Precision Hardware Customized Solutions Manufacturer

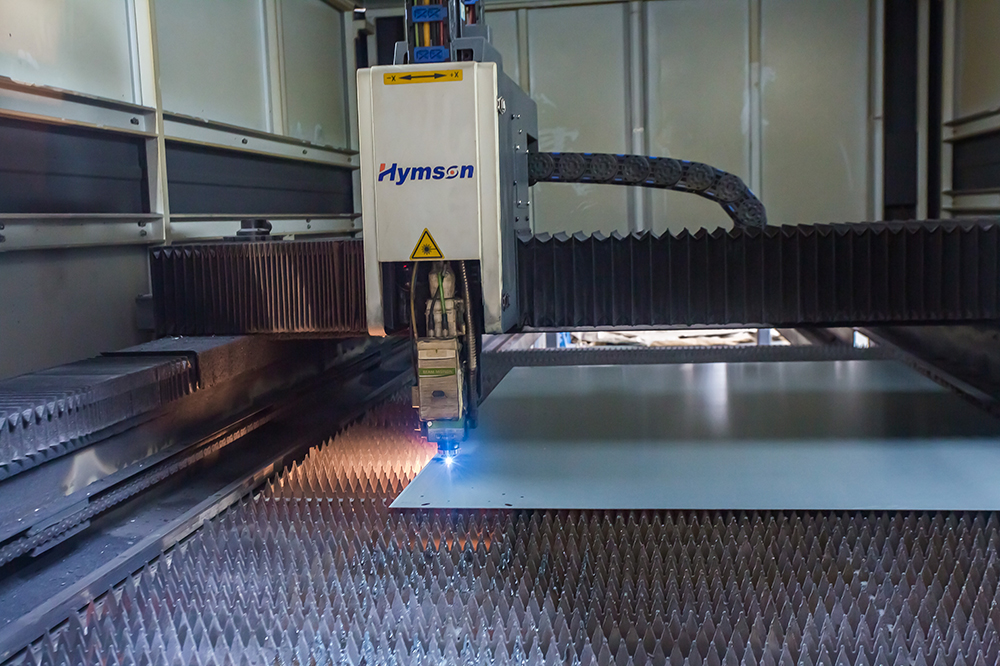

CNC sheet metal cutting is an automated fabrication process where computer-controlled machines cut sheet metal into precise shapes. By following digital designs, CNC systems move cutting tools (like lasers or plasma torches) along pre-programmed paths to slice metal sheets with extreme accuracy. Many modern sheet metal operations rely on CNC lasers or punch presses for precision cuts.

For example, CNC laser cutting can achieve near-mirror smooth edges with tolerances around ±0.1 mm, far beyond what manual tools can match. This level of repeatability and consistency makes CNC cutting fundamental in industries like aerospace, automotive, and electronics where high quality and tight tolerances are essential.

Relevant Standards:

Contents

The CNC sheet metal cutting process typically follows these steps:

Design & Programming: An engineer uses CAD software to create the part design. This digital model is converted into CNC code (G-code) that tells the cutting machine the tool paths and parameters.

Material Setup: A flat metal sheet is secured on the machine’s bed. Common materials include stainless steel, carbon steel, aluminum, copper, and brass.

Nesting: Parts are “nested” on the sheet to minimize waste. Automated nesting software arranges shapes tightly to maximize material usage.

Machine Setup: The machine is set up with the appropriate cutting head (laser, plasma, waterjet, etc.) and cutting gas if needed (oxygen, nitrogen, or compressed air for laser/plasma cutting).

Cutting Operation: The CNC controller moves the cutting head along the programmed path. For example, in laser cutting, a high-power laser melts or vaporizes the metal along a precise line. The cut piece falls away as the laser (or other tool) completes the contour.

Post-Processing: After cutting, parts may require minimal finishing like deburring or cleaning. Modern CNC methods (especially laser cutting) often leave smooth, burr-free edges, reducing the need for extra handwork.

