China Metal Laser Cutting Services

Shengwo offers metal laser cutting services with high precision, maximizing material use and accommodating complex designs in China. Our advanced machines and strict quality control ensure custom metal parts meet exact specifications for perfect results every time.

Metal Laser Cutting Services at SHENGWO

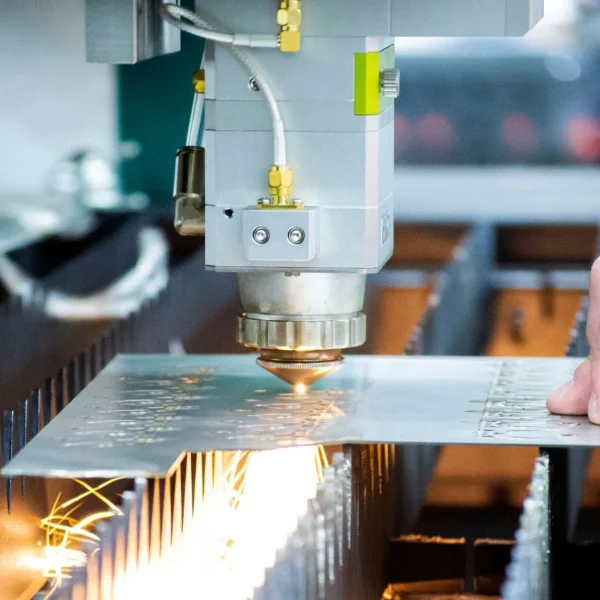

Metal cutting laser is an extremely effective process for cutting plate or sheet metal and an excellent solution for customers working with difficult profiles requiring tight tolerances and high speed cutting.

Exceptional Quality Parts

Using advanced metal laser cutting technology, we ensure exceptional precision on every project. Strict quality control processes ensure that your custom metal parts meet exact specifications and ensure that every order is delivered perfectly.

Fast Delivery

Experience industry-leading delivery speeds. Through efficient online systems and streamlined production processes, we minimize delivery times, allowing you to receive laser cut parts faster and stay competitive in the market.

Professional Engineer Support

Our engineering team is dedicated to turning design challenges into viable solutions. We provide professional support to ensure that your custom metal laser cutting project receives the best technical advice and design optimization to achieve excellent results.

What is Laser Metal Cutting?

Laser Metal Cutting is a non-contact technology that uses precise heat energy to cut materials. Using a highly concentrated laser beam as a heat source, it can vaporize, melt, burn, or blow away surface material to achieve a smooth cut. This advanced technique is widely used in creating custom laser cut metal ornaments, ensuring intricate details and high-quality finishes.

Remote cutting:

Remote cutting is a technology that does not require the use of cutting gas and cuts metal by partial ablation. The low energy input makes remote cutting ideal for thin and delicate plates.

Flame cutting:

Flame cutting is a process that ignites the surface of steel through the reaction of oxygen with natural gas or acetylene. This relatively slow cutting method has a large heat-affected zone and is suitable for cutting thicker materials.

Fusion cutting:

Fusion cutting uses argon or nitrogen as a cutting gas to blow away the molten metal. These inert gases prevent oxidation reactions, ensuring that the surface quality meets the required standards and reduces the need for subsequent processing.

At SHENGWO, whether you need a single prototype, small batch or large-scale production, our capabilities can easily support it. We use advanced laser cutting machines that can handle complex designs and provide consistently high-quality results.

Our Laser Metal Cutting Machining Capabilities

Our custom laser cutting service follows international industry standards and market trends to provide our customers with quality laser cut parts:

Maximum part size:

10 mm (0.40 in.)

Minimum part size:

2 times the material thickness, minimum thickness is 1 mm (0.04 in.)

Achievability:

+/- 0.05 mm (0.002 in)

Positioning accuracy:

+/- 0.10 mm (0.004 in)

Delivery time:

5-7 days

We are equipped with a Trumpf TruMatic 1000 3KW fiber laser and punch combination machine, offering exceptional flexibility for cutting mild steel, stainless steel, aluminum, and non-ferrous metals. This advanced system integrates both laser cutting and punching, enabling multiple processing capabilities within a single setup. The fiber laser ensures precision, delivering clean, highly accurate cuts ideal for intricate designs and complex geometries.

