Author | Shengwo Industry Insights Team

Updated | November 2025

Introduction to High Precision CNC Machining Design

In today’s competitive manufacturing environment, mastering high precision cnc machining is essential for producing parts that meet strict tolerances while controlling costs. Effective design decisions early in the product development phase can significantly reduce machining time, material waste, and post-processing requirements. This guide outlines actionable tips for designing parts optimized for high precision cnc machining, incorporating Shengwo’s global manufacturing expertise, DFM processes, and Industry 4.0 capabilities.

Understanding High Precision CNC Machining

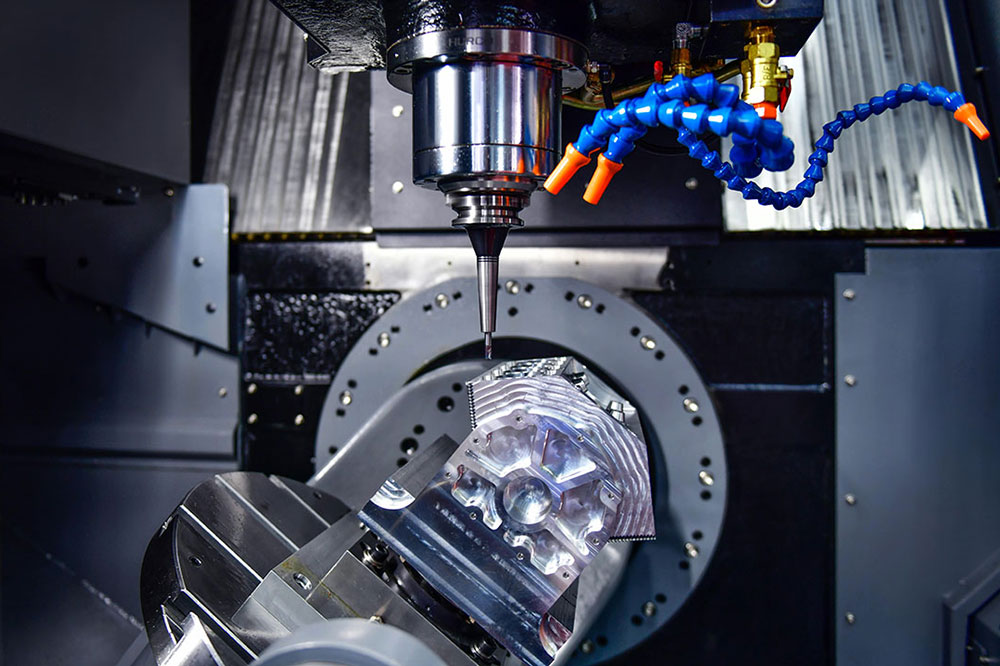

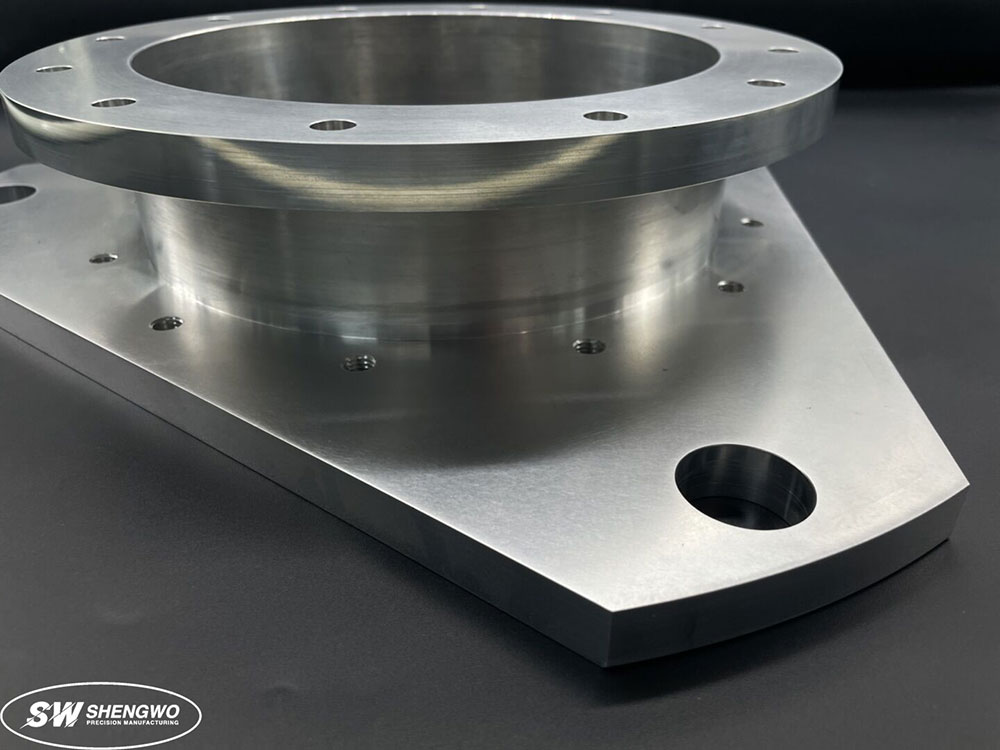

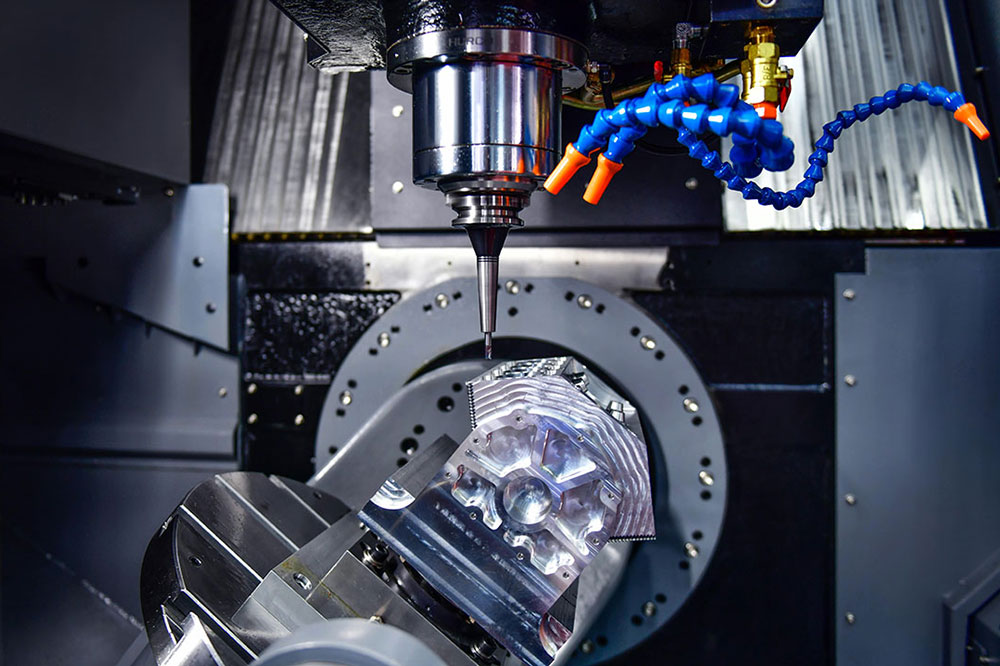

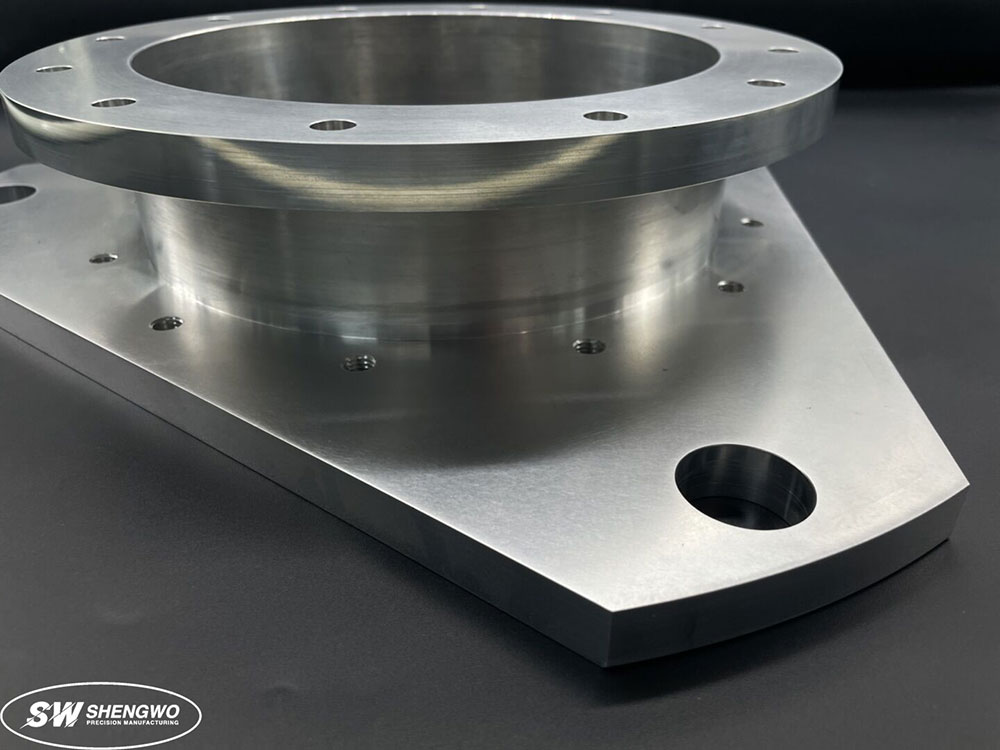

High precision cnc machining refers to machining processes where computer-controlled machines produce complex components with very tight tolerances, often within microns. These processes include milling, turning, drilling, and multi-axis operations. Achieving cost-effective high precision cnc machining depends on careful part design, material selection, tooling, and process planning.

Importance of Design in High Precision CNC Machining

- Well-designed parts reduce setup time, tool changes, and machining passes.

- Good design minimizes scrap and rework, improving production yields.

