Precision Hardware Customized Solutions Manufacturer

Contents

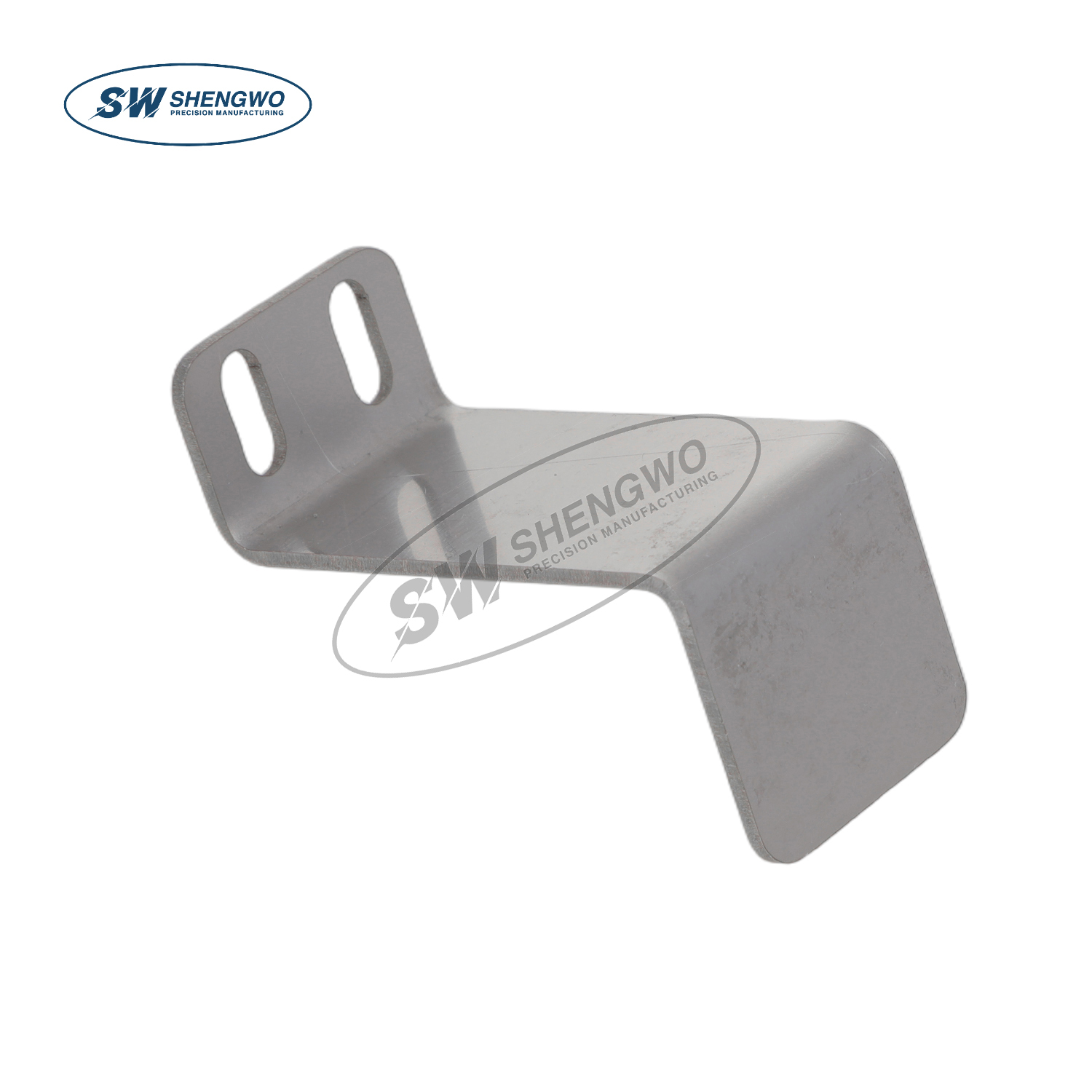

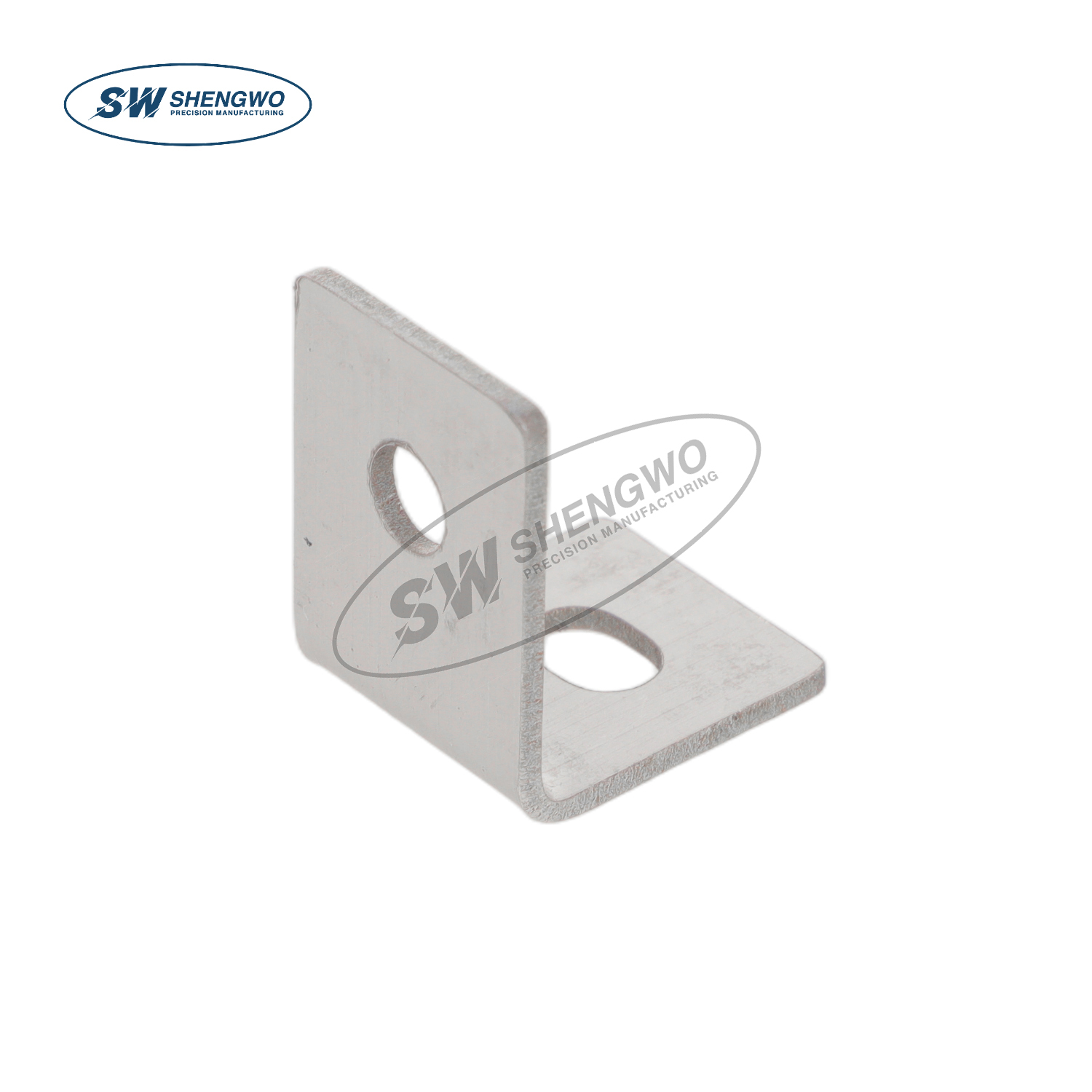

Custom sheet metal manufacturing is an essential solution for industries that require precise, durable, and application-specific metal components. Unlike standard off-the-shelf products, custom manufacturing allows industrial buyers to tailor metal parts to exact functional, structural, and environmental requirements.

For OEM brands, distributors, and project contractors, customized metal production ensures compatibility, long-term reliability, and efficient integration into complex systems.

Custom sheet metal manufacturing refers to the production of metal parts and assemblies based on specific drawings, technical specifications, and application needs. This approach focuses on flexibility, accuracy, and consistency across production batches.

Through controlled manufacturing processes, custom metal components can be produced for both low-volume projects and large-scale industrial supply.

Material selection plays a critical role in the performance and lifespan of industrial metal products. Common materials used in custom manufacturing include:

Stainless steel for corrosion resistance and hygiene requirements

Cold-rolled steel for structural strength

Galvanized steel for electrical and outdoor applications

Aluminum for lightweight and thermal performance

Each material is selected based on operating environment, load conditions, and industry standards.

Professional custom sheet metal manufacturing relies on advanced equipment and experienced engineering support to ensure accuracy and repeatability.

Core production processes typically include:

CNC laser cutting for precise profiles

CNC bending for complex geometries

Welding and mechanical assembly

Surface finishing such as powder coating or plating

These capabilities allow manufacturers to deliver stable quality across diverse industrial applications.

Custom metal manufacturing supports a wide range of industrial products, including:

Electrical enclosures and control cabinets

Industrial storage cabinets and housings

Equipment frames and structural components

Metal racks and support systems

Specialized OEM metal assemblies

Each product is designed to meet specific functional and installation requirements.

