding the industry average of 38,000 hours.

✅ Scrap Recycling System

Material Flow:

Metal Scrap → Shredding & Sorting → Electric Arc Furnace Melting → Recycled Stainless Steel Coil → Secondary Processing

📌 Impact: In 2023, Shengwo recycled 2,300 tons of scrap steel, reducing ore extraction energy consumption equivalent to planting 54,000 trees.

✅ Technical Excellence: Raising Manufacturing Standards

🔹 AI-Powered Laser Cutting: Dynamic thermal compensation reduces deformation, ensuring ±0.05mm accuracy, far superior to the industry average of ±0.15mm.

🔹 Seamless Welding: TIG + Pulse technology achieves a weld roughness of Ra ≤ 0.8μm, minimizing bacterial adhesion and meeting food-grade hygiene standards.

✅ Commitment to Sustainability

🔹 Carbon Footprint Management: Every product includes a Lifecycle Carbon Emission Label (Scope 1-3) to help clients optimize their supply chain carbon reduction strategies.

🔹 Social Responsibility: 3% of annual profits are invested in a vocational training academy to cultivate the next generation of green sheet metal engineers.

✅ Core Technologies for Food Safety & Equipment Durability

🔹 Electropolishing: Reduces stainless steel surface roughness from Ra1.6μm to Ra0.4μm, cutting bacterial adhesion by 87% and significantly improving hygiene standards.

🔹 Industry Certification: Shengwo’s products are NSF & 3-A certified, serving global food giants like Yum! Brands for over 15 years.

Shengwo enforces rigorous supplier audits focusing on:

🔹 Hazardous Waste Management: Ensuring compliance with HW08 waste cutting fluid disposal certifications.

🔹 Worker Protection: Mandating auto-dimming welding helmets that meet EN379 standards.

Contractual Clauses for Accountability:

🔹 Joint Liability: If a Tier 2 supplier violates standards, the Tier 1 supplier assumes 50% liability.

🔹 Carbon Incentives & Penalties: ¥80 reward per ton of CO₂ reduced; 200% fine for exceeding carbon limits.

📌 Case Study: Shengwo developed a universal oven frame system for a national pizza chain, delivering significant cost savings:

| Metric | Traditional Design | Modular Design | Cost Reduction |

|---|---|---|---|

| Part Count | 127 components | 29 components | ↓77% |

| Repair Time | 4.5 hours | 1.2 hours | ↓73% |

| Inventory Cost | $180,000/year | $40,000/year | ↓78% |

✅ 100,000-Class Cleanroom Standards

🔹 Airborne Particle Control: ≤3,520 particles/m³ (ISO Class 5 compliance).

🔹 Stable Environment: Temperature 23±1°C, Humidity 45±5%.

✅ Digital Traceability System

🔹 RFID Embedded in Every Steel Plate

🔹 457 Parameters Tracked from smelting to final product assembly.

At Shengwo, we integrate high-precision engineering with sustainable responsibility, offering safer, more efficient solutions for the global commercial kitchen equipment parts suppliers.

We go beyond vague commitments—translating responsibility into measurable, enforceable technical standards.