Precision Hardware Customized Solutions Manufacturer

Contents

As the holiday season approaches, Shengwo Machinery extends our warmest wishes to all our partners, customers, and collaborators around the world. Christmas is a time to celebrate relationships, achievements, and shared trust. Over the past year, Shengwo Machinery has continued to deliver high-quality industrial solutions, specializing in HVAC air dampers, industrial shelving systems, and custom sheet metal fabrication, designed to meet the evolving needs of commercial and industrial clients.

Our dedication to precision, quality, and reliability ensures that each project is executed efficiently and meets international standards. Whether it is providing OEM sheet metal solutions or delivering complete industrial installations, Shengwo Machinery remains committed to excellence. In this blog, we will share insights into our core products, manufacturing processes, and our approach to global partnerships.

For more details on our services, visit our HVAC air dampers page or explore our sheet metal fabrication services.

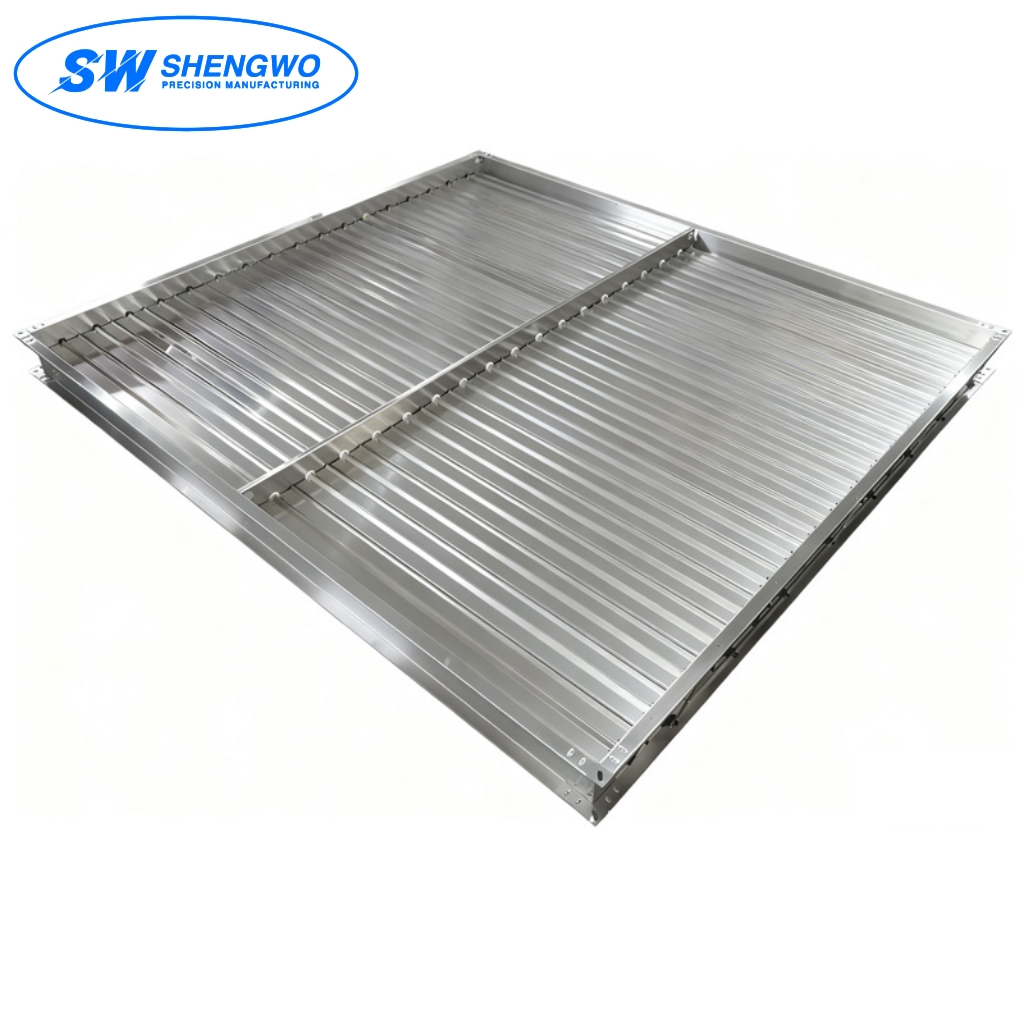

HVAC air dampers are critical components in commercial and industrial heating, ventilation, and air conditioning systems. They control airflow, regulate temperature, and provide essential safety functions, such as fire prevention and isolation. At Shengwo Machinery, we focus on delivering precision-engineered air dampers that combine durability, efficiency, and safety.

