Precision Hardware Customized Solutions Manufacturer

Author | Shengwo Industry Insights Team

Updated | November 2025

Contents

Air damper manufacturers play an important role in HVAC safety and air-flow systems. Choosing the right partner ensures product stability and long-term performance.

Professional Air Damper manufacturers not only supply standard products but also provide customized engineering solutions for harsh industrial environments. The best manufacturers understand airflow requirements, fire-safety regulations, application design, and installation challenges in real-world conditions. Their engineering decisions directly impact energy efficiency, operational cost, and the environmental impact of large commercial facilities. When selecting a supplier, a company must consider quality systems, factory capability, delivery speed, material standards, and after-sales support, not only the price.

Quality is the foundation of airflow security and mechanical durability. For critical HVAC environments, poorly manufactured air dampers can lead to system failure, temperature imbalance, or severe fire-risk exposure.

Reliable Air Damper manufacturers follow strict quality systems that ensure consistent performance of every part, whether used in computer rooms, factories, or high-risk industrial facilities. A high-quality air damper regulates airflow efficiently while reducing turbulence and noise. Manufacturers must use precise cutting, bending, and assembly processes to maintain dimensional accuracy, structural stability, and sealing integrity. Quality also affects product lifespan, reducing maintenance costs and minimizing downtime risks in large-scale HVAC installations.

Choosing Air Damper manufacturers with strong production capabilities is crucial for long-term success in engineering projects.

Manufacturers with advanced facilities can quickly adapt to different customer needs, including complex HVAC solutions and customized airflow damper geometries. Their engineering ability includes material selection, mechanical performance evaluation, and safety compliance verification. The more complete their factory capability, the better they can support both small and large batch orders while maintaining product consistency and predictable lead time.

The material processing stage directly affects the strength and safety of the final air damper.

Leading Air Damper manufacturers rely on galvanized sheet metals processed through laser cutting, CNC bending, welding, riveting, and industrial-standard assembly. Each process step must control tolerances tightly, ensuring blades can move smoothly and seal properly. High-precision metal machining minimizes deformation, improves corrosion resistance, and ensures structural stability for both mechanical and fire-rated dampers. The more accurate the process, the higher the system reliability.

Trusted Air Damper manufacturers must adopt strict testing standards, fire-protection regulations, and air-passing certifications.

This includes airflow resistance testing, sealing performance evaluation, leakage class verification, material oxidation resistance analysis, and blade torque measurements. Professional manufacturers maintain formal audit records, traceability systems, and long-term testing data. As a result, customers receive guaranteed reliability, stable performance, and predictable lifetime performance under continuous airflow pressure and heat exposure.

Evaluating whether an Air Damper manufacturer is reliable requires observing multiple core indicators beyond pricing.

Engineering competence, factory scale, industrial compliance, operational transparency, and detail-level quality assurance are all crucial. A reliable partner considers project requirements from a technical perspective, not just commercial perspective, ensuring the system works flawlessly after installation. Manufacturers must be capable of providing technical drawings, sample validation, installation guidance, assembly documentation, and continuous optimization support during production and after delivery.

Production capacity directly influences manufacturing stability, cost structure, and supply chain reliability.

The best professional Air Damper manufacturers own advanced factories with efficient equipment layouts and end-to-end fabrication capability. Larger facilities allow more complex product structures, tighter project schedules, and scalable production for enterprise-level customers. Process automation, upgraded equipment, and layout optimization significantly reduce energy waste, improve accuracy, and support higher standards of product repeatability.

Cost transparency is crucial when comparing different Air Damper manufacturers and planning large-scale HVAC projects. Transparent pricing allows clients to predict total investment cost, avoid unexpected surcharges, and evaluate return on investment.

Professional Air Damper manufacturers should provide structured quotations, material breakdowns, and clear lead time commitments. High-quality suppliers also help customers reduce cost in design optimization, material utilization planning, and engineering adjustments without sacrificing safety or function. Long-term cost efficiency comes from reliability, fewer maintenance needs, and a stable supply chain, not simply cheap product pricing. True value is measured by product durability, predictable manufacturing cycles, and reduced operational risk.

Timely delivery reflects how capable a manufacturer is at managing production risks and supplier coordination. In time-sensitive HVAC projects, delays can lead to installation issues or significant cost overruns.

Reliable Air Damper manufacturers must demonstrate efficient internal coordination, scheduling flexibility, and a structured supply management framework. This ensures the on-time delivery of standard dampers, custom configurations, and bulk orders. A manufacturer that reacts quickly to engineering changes, design updates, and urgent requests supports business continuity and maintains customer trust. Fast response speed is a strong indicator of a supplier’s professionalism and operational maturity.

