Providing precision metal processing solutions for high-end industries | SHENGWO

Shengwo specializes in precision metal processing, offering high-quality custom parts for industries like kitchen equipment, electronics, and more.

Company Profile

Zhuhai Shengwo Machinery Technology Co., Ltd. (hereinafter referred to as Shengwo Machinery) is the preferred manufacturing partner for many enterprises, including one of Schneider Electric’s SAM audited green suppliers, a Fortune 500 company. And has been honored with the Schneider Electric Quality Rising Star Award. Shengwo has won many honorary certifications such as “National High-tech Enterprise” and “Technology-based Small and Medium Enterprises”, ISO system, and patented technology with its outstanding technical strength and innovation capabilities.Certified to ISO 9001 :2015(Quality Management) and ISO 14001 :2015(Environmental Management) by a UKAS accredited body, recognized by the IAF.

Shengwo Machinery focuses on designing and manufacturing diverse products that can improve the world for its customers. Currently, the company has been awarded the title of “National High-tech Enterprise” and has received the “Science and Technology-based Small and Medium-sized Enterprise” award for three consecutive years. Shengwo Machinery provides innovative technologies, supply chain services, and advanced manufacturing solutions to multiple industries, including automotive, medical, communications, cloud computing, industrial, consumer electronics, and retail.

Shengwo Machinery is committed to promoting the development of Industry 4.0 and intelligent manufacturing in China and strives to create a diverse and inclusive corporate culture and work environment. With a 3,000-square-meter production base and office space, Shengwo Machinery has implemented an ERP digital management model reform since 2024, aiming to build a one-stop service factory integrating R&D, reliability testing, structural component production and assembly, finished product assembly and packaging, and logistics capabilities.

Company Vision: To become the world’s most innovative precision sheet metal parts integrated solution manufacturing service provider.

Our professional R&D and design team continuously develops and updates hardware metal manufacturing processes to meet the needs of market expansion.

We have a full range of precision metal processing equipment to provide you with fast, high-quality product development and production customization needs.

We have a production base of 20,000 square meters and conduct quality inspections from materials to shipment to ensure that each product is 100% qualified.

More than 30 people in foreign trade sales and after-sales, providing quotation and after-sales service in the fastest 30 minutes

What Does SHENGWO do?

