Precision Hardware Customized Solutions Manufacturer

Author | Shengwo Industry Insights Team

Updated | September 2025

Contents

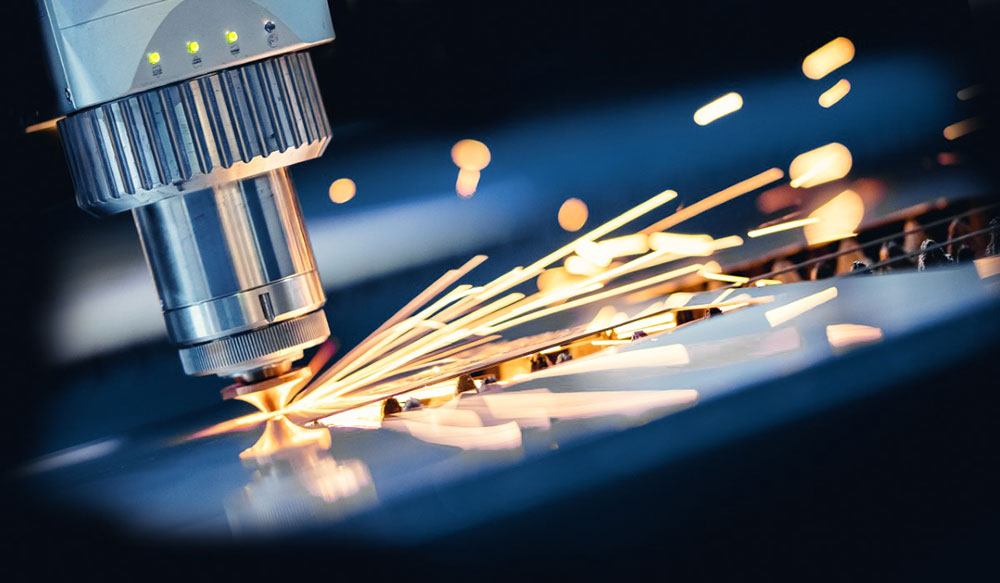

Metal Laser Cutting has rapidly become one of the most critical processes in modern metal fabrication. In 2025, industries ranging from automotive to aerospace, electronics to construction, all rely on this advanced technology to achieve speed, precision, and cost efficiency. Unlike traditional cutting methods, Metal Laser Cutting uses a concentrated laser beam to melt and vaporize metal with extreme accuracy, producing smooth edges and minimal material waste.According to the Laser Institute of America,demand for laser cutting is growing steadily as companies seek efficiency and sustainability in production.

For B2B buyers, understanding what Metal Laser Cutting is, how it works, and how to select the right manufacturing partner is essential to staying competitive. Global supply chains are evolving toward smarter and greener production, and businesses need to align with suppliers who can deliver not only precision but also innovation.

At its core, Metal Laser Cutting is a subtractive manufacturing process where a high-powered laser beam is directed at a metal sheet or component, cutting it with heat and energy instead of physical contact. The process involves three key elements:

Laser Source: Typically fiber lasers or CO₂ lasers generate a high-intensity beam.

Optics and CNC Controls: The beam is focused through lenses and guided by advanced computer-controlled systems.

Assist Gases: Oxygen, nitrogen, or compressed air is used to blow molten metal away from the cut, improving quality and speed.

The process is fully digital, meaning that CAD files can be uploaded directly into CNC systems. The machine follows the programmed path with high precision, cutting even the most intricate geometries. This eliminates tooling costs, reduces setup time, and ensures consistency across large production runs.

In 2025, advanced laser cutters also include real-time monitoring systems, where sensors detect material thickness, adjust laser intensity, and optimize gas flow automatically. This makes Metal Laser Cutting not only precise but also highly adaptive to different projects.

👉 Related: CNC Machining Services

For industrial buyers, Metal Laser Cutting provides a set of advantages that directly impact cost, efficiency, and product quality:

Unmatched Precision – Achieving tolerances as fine as ±0.05mm, making it ideal for industries like aerospace and medical devices.

Design Flexibility – Capable of producing sharp corners, micro-perforations, and complex curves that traditional methods cannot replicate.

High Productivity – Faster cutting speeds mean more parts produced in less time, reducing lead times for urgent projects.

Reduced Waste – Optimized nesting software ensures efficient use of raw materials, lowering material costs.

Minimal Post-Processing – Smooth edges and clean cuts reduce the need for additional grinding or finishing.

Automation-Friendly – Easily integrated into robotic systems, allowing continuous, unattended production.

In addition, AI-driven cutting algorithms now optimize energy usage, tool paths, and beam power. This not only improves throughput but also reduces carbon footprint—an increasingly important factor for B2B buyers prioritizing sustainable supply chains.

👉 Related: Sheet Metal Fabrication Process

The versatility of Metal Laser Cutting means it is applied across nearly every manufacturing sector. Common applications include:

Automotive: Cutting brackets, engine components, and exhaust parts with high consistency.

Aerospace: Producing lightweight and strong components that meet strict certification standards.

Construction: Creating structural steel elements, decorative panels, and façade designs.

Medical: Manufacturing surgical instruments, implants, and stainless steel housings with micron-level accuracy.

Electronics: Cutting precision enclosures, connectors, and circuit housings.

Furniture & Design: Enabling creative and customized designs in interior and industrial furniture.

As industries evolve, newer applications are emerging as well. For example, in renewable energy, Metal Laser Cutting is used in the production of wind turbine components and solar panel frames. In robotics, it enables the creation of lightweight yet durable parts for automated systems.

