Precision Hardware Customized Solutions Manufacturer

Author | Shengwo Industry Insights Team

Updated | October 2025

Contents

Professional Sheet Metal Fabrication plays a vital role in nearly every modern industry — from automotive and construction to aerospace, electronics, and renewable energy. Manufacturers depend on precision sheet metal parts to ensure performance, efficiency, and reliability in their final products.

Selecting a professional sheet metal fabrication manufacturer is not simply about finding the lowest cost — it’s about choosing a partner with advanced technology, strict quality control, and engineering excellence. According to the Fabricators & Manufacturers Association International (FMA), the global fabrication industry continues to evolve rapidly with automation, AI integration, and sustainability standards.

In this article, we’ll outline the top 10 qualities every business should consider before partnering with a Professional Sheet Metal Fabrication manufacturer, and why Shengwo Machinery is your trusted supplier in China.

Experience is the foundation of quality fabrication. A manufacturer with decades of experience has mastered handling diverse metals like stainless steel, aluminum, and carbon steel, each requiring distinct bending, welding, and surface finishing techniques.

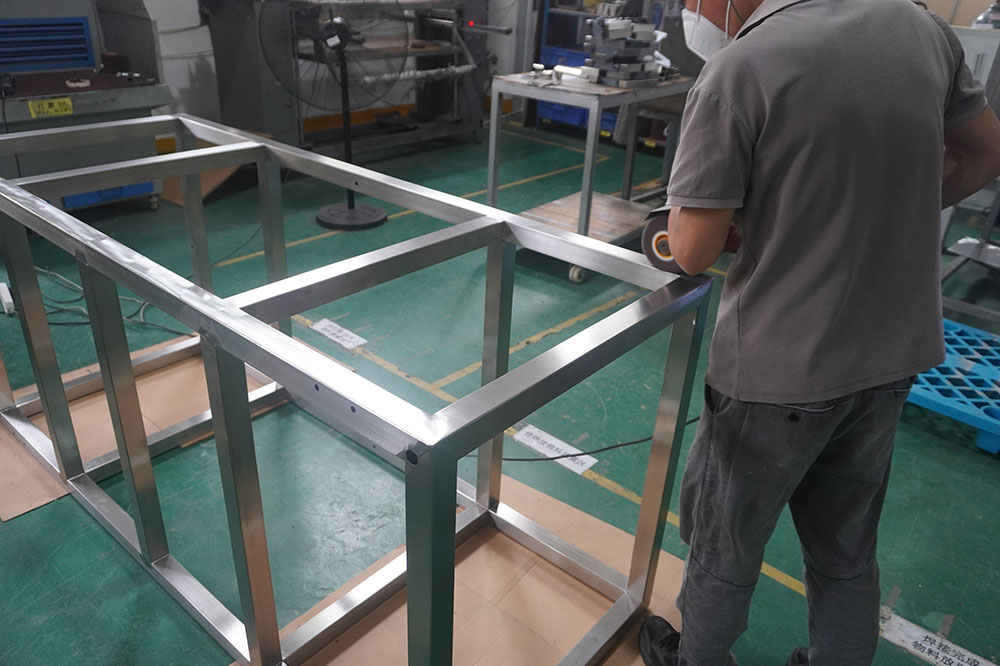

An experienced Professional Sheet Metal Fabrication company understands complex tolerances and can efficiently transform raw materials into high-precision components. Shengwo Machinery, with years of engineering experience, ensures consistency from prototype to large-scale production.

To assess a company’s expertise, review their project portfolio and certifications such as AWS welding standards (American Welding Society). These credentials indicate that a manufacturer operates with professionalism, safety, and precision.

Modern fabrication relies heavily on high-tech machinery. Companies equipped with advanced tools deliver faster production, better accuracy, and reduced material waste. Essential equipment includes laser cutting systems, CNC press brakes, turret punches, robotic welding stations, and automated powder coating lines.

Shengwo Machinery continuously upgrades its equipment to align with the latest industry standards. Our CNC and fiber laser cutting systems can handle complex geometries with tight tolerances — ensuring a clean edge and perfect fit every time.

Industry experts from Fabricating & Metalworking Magazine emphasize that automation and laser precision are key differentiators for modern sheet metal fabrication, helping clients achieve repeatable and cost-effective results.

One hallmark of Professional Sheet Metal Fabrication is customization. No two clients have identical requirements, and a reliable manufacturer must offer design flexibility and tailor-made fabrication solutions.

At Shengwo, our engineering team works directly from client-provided CAD drawings, 3D models, or even conceptual sketches. We optimize each design for manufacturability — adjusting dimensions, bending radii, and weld seams to improve efficiency and reduce costs.

This approach ensures that the final product not only matches the client’s vision but also performs optimally in real-world applications. According to ThomasNet, companies offering full design-to-fabrication support enjoy higher client retention and faster product development cycles.

High-quality fabrication begins with strict quality control systems. Professional manufacturers maintain traceability, inspection checkpoints, and adherence to international standards like ISO 9001 (ISO Official Site).

At Shengwo, quality control is embedded in every stage — from raw material inspection to final packaging. Our QC team performs CMM measurements, weld strength tests, coating thickness verification, and visual inspections to ensure defect-free products.