As one of the emerging Air Damper manufacturers serving industrial HVAC clients worldwide, Shengwo delivers a high standard of manufacturing capability, engineering support, product quality, and supply reliability.

Our facility has expanded 100% to 2,500 sqm, integrating laser cutting, CNC bending, structural assembly, and inspection under one roof. We are an officially audited green supplier for Schneider Electric and hold ISO9001 & ISO14001 certifications from a UK accreditation body. As a National High-Tech Enterprise, we manage production with ERP systems to ensure traceability and standardized execution. Our core operating objectives include safety, quality, delivery, cost control, and innovation.

Shengwo Competitive Strengths Include:

Excellent Delivery Performance: shorter standard lead times, faster engineering response

Excellent Quality: strict manufacturing control & traceable quality system

Cost Competitiveness: optimized production + supply chain strategy

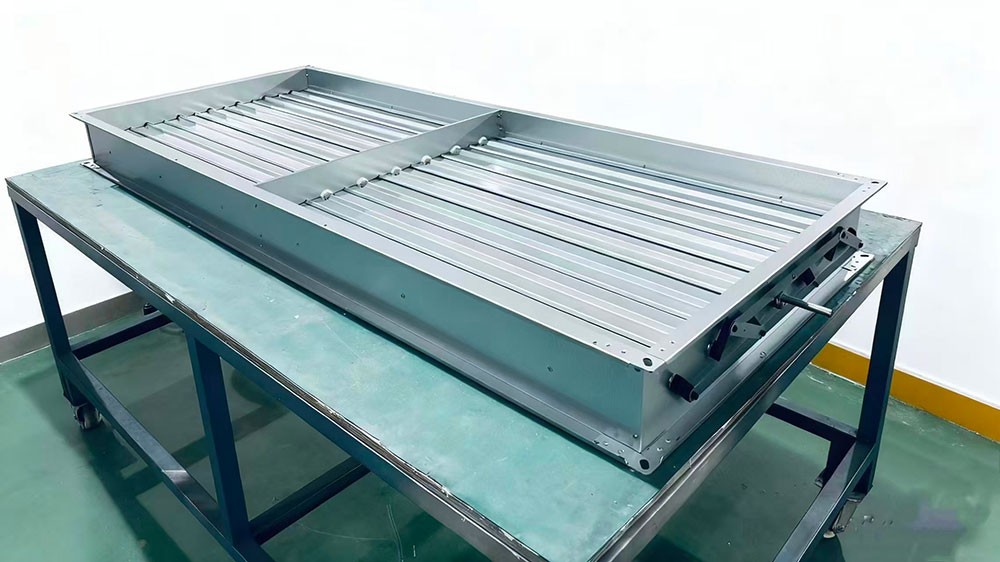

We produce Air Dampers used in large industrial air-conditioning protections, machine rooms, and fire-isolation applications, following processes such as laser cutting, CNC bending, assembling, sealing, and performance testing.

Q1: What industries depend most on professional Air Damper manufacturers?

Industries such as data centers, commercial buildings, manufacturing factories, hospitals, and energy facilities rely heavily on high-standard Air Damper manufacturers. These facilities require accurate air control, fire-protection compliance, and long-term safety assurance. Choosing a qualified supplier ensures performance and regulatory compliance while reducing maintenance costs and operational risk.

Q2: How do Air Damper manufacturers guarantee safety compliance?

Qualified Air Damper manufacturers follow fire-safe design standards, airflow compliance certifications, mechanical load testing, and seal-leak performance verification. They document quality checkpoints, maintain traceability systems, and conduct continuous life-cycle testing to ensure products meet strict engineering requirements.

Q3: Can Air Damper manufacturers provide customized products?

Yes. Leading Air Damper manufacturers can provide customized blade sizes, casing thicknesses, air-pressure ratings, assembly configurations, and special structural requirements. They also support engineering consultation, prototype production, and batch manufacturing to ensure the product matches the installation environment perfectly.

Q4: How do I compare different Air Damper manufacturers effectively?

Compare based on factory capabilities, international certifications, delivery stability, engineering knowledge, project references, and responsiveness. Pricing should not be the only deciding factor—reliability and long-term value matter far more.

Selecting the right Air Damper manufacturers is crucial for long-term HVAC system safety, airflow regulation, and project reliability. An experienced manufacturer ensures product quality, fire protection compliance, and predictable delivery performance.

A truly reliable supplier will invest in engineering capability, supply chain management, technical stability, and continuous improvement. With the proper partner, project risk decreases significantly while operational efficiency improves over time.

If you are seeking reliable Air Damper manufacturers capable of supporting industrial-grade airflow projects, contact shengwo today. Our engineering team will help you evaluate requirements, optimize structure, and accelerate your project delivery with confidence and professionalism.