Precision Hardware Customized Solutions Manufacturer

Author | Shengwo Industry Insights Team

Updated | September 2025

Contents

When it comes to protecting sensitive electrical components in industries such as energy, telecom, automotive, and automation, custom metal electrical enclosures are indispensable. These enclosures are not only used to shield electronics from dust, moisture, vibration, and temperature changes but also ensure long-term safety and compliance with international standards. For B2B buyers, choosing the right manufacturer in China is more than just a cost decision—it’s about quality, reliability, customization capability, and long-term partnership.

In fact, as global industries increasingly depend on smart devices, IoT systems, and automation, the need for customized enclosures is growing rapidly. Off-the-shelf options often cannot meet industry-specific requirements such as unique dimensions, special mounting features, or enhanced waterproofing. That’s why working with a trusted manufacturer that can design and produce enclosures tailored to your needs becomes a vital business decision. By choosing the right supplier, companies can significantly reduce downtime, improve product performance, and ensure compliance with global regulations.

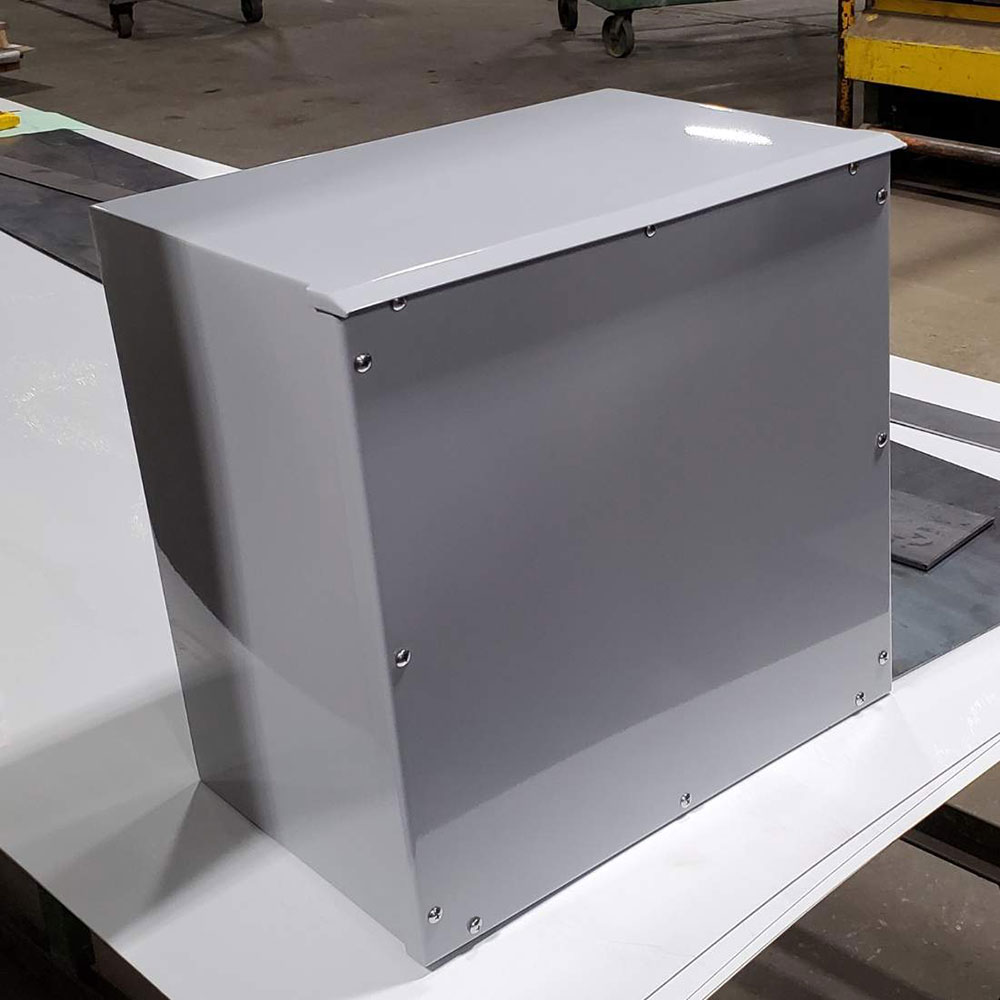

Custom metal electrical enclosures are protective casings designed to house electrical systems, wiring, or delicate electronic assemblies. Unlike standard enclosures, custom solutions are tailored to meet specific dimensions, environmental requirements, or industry certifications. These enclosures can be fabricated from various metals such as stainless steel, aluminum, and cold-rolled steel, each offering unique properties like corrosion resistance, durability, and weight optimization.

Custom designs also allow businesses to integrate advanced features such as cooling systems, cable management, and safety locks. For example, in outdoor applications, a custom metal enclosure may be designed with weather-resistant coatings and additional sealing to prevent damage from rain, dust, or UV exposure. In highly technical industries, enclosures may also include EMI/RFI shielding to protect sensitive electronic signals. The flexibility of customization ensures that the final product matches not only the technical specifications but also the long-term operational environment.

Telecommunication networks – Protecting switches, routers, and fiber equipment

Industrial automation – Housing PLCs, sensors, and controllers

Renewable energy systems – Safeguarding solar inverters, batteries, and monitoring units

Medical equipment – Ensuring safety and reliability of sensitive devices

Transportation – Used in trains, electric vehicles, and charging stations

