Precision Hardware Customized Solutions Manufacturer

Contents

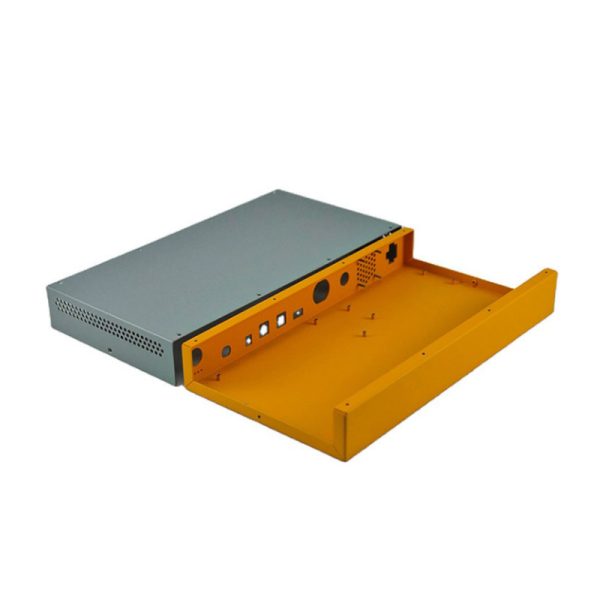

Custom industrial metal enclosures are critical for protecting sensitive electrical equipment, machinery, and industrial systems. These enclosures provide structural strength, corrosion resistance, and long-term reliability, making them indispensable for OEM, wholesale, and B2B projects.

In today’s industrial landscape, manufacturers increasingly rely on custom metal enclosure solutions to meet exact specifications and compliance requirements. Choosing the right supplier ensures consistent product quality, scalability, and timely delivery for international clients.

Custom industrial metal enclosures are designed and fabricated based on specific client requirements. Unlike standard enclosures, these are tailored for:

Precise dimensions to fit machinery or electrical systems

Material selection suited for operational environments

Mounting options for easy integration

Surface treatment to resist corrosion and wear

Custom enclosures ensure equipment protection, safety, and compliance with international industrial standards. They also improve installation efficiency and reduce maintenance needs.

Material choice directly affects durability, weight, and performance. Professional suppliers commonly work with:

Stainless steel: corrosion-resistant, hygienic, and durable for industrial and outdoor applications

Cold-rolled steel: strong and dimensionally stable for structural applications

Galvanized steel: ideal for electrical components and outdoor environments

Aluminum: lightweight, thermally conductive, and corrosion-resistant

Each material is selected based on the operational environment, load capacity, and OEM requirements, ensuring optimal performance.

To meet the high standards of B2B clients, custom industrial metal enclosure manufacturers leverage advanced fabrication technologies:

CNC Laser Cutting: precise profiles, clean edges, and repeatable accuracy

CNC Bending & Forming: ensures consistent angles and shapes for assembly

Welding & Mechanical Assembly: structural integrity for industrial use

Surface Finishing: powder coating, galvanization, or painting for durability and aesthetics

These processes allow suppliers to deliver enclosures that are not only functional but also ready for direct integration into industrial systems.

OEM brands and industrial buyers often require bespoke solutions. Typical customization services include:

Dimensions & tolerances: exact size to fit machinery or electrical panels

Mounting and cutout patterns: pre-drilled holes for switches, displays, or connectors

Material thickness & type: depending on load, corrosion resistance, or thermal performance

Surface finishing: powder coating, galvanization, or painting for protection and branding

With these options, B2B clients can streamline assembly, reduce on-site modifications, and improve product consistency.

Custom industrial metal enclosures serve multiple industrial sectors:

Electrical & control systems: protect circuit boards, switchgear, and power distribution units

Manufacturing machinery: safeguard critical components in automated equipment

Automation & robotics: house sensors, controllers, and motor drives

Energy & power systems: enclose batteries, transformers, and converters

Commercial & industrial infrastructure: protect instruments, lighting controls, and monitoring systems

By offering precision and durability, these enclosures reduce downtime, maintenance costs, and risk of equipment failure.

Global B2B buyers value suppliers who implement strict quality control:

Incoming material inspection: verify grade, thickness, and properties

Dimensional verification: ensure tolerances meet design specifications

Assembly & welding inspection: prevent structural defects

Final product testing: check finishing, fit, and operational readiness

Certified manufacturing processes ensure that industrial metal enclosures meet ISO, CE, or other relevant standards, giving buyers confidence in product reliability.

Partnering with a professional industrial metal enclosure supplier provides tangible advantages:

Consistent quality across bulk orders – crucial for OEM projects

Scalable production – small batches or high-volume wholesale supported

Reduced supply chain risk – reliable lead times and production planning

Technical support & customization – engineering guidance for design and manufacturing

Long-term partnership – maintain consistency across product lines

These benefits help B2B buyers streamline operations, reduce costs, and meet project deadlines efficiently.

Durable enclosures contribute to sustainability by:

Extending product life – less frequent replacements and repairs

Reducing material waste – optimized fabrication reduces scrap

Using recyclable metals – environmentally friendly materials such as steel and aluminum

This aligns with international buyers’ increasing preference for eco-friendly, cost-efficient industrial solutions.

Used in electrical systems, manufacturing, automation, energy distribution, and commercial/industrial infrastructure.

Yes. OEM and wholesale clients can specify size, material, mounting patterns, and surface finishes.

Yes, enclosures are made from corrosion-resistant and durable materials for demanding industrial environments.

Professional suppliers can handle both low-volume prototypes and high-volume OEM/wholesale production.

To ensure reliable quality, precise dimensions, compliance with standards, and on-time delivery for industrial projects.

Custom industrial metal enclosures are indispensable for industrial and OEM applications, offering protection, precision, and durability. By partnering with experienced manufacturers, B2B buyers benefit from scalable production, strict quality control, and long-term operational efficiency.

High-quality custom enclosures reduce downtime, optimize assembly, and ensure safe operation of critical equipment—making them a smart choice for industrial buyers worldwide.