👉 Related: Custom Metal Electrical Enclosures

2025 marks a new era for Metal Laser Cutting, where traditional strengths are enhanced by digitalization, AI, and sustainability. Some key trends include:

Artificial Intelligence is revolutionizing how laser cutters operate. Modern systems can analyze cutting paths, predict tool wear, and automatically adjust parameters such as speed and laser intensity. This reduces human error and ensures maximum efficiency.

Metal Laser Cutting machines are now fully connected to Industry 4.0 ecosystems, allowing manufacturers to monitor production in real-time. Data on energy usage, downtime, and defect rates can be tracked to improve future processes.

With growing global demand for sustainability, Metal Laser Cutting is moving toward low-energy lasers and eco-friendly assist gases. Manufacturers are reducing scrap and recycling leftover materials, contributing to a circular economy.

Some companies are combining laser cutting with additive manufacturing (3D printing) to produce highly complex geometries, giving buyers more design freedom.

New generation fiber lasers can cut metals up to 60mm thick with smooth finishes, while also achieving ultra-fast cutting speeds for thin sheets, making the technology suitable for both heavy-duty and lightweight industries.

According to MIT Technology Review, the rise of AI-driven laser cutting systems is revolutionizing how factories maintain efficiency and quality.

👉 Related: Sheet Metal Bending Techniques

China remains one of the most competitive destinations for Metal Laser Cutting services. However, choosing the right supplier is critical. Consider the following factors:

Technical Expertise: Does the manufacturer specialize in your industry’s specific requirements?

Advanced Equipment: Do they use fiber lasers with automated CNC integration?

Customization Capabilities: Can they manufacture directly from your drawings and specifications?

Quality Control: Are they ISO-certified with a proven track record of inspections and testing?

Scalability: Can they handle both prototypes and mass production without delays?

Customer Support: Do they provide responsive communication and after-sales support?

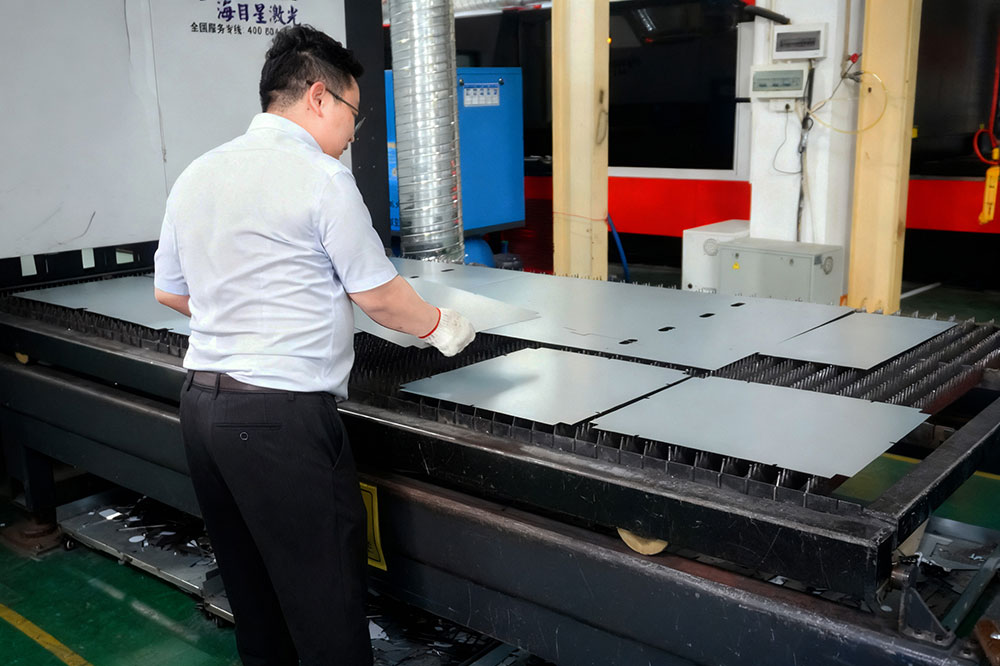

Shengwo Machinery has positioned itself as a trusted partner for global buyers seeking Metal Laser Cutting solutions in China. Our strengths include:

Customization – We specialize in producing parts directly based on client drawings, ensuring tailored solutions for every project.

Advanced Facilities – Equipped with the latest fiber laser cutting machines, CNC bending equipment, and welding capabilities.

Strict Quality Control – Multi-stage inspections from raw material sourcing to final product delivery.

Scalable Production – Capable of producing small prototype batches as well as high-volume runs.

Cost-Effectiveness – Competitive pricing without compromising on precision or reliability.

By choosing Shengwo Machinery, buyers gain access to a partner committed to both technical excellence and long-term collaboration.

Q1: What materials can be cut with Metal Laser Cutting?

A: Stainless steel, aluminum, titanium, carbon steel, and copper alloys are commonly processed.

Q2: What thickness can Metal Laser Cutting handle?

A: Modern fiber lasers can cut up to 60mm thick materials while maintaining high-quality edges.

Q3: Is it cost-effective for small production runs?

A: Yes. Since no tooling is required, small batches can be produced without high setup costs.

Q4: Can Shengwo Machinery handle international orders?

A: Absolutely. We serve global B2B buyers with efficient logistics and export support.

Q5: How does Shengwo Machinery ensure accuracy?

A: We rely on advanced CNC controls, skilled operators, and strict inspection standards to guarantee precision.

Metal Laser Cutting has evolved from a high-tech option to a mainstream necessity in global manufacturing. Its precision, speed, and versatility make it a critical solution for industries seeking innovation and efficiency. In 2025 and beyond, buyers who align with manufacturers that adopt AI, smart factory integration, and sustainable practices will gain significant competitive advantages.

👉 Looking for a reliable Metal Laser Cutting manufacturer in China? Contact Shengwo Machinery today for customized solutions based on your drawings and project requirements.