Throughout this process, CNC control ensures each part is cut exactly to the programmed dimensions. Compared to manual cutting, CNC machines are highly repeatable and produce less scrap material. Automation also speeds up production since the same program can run dozens or hundreds of parts with no manual adjustments.

CNC sheet metal cutting uses several main cutting technologies. Each has its strengths and ideal applications:

Laser cutting employs a focused beam of light to cut metal. In modern systems, a fiber or CO₂ laser is guided by CNC to melt or vaporize the metal along the desired shape. Fiber lasers (like Shengwo’s Bystronic 6000W machine) are especially powerful: they can cut thick steels (carbon steel >20 mm, stainless >12 mm) at high speed.

Laser cutters yield very tight tolerances (often ±0.02 mm to ±0.1 mm) and smooth edges. They are versatile too, handling simple geometries as well as intricate patterns with ease. Modern laser systems include features like autofocus, part nesting, and anti-collision controls to boost automation.

Plasma cutters use a high-temperature ionized gas stream (plasma) to slice through conductive metals. CNC plasma cutting handles thicker plates (up to 50 mm or more) faster than lasers and at lower equipment cost. Plasma is ideal for large structural or industrial parts. The cut edge from plasma is good, though typically a bit rougher than laser and may need extra finishing. Plasma machines are less energy-efficient on thin sheets and not as precise as lasers, but they excel in heavy-duty applications.

Waterjet cutters direct an ultra-high-pressure jet of water mixed with abrasive particles to erode the metal. This “cold” cutting method generates no heat-affected zone, so it won’t warp heat-sensitive alloys. Waterjet cutting can cut very thick or exotic materials (even titanium or ceramics), and achieves fine detail.

The edges are smooth and typically require little after-processing. However, waterjets are slower and have higher operating costs (abrasive media), making them best for specialty parts rather than high-volume steel cutting.

Mechanical CNC punch presses and shears physically shear or stamp sheet metal. Punching uses hardened tools to press holes and shapes in one motion, while shearing uses blade edges to cut straight lines. These methods are extremely fast and economical for simple, high-volume parts (e.g. ventilation grilles, brackets). They produce clean edges but can only cut pre-defined shapes with limited complexity. Any curved or intricate detail still requires laser or waterjet cutting.

Each CNC cutting technique has trade-offs, so manufacturers choose based on material, thickness, and part geometry. For example, laser cutting is perfect for thin to medium sheets with complex contours, while plasma suits very thick steel work. The chart below summarizes typical ranges:

| Cutting Method | Precision | Thickness Range | Speed/Cost | Best For |

|---|---|---|---|---|

| Laser (fiber) | Very High (±0.1 mm) | Thin–Moderate (up to ~20 mm steel) | Fast, High Equipment Cost | Electronics, automotive parts with intricate shapes |

| Plasma | Moderate | Moderate–Thick (10–50+ mm) | Very Fast, Lower Cost | Heavy structural and industrial plates |

| Waterjet | High | Thin–Very Thick (no heat limits) | Slow, High Operating Cost | Exotic materials, aerospace/titanium parts requiring no heat distortion |

| Punch/Shear | Good for basic shapes | Thin sheets | Very Fast, Low Cost | Repetitive, simple parts (vent panels, simple enclosures) |

Using CNC sheet metal cutting delivers a range of benefits over traditional cutting:

Precision and Consistency: CNC cutting machines follow digital designs exactly, yielding very tight tolerances. Modern CNC lasers routinely cut within ±0.1 mm accuracy (and specialized systems can hold ±0.02 mm). This precision ensures parts fit and function perfectly in assemblies. Because CNC programs are repeatable, every part in a batch is virtually identical, eliminating human error and ensuring consistent quality.

High Efficiency and Speed: CNC machines can run continuously and at high speed. Once programmed, they start cutting immediately (no custom tooling needed). CNC laser systems can cut sheet metal very quickly – for example, thin 1.2 mm steel can be cut at over 25 meters per minute. Faster cutting reduces production time and per-part cost. Automated nesting and toolpath optimization further minimize idle motion and scrap. According to industry guides, CNC cutting “reduce[s] waste and save[s] time compared to manual processes”.