- Early collaboration with machinists and engineers ensures manufacturability under high precision cnc machining constraints.

- DFM (Design for Manufacturability) enhances cost-effectiveness by aligning design features with equipment capabilities.

Key Design Principles for High Precision CNC Machining

Applying these principles during CAD modeling helps leverage the full potential of high precision cnc machining and reduces overall costs.

Simplify Geometry for Machinability

- Avoid extremely complex features that require multi-axis simultaneous machining if unnecessary.

- Prefer simpler shapes that can be machined with fewer setups.

- When complex features are required, design them to allow standard tool access and reduce non-productive tool motions.

- Use symmetric features where possible to balance machining forces and ease fixturing.

Define Appropriate Tolerances

- Set tolerances only as tight as functionally necessary. Excessively tight tolerances increase machining time and cost.

- Identify critical dimensions requiring high precision; apply looser tolerances to non-critical features.

- Document tolerance zones clearly in drawings or 3D models for high precision cnc machining.

- Work with Shengwo’s DFM team to balance tolerance requirements and machining efficiency.

Relevant Standards:

Material Selection and Its Impact

- Choose materials compatible with high precision cnc machining, considering machinability, stability, and cost.

- Metals such as aluminum alloys (e.g., 6061), stainless steels (e.g., 304, 316), titanium, and specialty alloys have different machining characteristics; consult machinists for optimal choices.

- Consider material stability: some metals may warp under cutting heat; design allowances or use stress-relief processes.

- Leverage Shengwo’s material expertise to select alloys that meet mechanical requirements yet machine efficiently.

Optimize Wall Thickness and Feature Sizes

- Maintain uniform wall thickness where possible to avoid differential material removal rates and deformation.

- Avoid overly thin walls that deflect during machining; ensure minimum recommended thickness based on material.

- For pockets or cavities, maintain consistent depths and radii to facilitate smooth high precision cnc machining.

- Use standard hole sizes and avoid very small diameters that require specialized tooling or slow feeds.

Design for Efficient Fixturing and Setup

- Incorporate features or datum surfaces to facilitate stable fixturing.

- Minimize the number of setups by designing parts that can be machined in fewer orientations.

- Use locating features such as datum bosses or reference flats to reduce alignment time.

- Shengwo’s facility uses advanced jigs and fixtures; early design collaboration ensures compatibility with existing tooling.