By following ISO and AWS guidelines, Shengwo guarantees that every component meets or exceeds customer requirements. Investing in certified manufacturers means reducing risk, rework, and unexpected downtime in your projects.

A reliable Professional Sheet Metal Fabrication partner should offer end-to-end solutions. Instead of relying on multiple vendors, choosing a full-service provider saves time and improves quality consistency.

Shengwo Machinery provides a complete fabrication pipeline:

Laser Cutting & CNC Punching

Bending & Forming

Welding (MIG/TIG/Spot)

Surface Finishing: Powder Coating, Polishing, Galvanizing

Assembly & Packaging

This integrated workflow minimizes transportation time and ensures that all processes meet the same precision standard. According to The Fabricator, consolidating fabrication under one roof reduces production lead times by up to 30%.

Strong communication is the backbone of successful long-term partnerships. A professional manufacturer must understand your technical specifications and respond promptly to inquiries.

At Shengwo, our bilingual project management team bridges the gap between engineering and production. We provide detailed DFM (Design for Manufacturing) feedback, progress updates, and transparent pricing breakdowns to keep clients informed.

Clear communication ensures fewer revisions, reduced errors, and faster delivery — all key attributes of a Professional Sheet Metal Fabrication manufacturer. According to Harvard Business Review, transparent supplier communication can increase customer satisfaction by up to 40%.

While price is always important, quality remains the priority. Shengwo implements lean manufacturing principles to optimize production efficiency, minimize waste, and deliver competitive pricing without compromising durability or aesthetics.

We balance cost-effectiveness through material optimization, efficient machine scheduling, and digital inventory tracking. This ensures clients get the best value for every dollar spent.

Reliable Professional Sheet Metal Fabrication companies should provide transparent quotations, itemized costs, and consistent quality assurance — allowing clients to make informed decisions without hidden expenses.

On-time delivery reflects professionalism. Delayed shipments can disrupt entire production chains, causing financial losses and client dissatisfaction. Shengwo maintains strict scheduling systems and works with reliable logistics partners to ensure prompt global delivery.

We use digital ERP tracking to monitor fabrication progress in real-time, ensuring that every order meets its timeline. For large-scale projects,Shengwo coordinates multiple production lines to maintain supply chain stability.

According to Supply Chain Quarterly, 92% of B2B buyers value on-time delivery as the most important factor in supplier selection. Shengwo’s commitment ensures that your operations never face costly downtime.

A company’s reputation reflects its reliability. Before choosing a Professional Sheet Metal Fabrication partner, always review testimonials, case studies, and client feedback.

Shengwo has built long-term relationships with global clients in industries such as telecommunication, industrial automation, retail equipment, and renewable energy. Many of our clients return for repeat orders because of our consistent performance and transparent communication.

Industry directories like MFG.com and ThomasNet showcase Shengwo’s profile and highlight our proven track record as a trusted metal fabrication manufacturer in China.

The future of Professional Sheet Metal Fabrication depends on innovation and sustainability. Modern manufacturers are adopting AI-powered production systems, IoT-based monitoring, and eco-friendly coatings to reduce environmental impact.

Shengwo leads the way by investing in green manufacturing technologies, such as energy-efficient laser systems and waste recycling programs. We continuously research new methods to reduce CO₂ emissions while maintaining top-tier precision.

Sustainability is not just a trend—it’s an obligation. As highlighted by GreenBiz, environmentally responsible suppliers gain more trust from international buyers seeking long-term partnerships.

Shengwo Machinery is more than a supplier — we are your strategic manufacturing partner. With expertise in sheet metal fabrication, CNC precision machining, and custom display rack production, we transform your technical drawings into high-performance products.

Our strengths include:

Over a decade of fabrication expertise

Advanced CNC and laser technologies

Strict ISO-certified quality management

Customized production based on client drawings

Fast prototyping and bulk production capacity

Shengwo provides global clients with end-to-end fabrication solutions, ensuring every component achieves international quality standards while maintaining cost efficiency.

Q1: What industries benefit most from Professional Sheet Metal Fabrication?

A1: Industries such as aerospace, automotive, construction, and energy all depend on precision metal fabrication for their infrastructure and components.

Q2: Can Shengwo handle OEM/ODM projects?

A2: Yes. Shengwo offers complete OEM/ODM fabrication solutions, customizing materials, finishes, and packaging per client requirements.

Q3: What file formats does Shengwo accept for custom fabrication?

A3: We accept DWG, DXF, STEP, and SolidWorks files for maximum compatibility.

Q4: How does Shengwo ensure quality consistency?

A4: Each part undergoes multi-stage inspection and testing following ISO 9001 and AWS welding standards.

Q5: What’s Shengwo’s average lead time for production?

A5: Depending on complexity, standard projects take 2–4 weeks from order confirmation to delivery.

Choosing the right Professional Sheet Metal Fabrication manufacturer determines your product’s success and brand reputation. Look for expertise, modern technology, quality assurance, and a proven track record of delivering results.

At Shengwo Machinery, we combine advanced manufacturing, strict quality control, and engineering innovation to deliver world-class fabrication solutions that exceed expectations.

👉 Contact Shengwo today to discuss your next sheet metal fabrication project — where precision meets perfection, and your ideas are brought to life.