Precision Hardware Customized Solutions Manufacturer

Author | Shengwo Industry Insights Team

Updated | August 2025

Contents

Sheet metal cutting is one of the most fundamental yet technically demanding operations in metalworking and fabrication. Whether you are a construction contractor, equipment wholesaler, or industrial manufacturer, knowing how to cut sheet metal straight is essential to ensure precision, reduce waste, and improve the overall quality of your products.

While manual cutting tools can handle smaller projects, professional sheet metal processing requires advanced technologies such as laser cutting for precise and efficient results. At Shengwo Machinery, we specialize in sheet metal processing, custom racks, and display solutions, leveraging world-class equipment to guarantee accuracy and reliability for global clients.

This comprehensive guide explains different cutting methods, tools, and techniques, along with why Shengwo’s advanced laser cutting solutions set us apart.

When discussing how to cut sheet metal straight, it is more than just achieving a neat edge. Precision in sheet metal cutting impacts:

Structural integrity – Misaligned cuts can weaken the final product.

Aesthetics – Straight cuts ensure a professional finish.

Assembly efficiency – Accurate dimensions mean fewer adjustments during assembly.

Cost savings – Minimizing errors reduces material waste and rework costs.

In industries such as retail shelving, custom display racks, and industrial equipment, even minor inaccuracies can create significant problems downstream.

For smaller-scale projects, knowing how to cut sheet metal straight with manual tools remains important. Common tools include:

Suitable for thin sheets of aluminum or steel.

Best for short, straight cuts.

Requires steady hands to avoid wavering edges.

Ideal for cutting narrow strips.

Works on mild steel and thinner materials.

Can produce clean lines but slower than powered methods.

Cut small pieces at a time, following a line.

Provide better control compared to snips.

May leave slightly jagged edges.

While these tools are cost-effective, they are labor-intensive and not suitable for large-scale industrial production.

For contractors, distributors, and warehouse suppliers handling larger projects, power tools significantly improve speed and consistency.

Use abrasive discs to slice through metal.

Effective for medium-thickness steel.

Requires proper clamping and a steady guide for straight results.

Electric shears offer fast and consistent cutting.

Ideal for long, straight cuts in medium-gauge sheet metal.

Reduce hand fatigue compared to manual snips.

High precision when used with a cutting guide.

Suitable for aluminum and steel sheets.

Requires careful safety measures due to sparks and heat.

These methods improve productivity but still have limitations in accuracy, edge quality, and material thickness.