Tool Access and Tool Selection

- Ensure adequate clearance for cutting tools and tool holders; avoid deep, narrow slots that limit tool reach.

- Design fillets with radii matching standard tool sizes to reduce custom tooling needs.

- Select appropriate cutting tools (carbide end mills, drills, chamfer tools) based on material and required precision.

- Consider tool wear: materials like hardened steel may require specialized coatings; involve Shengwo’s tooling experts for optimal recommendations.

Surface Finish and Post-Processing Considerations

- Define required surface finishes early; mirror-like or matte finishes influence machining strategy and cycle time.

- For critical surfaces, allow extra machining allowance for final finishing passes.

- Plan for minimal post-machining operations; if polishing or plating is needed, design geometry to facilitate these processes.

- Shengwo’s integrated surface treatment systems (electroplating, spraying) complement high precision cnc machining outputs, offering one-stop finishing solutions.

Thermal and Distortion Control

- Be aware that long machining cycles generate heat; design features to allow cooling strategies.

- Use roughing and finishing passes to remove material gradually, minimizing thermal stress.

- For large or complex parts, consider stress-relief treatments prior to final machining.

- Shengwo’s climate-controlled machining centers help maintain accuracy under varying thermal loads.

Leveraging Industry 4.0 and DFM in High Precision CNC Machining

Advanced manufacturing practices enhance high precision cnc machining efficiency and reliability.

Digital Design for Manufacturability

- Use Shengwo’s self-developed DFM optimization system to analyze CAD models for potential machining issues (undercuts, deep pockets, thin walls).

- Iterate designs based on DFM feedback to reduce machining time and cost.

- Integrate CAD/CAM workflows for seamless toolpath generation aligned with design intent.

ERP-Driven Production Planning

- Shengwo’s ERP system tracks work orders, machine availability, and material inventory in real time.

- Design teams receive immediate feedback on capacity and lead times, enabling realistic project schedules.

- Automated data collection from CNC machines informs continuous improvement in high precision cnc machining processes.

Automation and Robotics

- Automated tool changers, pallet systems, and robotic loading/unloading reduce downtime between setups.

- For high-volume or repetitive parts, automation ensures consistent high precision cnc machining quality and throughput.

- Shengwo’s intelligent production processes incorporate automation to meet tight delivery schedules.

Cost-Saving Strategies in High Precision CNC Machining Design

Design decisions directly affect machining costs; these strategies help achieve cost-effective high precision cnc machining.

Minimize Setup and Changeover Time

- Standardize features across multiple parts to reuse fixturing and toolpaths.

- Batch parts with similar dimensions or machining sequences.

- Use modular fixture designs to accommodate part families, reducing clamping time.

Reduce Non-Value-Added Machining

- Avoid unnecessary features that do not contribute to functionality.

- Simplify geometry to reduce tool engagement time.

- Use through-holes instead of blind holes when possible, as through-holes machine faster.

- Leverage Shengwo’s engineering support to identify and eliminate low-value features in early design phases.

Optimize Material Usage

- Nest multiple parts on larger stock when possible for combined machining operations.

- Choose standard stock sizes to reduce scrap.

- For expensive materials, design parts to maximize yield and consider alternate materials that offer similar performance at lower cost.

Implement Adaptive Machining Strategies

- Use roughing strategies that remove bulk material quickly, followed by precise finishing passes.

- Apply high-speed machining techniques for appropriate materials to reduce cycle times.

- Monitor tool condition and replace proactively to avoid part rejection due to tool wear.

Leverage Supplier Expertise

- Engage Shengwo early in design: their experience with Fortune 500 clients and patented technologies can guide optimal machining approaches.

- Tap into Shengwo’s knowledge base for tool selection, cutting parameters, and fixture design.

- Use pilot runs to validate design and process before full-scale production.

Quality Assurance in High Precision CNC Machining

Ensuring that parts meet specifications is critical for high precision cnc machining success.

In-Process Inspection

- Use probe systems integrated into CNC machines for real-time measurement of critical dimensions.

- Monitor geometric tolerances during machining to detect deviations early.

- Shengwo’s advanced metrology tools (CMM, optical systems) support in-process checks.

Final Inspection and Traceability

- Perform comprehensive inspections on finished parts, including dimensional reports and surface finish verification.