Beyond these sectors, custom metal electrical enclosures are also widely adopted in oil & gas, aerospace, and data centers, where reliability and safety cannot be compromised. For instance, in offshore oil platforms, enclosures must withstand salty air and extreme pressure, while in data centers, they must allow proper heat dissipation without compromising security. This versatility demonstrates how essential customization is in meeting diverse industry requirements.

China has become a global hub for custom metal electrical enclosures due to its advanced manufacturing infrastructure, cost competitiveness, and skilled workforce. For international buyers, working with a reliable Chinese manufacturer brings several advantages.

Cost Efficiency: Mass production capabilities lower costs without compromising quality.

Customization Flexibility: Manufacturers can design enclosures based on your drawings or requirements.

Advanced Technology: CNC machining, sheet metal fabrication, and powder coating ensure precision and durability.

Faster Lead Times: Established supply chains and large production capacity help reduce delivery times.

Global Experience: Many Chinese suppliers are experienced in working with international B2B clients and meeting export standards.

In addition, Chinese manufacturers often provide integrated services—from design to surface finishing and packaging—which reduces the need for multiple suppliers and simplifies logistics. This vertical integration enables faster turnaround times and better cost control. Furthermore, China’s continuous investment in Industry 4.0, automation, and smart manufacturing technologies has raised production efficiency and accuracy, making its suppliers competitive with global leaders in quality while still maintaining cost advantages.

Selecting the right partner requires thorough evaluation. Here are the most critical factors B2B buyers should consider:

A strong manufacturer should have advanced CNC machining, sheet metal fabrication, laser cutting, welding, and surface treatment capabilities. Look for ISO-certified processes and automated equipment that ensure consistency.

Additionally, ask about the manufacturer’s design-for-manufacturability (DFM) expertise. An experienced supplier won’t just follow drawings blindly; they will suggest improvements to reduce costs, optimize performance, and increase the durability of your custom metal electrical enclosures. The ability to combine engineering knowledge with advanced machinery is a strong indicator of long-term reliability.

One of the main reasons to choose custom metal electrical enclosures is flexibility. Check whether the manufacturer provides design assistance, CAD support, and prototyping services. The ability to turn customer drawings into functional products is a sign of expertise.

Some manufacturers even offer digital twin technology and simulation services, allowing buyers to visualize how the enclosure will perform under real-world conditions. This proactive approach reduces risks during production and ensures that the final enclosure perfectly matches operational needs.