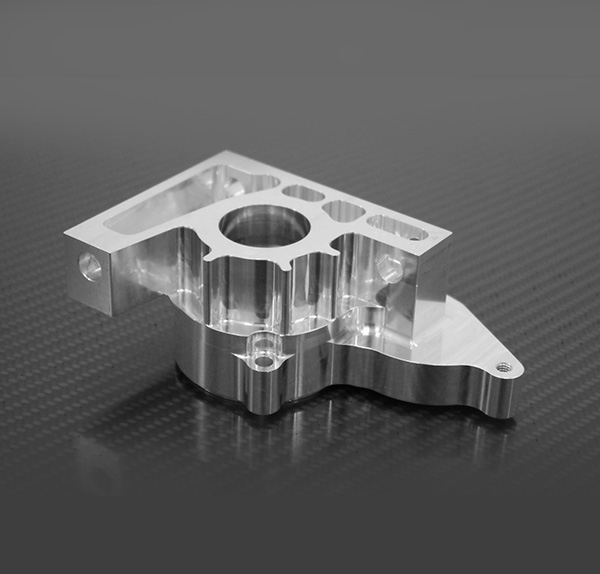

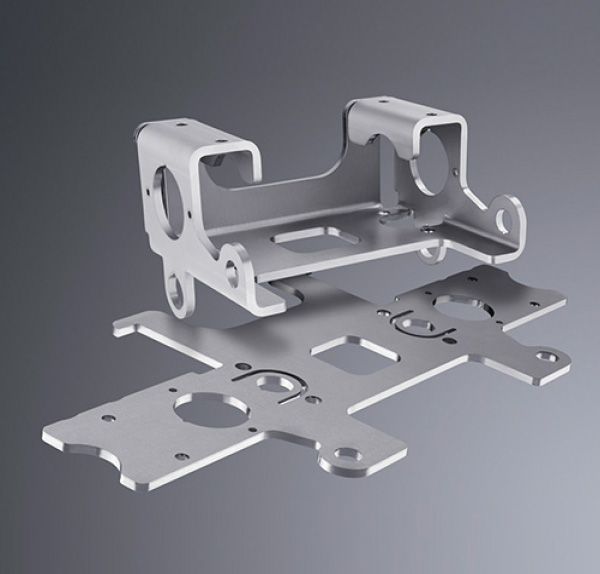

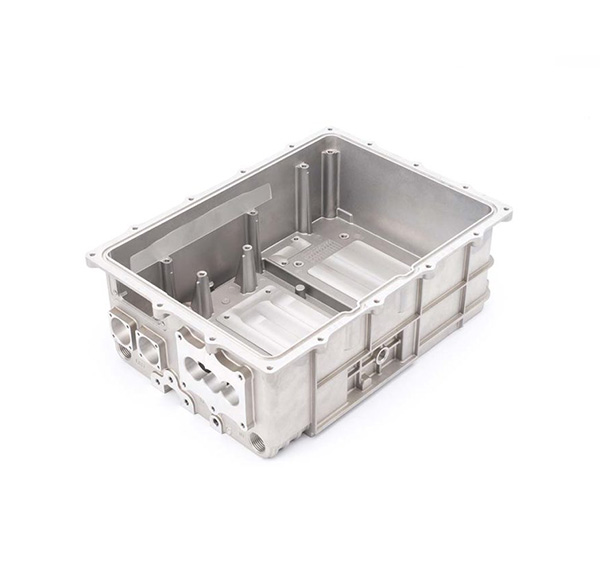

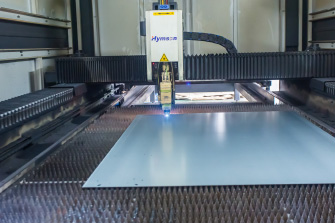

SHENGWO is committed to providing top quality rapid prototyping and low volume manufacturing service, integrating laser cutting, precision bending and efficient welding, providing customers with a series of surface treatment supporting production services such as cnc precision metal processing customization,sheet metal processing, metal stamping, electroplating, spraying, etc.

We provide high quality manufacturing solutions that can have your design finished in a matter of hours. This gives you the opportunity to rigorously test your product, and make all the needed changes to perfect your design before it goes into full-scale production.

What Can You Expect From SHENGWO?

★Saving money through our low-volume manufacturing process

★Faster time to market (and a higher success rate)

★Creating flexible design options for all your products

★Supplying you with a comprehensive option for bridge production

View Our Factory And Facilities

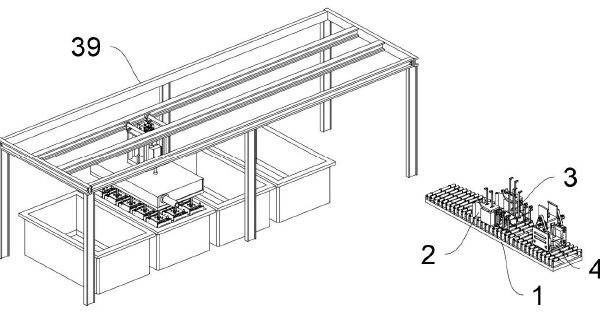

Shengwo Machinery is committed to innovative and efficient precision metal processing solutions.It is equipped with laser cutting, precision bending, efficient welding equipment and its own invented sheet metal surface multi-stage processing equipment system to provide customers with cnc precision metal processing customization,sheet metal processing, metal stamping, electroplating, spraying and other surface treatment supporting production services.

Invention patent

Lean Site Management

At Shengwo Machinery, we utilize 5S and visual management to create a standardized, visually-based production environment, improving efficiency and ensuring the high quality of every product.

At Shengwo Machinery, we understand that an efficient and stable manufacturing process is inseparable from rigorous and orderly site management. We fully implement 5S (sort, set in order, sweep, clean, and maintain quality) throughout production, continuously optimizing the work environment to achieve “visible problems, manageable processes.”

Incorporating visual management principles, we manage tools, equipment, and materials using fixed locations. All work processes, quality standards, and process requirements are clearly visible through diagrams and labels, ensuring that every employee can quickly identify issues and standards.

This highly standardized and standardized approach not only improves production efficiency but also minimizes human error, providing customers with stable, high-quality sheet metal parts and custom racking solutions.

Quality & Honor

Certifications

SHENGWO has many invention and utility patent certificates. The production strictly implements international quality control standards to ensure product quality. It has passed lSO 9001, lSO14001, SGS certifications.