- Maintain traceability records for materials, machine settings, and inspection data.

- ISO-certified quality management at Shengwo ensures consistency and accountability across batches.

Continuous Improvement

- Collect data on machining performance, scrap rates, and tool life to refine processes.

- Hold regular reviews between design and production teams to incorporate lessons learned into future designs.

- Celebrate process innovations and patent-worthy improvements, reinforcing a culture of excellence in high precision cnc machining.

Why Choose Shengwo for High Precision CNC Machining

Shengwo Machinery offers unmatched capabilities in high precision cnc machining:

- Comprehensive One-Stop Services: From in-depth design and DFM optimization to machining, finishing, assembly, and intelligent logistics.

- Advanced Equipment: Modern CNC centers, multi-axis machines, robotic automation, and climate-controlled workshops ensure consistent precision.

- Certified Excellence: ISO certifications, national high-tech enterprise status, and patented processes like the sheet metal surface multi-station system reflect our innovation strength.

- Global Experience: Trusted by Fortune 500 companies such as Schneider Electric, serving industries from automotive and medical to electronics and cloud computing.

- Efficient Production Base: A 2,500 m² facility with ERP-driven management delivers fast prototyping and scalable production while maintaining high quality.

- Collaborative Culture: Diverse, inclusive teams collaborate closely with clients to solve design challenges and achieve cost-effective high precision cnc machining solutions.

- Sustainable Practices: Industry 4.0 focus reduces waste, optimizes energy use, and enhances supply chain resilience, aligning with global sustainability goals.

Partner with Shengwo to leverage our expertise and technology for your most demanding high precision cnc machining projects.

Conclusion: Design for Success in High Precision CNC Machining

Effective design is the cornerstone of cost-effective high precision cnc machining. By applying principles such as geometry simplification, appropriate tolerances, material optimization, fixturing strategies, and DFM collaboration, you can significantly reduce machining costs and improve product quality. Shengwo Machinery’s advanced equipment, Industry 4.0 practices, and experienced teams deliver reliable, precise machining solutions for global clients.

Ready to Optimize Your CNC Machining Projects?

Contact Shengwo Machinery today for expert design consultation, rapid prototyping, and scalable high precision cnc machining services. Let us help you turn your innovative ideas into high-quality, cost-effective reality.

FAQs About High Precision CNC Machining

Q1: What design features help achieve cost-effective high precision cnc machining?

A: Simplify geometry, set tolerances only where needed, enable easy fixturing, and allow standard tool access. Early DFM review with Shengwo identifies cost-saving opportunities.

Q2: How does material choice affect high precision cnc machining costs?

A: Machinability, stability, and stock cost matter. Materials like aluminum machine faster and with less tool wear than harder alloys. Shengwo helps select the optimal material balancing performance and cost.

Q3: How can I reduce machining time without sacrificing precision?

A: Use efficient roughing strategies, minimize setups, employ standard tooling, and optimize toolpaths via CAM systems. Shengwo’s automation and ERP integration further streamline operations.

Q4: What tolerances are realistic for high precision cnc machining?

A: Tolerances depend on machine capability and material; typical high precision CNC can achieve ±0.01 mm or better on critical dimensions. Collaborate with Shengwo to define achievable tolerances based on application.

Q5: How important is fixturing in high precision cnc machining?

A: Extremely important. Stable, repeatable fixtures reduce vibration and misalignment, ensuring consistent accuracy. Shengwo’s jigs and fixture designs are tailored to each part.

Q6: Can Shengwo handle complex multi-axis high precision cnc machining?

A: Yes. Shengwo’s modern multi-axis CNC centers and experienced operators tackle complex geometries, enabling cost-effective production of intricate parts.

Q7: How does DFM optimization improve high precision cnc machining outcomes?

A: DFM identifies potential manufacturing challenges early—such as difficult features or excessive setups—allowing design adjustments that reduce cost and improve yield. Shengwo’s proprietary DFM system automates and accelerates this process.

Q8: What inspection methods ensure quality in high precision cnc machining?

A: In-process probing, CMM checks, optical measurement, and final inspection reports ensure each part meets specifications. Shengwo’s integrated quality systems provide traceability and consistency.