Energy Efficiency and Low Operating Cost: Especially with fiber lasers, CNC sheet metal cutting is more energy-efficient than older methods. Fiber laser machines convert electrical power to laser light at efficiencies over 30%, compared to ~10% for CO₂ lasers. For example, a 4 kW fiber laser draws only ~13 kW from the mains versus ~40 kW for a CO₂ laser. That efficiency reduces electricity bills and heat load. Additionally, CNC systems minimize material waste through precise nesting. Over long runs, these efficiencies save significant cost and make cutting operations greener.

Intelligent Automation: Modern CNC sheet cutting systems include smart features like automatic nesting, autofocus, and collision avoidance. The machine can adjust parameters on the fly (e.g. laser focus and speed based on material thickness) and monitor its own performance. Such automation reduces the need for constant operator intervention. For example, Shengwo’s Bystronic 6000W fiber laser supports automatic nesting and collision protection to maximize material use and safety. Advanced CNC controllers also allow quick job changes: feeding a new CAD file automatically reprograms the cut paths, enabling rapid changeovers for prototyping or mixed-batch production.

Versatility: CNC cutting handles a wide variety of metals and geometries. By simply loading a new program, the same machine can switch from cutting stainless steel to aluminum or copper. Specialized machines (like 3D laser cutters) can even bevel cuts or cut non-metal materials. Because CNC cuts rely on software patterns, they can produce intricate shapes and complex perforations (e.g. custom architectural panels or decorative screens) without extra effort. This flexibility means one CNC shop can meet diverse manufacturing needs, from thin electrostatic panels to thick chassis components.

Accuracy & Quality: Tighter tolerances, smoother edges

Speed & Productivity: Fast cutting speeds, quick setup (no special dies)

Consistency: Identical parts with minimal scrap

Energy & Cost Efficiency: Lower power use (fiber lasers) and less rework

Automation: Smart CNC controls reduce labor, support 24/7 production

Material Flexibility: Cuts steel, aluminum, brass, titanium, etc., in thin or thick gauges

Zhuhai Shengwo Machinery Technology Co., Ltd. is a precision sheet metal supplier with advanced CNC cutting capabilities. Shengwo’s facility is equipped with state-of-the-art CNC machinery, including fiber lasers and combo laser-punch systems, to handle a broad range of projects from prototypes to large batches.

Notably, Shengwo has integrated Swiss Bystronic fiber laser technology into its processes. The Bystronic 6000W fiber laser in Shengwo’s shop offers exceptional cutting power. This 6 kW laser “can efficiently cut a variety of metal materials such as stainless steel, carbon steel, aluminum, copper, etc.” – especially thick plates (carbon steel up to 20 mm, stainless up to 12 mm) – with high speed and deep penetration.

In use, the Bystronic system achieves a cutting repeat-position accuracy of ±0.02 mm thanks to its precision CNC control and high-end servo motors. The result is ultra-smooth edges and minimal part distortion even on complex shapes.

Shengwo also uses hybrid machines like the Trumpf TruMatic 3000 (3 kW fiber laser plus turret punch), enabling seamless switching between laser cutting and punch in one setup. This flexibility lets Shengwo produce intricate geometries (via laser) and standardized holes/forms (via punching) without multiple machine changes.

In all their laser cutting equipment, advanced features such as autofocus, intelligent nesting, and anti-collision controls are standard. These automated functions boost material yield and operator safety, reflecting Shengwo’s focus on Industry 4.0 manufacturing.

In terms of precision, Shengwo advertises the ability to hold tolerances of ±0.05 mm on laser-cut parts. The company highlights its “advanced laser technology” producing smooth, burr-free edges and “intricate patterns” even for demanding applications like medical device hypotubes. The combination of high-power lasers and experienced programmers means Shengwo can fabricate highly detailed sheet metal components consistently.