Fire protection: Our air dampers are designed to prevent the spread of fire and smoke, enhancing the safety of commercial and industrial facilities.

Durability: Made from high-quality materials, these dampers withstand long-term operational stress.

Precision engineering: CNC cutting and bending ensure consistent dimensions and fitment for any HVAC system.

Easy integration: Compatible with existing HVAC installations, reducing installation time and cost.

The production of HVAC air dampers at Shengwo Machinery follows strict quality control measures:

Laser cutting: Provides high precision and clean edges for sheet metal components.

CNC bending: Ensures structural integrity and consistent dimensions.

Assembly: Conducted by skilled teams according to standardized work instructions (SOPs), including diagonal alignment checks and careful rivet assembly.

For more details, visit our HVAC air dampers product page.

Industrial storage and shelving solutions are essential for efficient warehouse and facility management. Shengwo Machinery provides modular, high-strength industrial shelving systems that cater to diverse storage needs.

High load capacity: Engineered to hold heavy industrial materials and products safely.

Durable construction: Galvanized steel and powder coating protect against corrosion and wear.

Customizable design: Adjustable racks, modular assembly, and tailored dimensions to meet client-specific requirements.

Ease of assembly: Our shelving systems are designed for straightforward installation, reducing setup time.

Warehouses and distribution centers

Manufacturing and assembly facilities

Commercial storage solutions

Retail backrooms

Shengwo’s shelving systems are designed to maximize storage efficiency and operational safety. Learn more on our industrial shelving solutions page.

Our custom sheet metal fabrication services cater to industrial and commercial clients who require bespoke solutions. Shengwo Machinery specializes in OEM sheet metal solutions, providing flexible, high-quality production to meet client specifications.

CNC cutting: Achieves precise dimensions with minimal waste.

CNC bending: Ensures accurate angles and structural integrity.

Welding and assembly: Skilled operators assemble parts with attention to quality and durability.

Surface finishing: Powder coating, galvanization, or custom treatments for corrosion resistance and aesthetic requirements.

Tailored to specific industrial applications, such as HVAC, electrical enclosures, and storage solutions.

High repeatability ensures consistent quality for large-scale projects.

Flexible production allows fast turnaround times.

Visit our sheet metal fabrication services to explore custom options.

Shengwo Machinery’s commitment to precision manufacturing goes beyond equipment. Our assembly teams follow standardized work instructions, ensuring consistency and efficiency.

Air damper assembly: Follow SOPs, step-by-step assembly, diagonal checks, rivet assembly without rivet guns. Teams guided by engineers achieve 300% efficiency improvements.

Cable reel assembly: Galvanized metal components, plastic parts, and guide rails assembled into finished products according to client specifications.

Each product undergoes rigorous inspection, including dimensional checks and functional testing.

Standardized procedures reduce defects and improve reliability.

Through these processes, we maintain high standards for all HVAC air dampers, industrial shelving systems, and sheet metal products.

Shengwo Machinery’s success is built on strong relationships with clients around the world. We collaborate with businesses across multiple industries, delivering reliable industrial solutions with a focus on quality and customer satisfaction.

Tailored solutions for individual project needs

Responsive communication and technical support

Commitment to delivering on time and within budget

Our global partners trust Shengwo Machinery for precision-engineered HVAC air dampers, industrial shelving systems, and custom sheet metal fabrication.

This Christmas, we celebrate the festive season and the trust we have earned from our customers worldwide.

🎁 Thank you for choosing Shengwo Machinery as your manufacturing partner.

✨ We look forward to supporting your projects with precision, quality, and reliability in the coming year.

For more information on our products and services, visit our website:

🌐 Shengwo Machinery Official Website

Merry Christmas & Happy New Year!