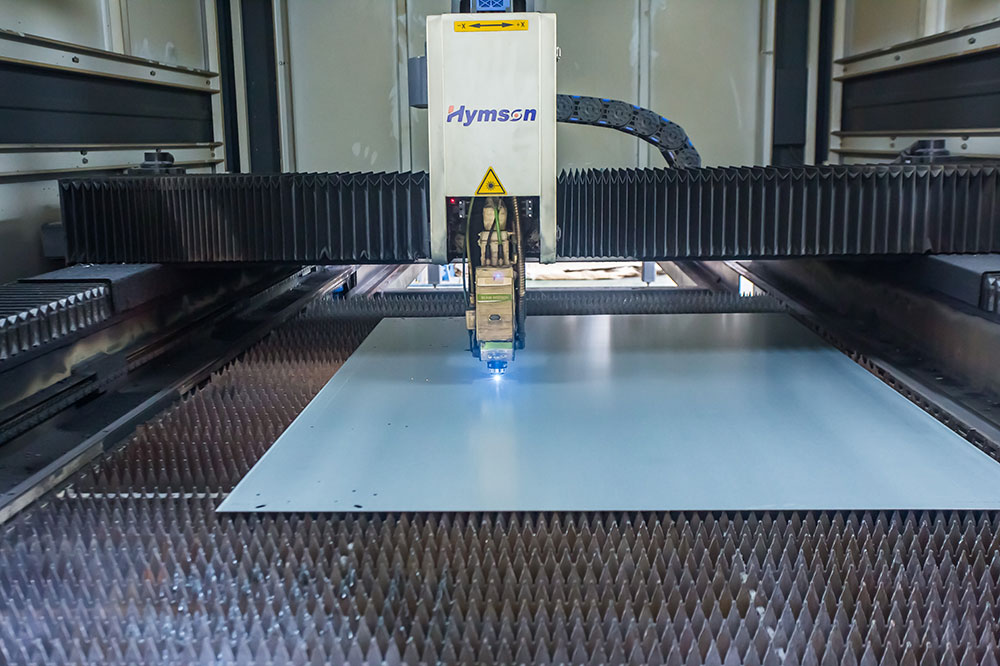

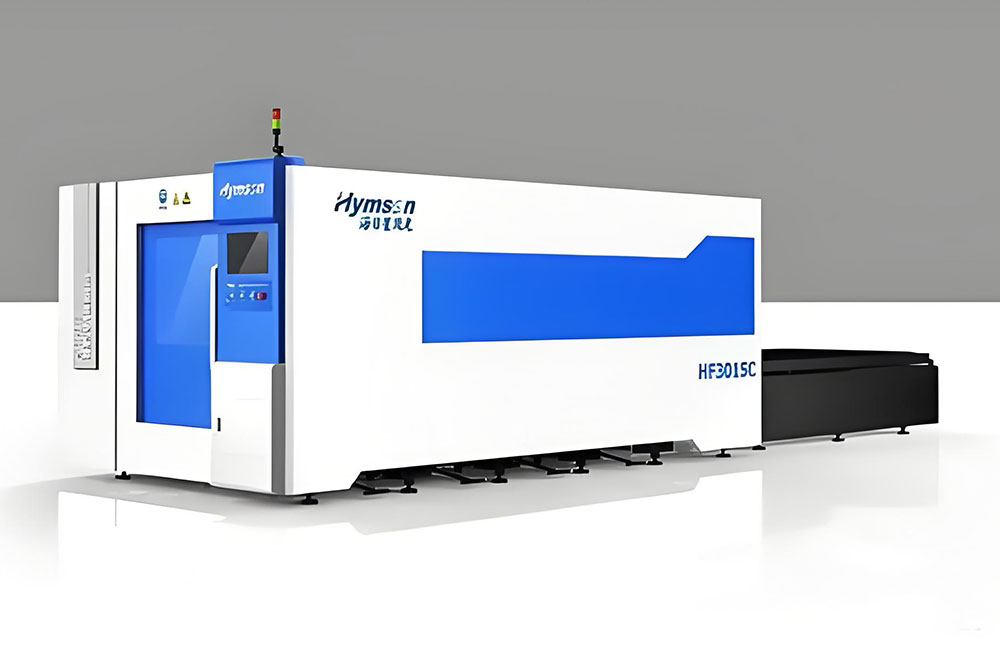

When maximum precision and efficiency are required, laser cutting is the gold standard in modern sheet metal fabrication. Shengwo Machinery has invested heavily in high-performance 3000W and 6000W laser cutting machines to deliver unmatched accuracy for global clients.

3000W Laser Cutting:

Carbon Steel Q235: ≤12mm

Stainless Steel 304: ≤10mm

Aluminum Alloy 5052: ≤6mm

6000W Laser Cutting:

Carbon Steel Q235: ≤25mm

Stainless Steel 304: ≤18mm

Aluminum Alloy 5052: ≤10mm

Cutting Accuracy:

±0.05 mm (for sheets ≤5.0 mm)

±0.1 mm (for sheets ≥5.0 mm)

These specifications guarantee high precision, clean edges, and minimal waste, making laser cutting the most reliable solution for businesses that demand consistent quality.

Whether using manual tools or advanced machinery, the process follows a systematic approach:

Use a straight edge, square, or laser guide.

Double-check dimensions before marking.

Clamp the sheet firmly to prevent movement.

Use protective pads to avoid surface scratches.

Thin sheets: snips or power shears.

Medium thickness: grinders or saws.

High-precision or thick sheets: laser cutting.

Maintain steady pressure for manual tools.

For power tools, keep a straight cutting guide.

Laser cutting follows CAD-based programming for perfect accuracy.

Use a file, grinder, or polishing tool.

Ensures smooth, safe edges for assembly or display.

By following these steps, you can master how to cut sheet metal straight with consistency across different projects.

Precise sheet metal cutting is essential across industries. Some examples include:

Retail Display Racks – Clean cuts ensure seamless assembly and polished aesthetics.

Commercial Shelving Systems – Accurate cuts improve load-bearing stability.

Industrial Equipment Components – High precision avoids assembly delays.

Construction Projects – Sheet metal parts fit perfectly on-site without modifications.

Custom Fabrication – From automotive panels to supermarket fixtures.

In all these cases, straight and accurate cuts directly influence product quality and ROI.

Shengwo Machinery is a trusted manufacturer specializing in sheet metal processing, commercial shelving, and custom display racks. Our expertise combines engineering precision, advanced laser technology, and global service experience.

Our Advantages:

State-of-the-art 3000W and 6000W laser cutting machines.

Precision tolerance up to ±0.05 mm, ensuring consistency.

Support for carbon steel, stainless steel, and aluminum.

Custom fabrication for retail, industrial, and construction clients.

ISO-certified production and 5S management for quality assurance.

Global service, from OEM manufacturing to large-scale distribution.

By choosing Shengwo, clients gain accuracy, efficiency, and long-term reliability—all critical for competitive industries.

Mastering how to cut sheet metal straight is essential for efficiency, cost savings, and high-quality outcomes. While manual tools are useful for small tasks, industrial wholesalers, contractors, and distributors benefit most from precision laser cutting.

At Shengwo Machinery, we deliver high-precision sheet metal cutting, shelving systems, and custom display racks with advanced technology and global service.

Contact Shengwo today to discuss your project and experience the benefits of precision sheet metal cutting tailored to your business needs.

Q1: What is the most precise method to cut sheet metal straight?

A: Laser cutting is the most precise, offering accuracy down to ±0.05 mm.

Q2: Can hand tools achieve professional results?

A: For small projects, yes. However, industrial projects require power tools or laser cutting for consistent results.

Q3: Does Shengwo provide customized sheet metal cutting?

A: Yes, we provide fully customized solutions based on client drawings, sizes, and materials.

Q4: What materials can Shengwo’s laser cutting handle?

A: Carbon steel, stainless steel, and aluminum in a range of thicknesses.

Q5: How does Shengwo ensure consistent quality?

A: Through ISO-certified processes, 5S management, and precision machinery.