For global B2B buyers, consistency and scalability are key considerations. A reliable custom sheet metal manufacturing partner provides:

OEM customization based on technical drawings

Support for bulk and wholesale orders

Stable lead times for long-term cooperation

Engineering assistance during product development

This manufacturing model reduces supply risk while supporting business growth in international markets.

Maintaining consistent quality is essential in industrial metal manufacturing. Professional manufacturers implement strict quality control systems throughout the production cycle.

Typical quality control measures include:

Incoming raw material inspection

Dimensional and tolerance verification

Welding and assembly checks

Final inspection before packaging

These processes ensure that custom metal components meet industrial and export standards.

Custom metal components are widely used in:

Manufacturing and automation equipment

Electrical and energy systems

Warehousing and logistics infrastructure

Machinery and industrial tools

Commercial and industrial installations

The flexibility of custom sheet metal manufacturing makes it suitable for a wide range of industrial sectors.

Custom-manufactured metal components contribute to sustainability by offering long service life and recyclability. Durable designs reduce replacement frequency and maintenance costs.

Efficient production planning also minimizes material waste, supporting environmentally responsible manufacturing practices.

It is the process of producing metal parts and assemblies based on specific customer requirements, drawings, and applications.

Yes. Professional manufacturers provide OEM customization, engineering support, and scalable production for brand owners and distributors.

Custom manufacturing can support both low-volume projects and high-volume wholesale production.

Industries include manufacturing, electrical systems, logistics, automation, and industrial infrastructure.

Custom sheet metal manufacturing provides industrial buyers with flexible, precise, and reliable metal solutions tailored to specific applications. By combining advanced production capabilities with strict quality control, manufacturers support OEM and wholesale customers with consistent quality and scalable supply.

Choosing an experienced manufacturing partner ensures long-term performance, cost efficiency, and dependable delivery for global industrial projects.