ผู้ผลิตโซลูชันฮาร์ดแวร์แม่นยำที่ปรับแต่งได้

Contents

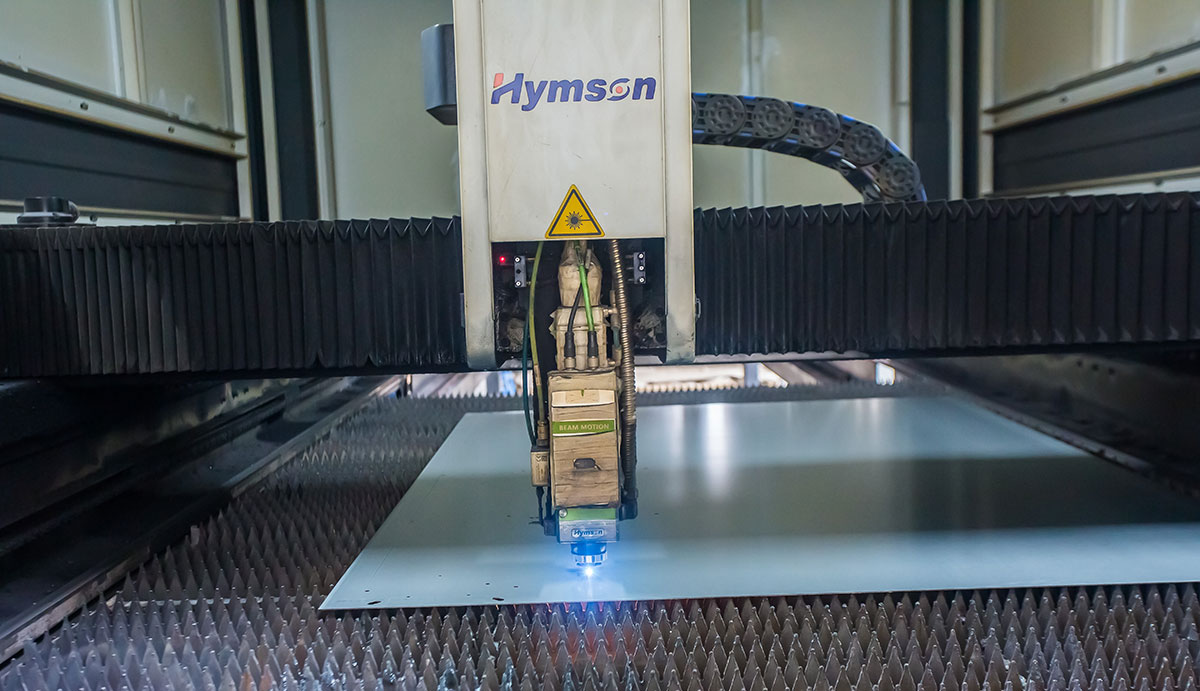

Sheet metal cutting redefines manufacturing in 2024 with advanced techniques, offering precise solutions for intricate designs and functional components.

Sheet metal cutting is a cornerstone of modern manufacturing, offering endless possibilities for creating intricate designs and functional components. In 2024, cutting sheet metal has evolved beyond industrial applications, becoming a medium for artistic expression and innovation. Our collaboration with UK artist and designer Scott Donnelly exemplifies the synergy between technology and creativity. This article explores the techniques, applications, and benefits of sheet metal cutting, highlighting how advanced methods and collaborative approaches redefine industry standards.

Sheet metal cutting involves dividing metal sheets into specific shapes and sizes using a variety of methods. Precision is paramount in achieving desired results, whether for functional components or artistic designs. Common materials include aluminum, steel, stainless steel, and brass, each chosen for its unique properties such as strength, flexibility, or aesthetic appeal.

With advanced technology, cutting sheet metal transcends functionality, enabling the creation of bespoke designs. Collaborations between engineers and artists like Scott Donnelly illustrate how technology can breathe life into creative visions.

In 2024, we partnered with UK artist and designer Scott Donnelly to merge advanced technology with unique artistic concepts. This collaboration exemplifies how sheet metal cutting can go beyond manufacturing to produce innovative and visually striking installations.

By integrating cutting-edge equipment and creative input, we provide clients with original solutions tailored to their needs. This approach ensures both functional excellence and aesthetic appeal.

Technologies like laser cutting achieve unparalleled precision, ensuring high-quality results for intricate designs and industrial parts alike.

Cutting sheet metal allows for limitless customization. Clients can present themes or images, and we transform their ideas into reality using advanced machinery.

Modern cutting methods minimize material waste and reduce energy consumption, aligning with sustainable manufacturing practices.

Cut metal components offer superior strength, ideal for applications requiring durability, such as construction, automotive, and aerospace industries.

Scott Donnelly’s laser-cut sculptures, created in collaboration with Shengwo engineers, exemplify the perfect union of art and technology. These pieces showcase intricate details achievable only through precision sheet metal cutting.

By working with construction and architecture industries, we’ve created installations that are both functional and visually stunning, transforming spaces into works of art.

Our ability to craft bespoke work from client-provided themes demonstrates our commitment to delivering customized solutions that exceed expectations.

Sheet metal cutting continues to evolve as a vital process in manufacturing and design. By combining advanced technology with creative collaboration, we push the boundaries of what is possible. Our partnership with Scott Donnelly exemplifies this approach, producing innovative solutions for diverse industries. Whether for industrial components or artistic installations, precision sheet metal cutting redefines the standard of excellence.

Let’s build something extraordinary together—combining creativity and technology for results that inspire.