Choosing a sheet metal partner depends on quality, technology, and service. Shengwo stands out in several ways:

High Quality at Competitive Cost: Shengwo emphasizes “excellent quality without exceeding the budget”. They optimize production to lower costs and pass savings to customers. Materials and workmanship meet strict standards, ensuring parts function reliably in end products.

Advanced Technology: With over 20 CNC machines (laser cutters, punch presses, bending and welding equipment), Shengwo can handle projects of various scales. Their investment in top-tier equipment (Bystronic lasers, Trumpf systems, Zeiss metrology) keeps them at the cutting edge of sheet metal fabrication. Combined with a 20+ member tech team offering design-for-manufacturing (DFM) support, Shengwo helps clients refine part designs for efficiency.

Comprehensive Service: From quoting to delivery, Shengwo provides full support. The firm commits to fast responses (24h to quote) and flexible capacity (samples in 3 days, annual output 200k+ pcs). They offer material selection advice and thorough process inspections (using precise gauges and controls) to meet specs. Customer testimonials note reliable on-time delivery and quick issue resolution.

Experienced Team: With over a decade in precision metal processing and around 60 specialized employees, Shengwo’s staff are experts in both production and customer care. About 70% of their team are technical talent (engineers, programmers, QA). This depth of experience is a big advantage for complex or critical projects, where knowledgeable feedback and process control make a difference.

Flexibility: Whether it’s a quick prototype or a large production run, Shengwo tailors its operations. Their mix of capabilities means they can easily switch between small batches and high-volume jobs. Customers can benefit from bundled services: Shengwo can cut, bend, weld, coat, and finish metal parts all under one roof, streamlining supply chains and accountability.

In summary, Shengwo pairs advanced CNC technology with responsive service. Their adoption of Swiss fiber lasers and intelligent automation aligns with the high precision and efficiency goals of China manufacturers. By choosing Shengwo, clients gain a partner committed to quality parts on time, every time.

Ready to optimize your sheet metal fabrication? Shengwo’s CNC experts are standing by to handle your designs with precision cutting technology. Contact Shengwo today to discuss your requirements and get a free quote. Our team will work with you on material selection, part design (DFM), and schedule to ensure your project’s success. Experience the efficiency and accuracy of CNC sheet metal cutting with a trusted supplier – from concept to finished part, Shengwo delivers.

Q1: What does CNC mean in sheet metal cutting?

CNC stands for Computer Numerical Control. In sheet metal cutting, it means using computer-driven machines (lasers, plasma cutters, etc.) to follow programmed cutting paths. This replaces manual guides or templates. CNC ensures each part matches the digital design exactly.

Q2: How is CNC sheet metal cutting different from manual cutting?

CNC cutting is automated and much more precise. Because the machine follows exact coordinates, every cut part is consistent. CNC also runs faster and wastes less metal. For example, a CNC laser cutter can make hundreds of cuts at high speed without operator fatigue, whereas manual cutting is slower and less accurate.

Q3: What materials can be cut with CNC sheet metal cutting?

A wide range: stainless steel, carbon steel, aluminum, copper, brass, titanium, and more. The choice of cutting method (laser, plasma, waterjet) depends on material type and thickness. For instance, lasers excel on mild and stainless steel up to ~20 mm, and also cut aluminum; waterjets handle thicker or heat-sensitive materials; plasma works well on very thick steel.

Q4: How precise is CNC sheet metal cutting?

Very precise – often within a few hundredths of a millimeter. High-end CNC lasers can hold ±0.02–0.1 mm tolerances. This precision allows tight-fitting parts and fine details. By contrast, manual or mechanical cutting without CNC typically has looser tolerances and rougher edges.

Q5: What are the benefits of using CNC sheet metal cutting services?

Key benefits are accuracy, speed, and consistency. CNC produces smooth cuts with minimal burrs, reducing finishing work. It also speeds up production since no custom tools are needed – simply upload your design and the machine cuts automatically. CNC cutting is highly repeatable, meaning batch after batch of parts are identical. The process is also more cost-effective in the long run due to lower waste and energy use (especially with fiber lasers).