High-quality enclosures must withstand extreme conditions. Ensure the manufacturer conducts rigorous inspections—such as IP rating tests, salt spray tests, and vibration resistance checks. Certifications like CE, UL, and ISO reflect international compliance.

Quality assurance doesn’t end at the factory floor. Reliable manufacturers will also provide traceability for materials, inspection reports, and compliance documentation, which is particularly important for industries like medical and aerospace. Having a robust quality management system not only ensures performance but also builds trust between supplier and client.

Reliable delivery is crucial for global buyers. Ask about raw material sourcing, inventory capacity, and delivery timelines. A transparent and efficient supply chain prevents project delays.

Manufacturers with long-term relationships with raw material suppliers can ensure stable pricing and consistent quality. This is especially important during global supply chain disruptions, where only experienced manufacturers can maintain timely delivery and competitive pricing.

For overseas buyers, communication is essential. A reliable Chinese manufacturer should provide responsive English-speaking support and be proactive in solving issues.

Beyond language skills, it’s equally important to have transparent project management. Many professional manufacturers now provide online tracking systems, regular updates, and dedicated account managers to ensure smooth communication throughout the project lifecycle.

Shengwo Machinery is a professional manufacturer specializing in sheet metal fabrication, CNC parts, and custom display racks. Over the years, we have developed deep expertise in custom metal electrical enclosures for global B2B clients.

Advanced Facilities: Equipped with CNC machining centers, laser cutting, bending, and TIG/MIG welding machines.

Engineering Expertise: We work closely with clients, turning their drawings into high-precision, customized enclosures.

Strict Quality Control: From raw material selection to final inspection, every step is monitored for accuracy and durability.

Customization Service: Whether stainless steel, aluminum, or cold-rolled steel, we tailor enclosures based on environmental needs.

Global B2B Experience: We understand the expectations of international buyers and provide efficient, transparent communication.

Unlike many competitors, Shengwo offers complete one-stop solutions, from concept design and prototyping to mass production and global shipping. Our team is skilled at balancing technical performance with cost-effectiveness, ensuring you always receive maximum value.

Powder coating, anodizing, and galvanization

Rapid prototyping for small batch testing

Cost optimization without compromising quality

Packaging and shipping support for global logistics

By choosing Shengwo, you get more than a supplier—you gain a long-term partner dedicated to your success. Our mission is to help clients around the world achieve reliable, cost-effective, and customized enclosures that meet industry-specific demands.

Choosing the right custom metal electrical enclosures manufacturer in China is critical for the success of your project. From technical capability and customization to quality assurance and reliable communication, every factor matters. Shengwo Machinery offers all these advantages and more, ensuring that our clients receive enclosures that are precise, durable, and tailored to their unique needs.

Ready to start your project? Contact Shengwo Machinery today for a free consultation and let us turn your designs into high-quality custom metal electrical enclosures!

Q1: What is the typical lead time for custom metal electrical enclosures?

A: Depending on complexity and volume, lead times range from 2–6 weeks. Shengwo provides flexible schedules to meet urgent project needs.

Q2: Can Shengwo manufacture enclosures based on my CAD drawings?

A: Yes, we specialize in custom fabrication based on customer drawings and specifications. Our engineering team ensures designs are optimized for functionality and durability.

Q3: What materials are most commonly used for custom metal electrical enclosures?

A: Stainless steel, aluminum, and cold-rolled steel are the most popular, chosen based on corrosion resistance, weight, and application environment.

Q4: How does Shengwo ensure product quality?

A: We perform multiple inspections, including dimensional checks, surface finish tests, and IP-rated waterproofing tests, ensuring every enclosure meets international standards.

Q5: Does Shengwo provide OEM and ODM services?

A: Absolutely. We support both OEM and ODM projects, offering flexibility for branding, packaging, and design modifications.

Q6: Can Shengwo handle large-scale bulk orders?

A: Yes. With our modern facilities and strong supply chain, we can manage small-batch prototypes as well as high-volume production runs, ensuring consistent quality across all quantities.