In addition to sheet metal processing providing high-precision cutting for medical and industrial applications. Our advanced laser technology ensures smooth, burr-free edges and intricate patterns, meeting the stringent requirements of hypotube manufacturing.

Leverage our expertise and cutting-edge technology for your Laser Cut Hypotube Solutions and sheet metal projects. Partner with us to achieve precise, reliable, and superior results with every cut.

Request a quote today to get started.

Why is Shengwo Different ?

Competitive Price

We are well aware of the key to quality and cost, and are committed to providing excellent quality without exceeding the budget. Through efficient production processes and optimized manufacturing strategies, we are able to reduce costs and directly return the savings to you, ensuring that you get the best value for money.

Comprehensive support and quality service

We provide first-class materials, professional technical support and a full range of packaging services to ensure that your customization needs are met. Our team prioritizes responding to customer needs, quickly resolving quality issues, and ensuring on-time delivery, giving you peace of mind.

Strong production capacity

With more than 10 years of experience in precision metal processing, we have brought together a professional team, including technical talents such as sales, customer service, process analysts, quotation personnel, process engineers and programmers. There are about 60 employees, 70% of whom are business elites, technical backbones and production experts to ensure that our production capacity is always at the leading level in the industry.

Flexible equipment configuration

We have over 20 advanced machines for thin metal laser cutting services, drilling, folding, stamping, welding, painting, and electroplating. Whether you need small batch customization or large-scale production, we provide flexible solutions to ensure perfect results for every project.

Application of Laser Cutting in China

Hypotube

With the ability to create both functional and decorative patterns, laser cut hypotubes solutions combine strength with aesthetic appeal, offering a versatile solution for custom tube fabrication.

Ornaments

Custom laser cut metal ornaments offer unique, intricate designs, perfect for personalized decor and gifts.

Thin Metal

Our thin metal laser cutting services provide precise, detailed cuts for various applications, ensuring high-quality results every time.

Privacy Screens

Laser cut metal privacy screens offer stylish, durable solutions for outdoor and indoor spaces, providing privacy, shade, and modern aesthetics with customizable designs.

Improve production efficiency by 30%! Explore our high-speed laser cutting process

Are you still worried about low production efficiency and cost control?

In the field of Shengwo Hardware Custom Sheet Metal Processing, high-speed metal cutting laser is redefining efficiency and quality. Compared with traditional metal cutting laser, our high-speed metal cutting laser technology improves production efficiency by 30%, ensuring faster delivery, reducing downtime, and significantly reducing production costs.

📈 Our advantages:

✔ Improve production efficiency: fast cutting, saving time, and shortening delivery cycle.

✔ Higher precision: Ensure that each cutting edge is smooth and perfectly meets design requirements.

✔ Cost savings: By improving efficiency and reducing the processing cost per unit product, you can help reduce overall production expenses.

✔ Adapt to a variety of materials: Whether it is metal, aluminum, or stainless steel, our technology can easily handle it.

FAQs About Laser Metal Cutting

Our metal cutting laser services are engineered for high precision, offering a cutting accuracy of +/- 0.002 inches and positional accuracy of +/- 0.004 inches. This precision guarantees that every part we produce adheres to your exact specifications, ensuring the highest quality in the final product. Whether working with intricate designs or exact part replication, our advanced laser cutting technology is perfect for projects that require detailed accuracy, making it ideal for industries that demand precision.

Yes, we provide both laser engraving and etching services. like laser cut hypotube solutions. With our extensive expertise in these techniques, we deliver high-quality results tailored to your specific needs. Whether you require detailed graphics, precise text, or intricate patterns, our laser engraving and etching services offer a high-resolution finish on various materials. Each project is handled with precision to ensure your product leaves a lasting, professional impression, making it ideal for both aesthetic and functional purposes.

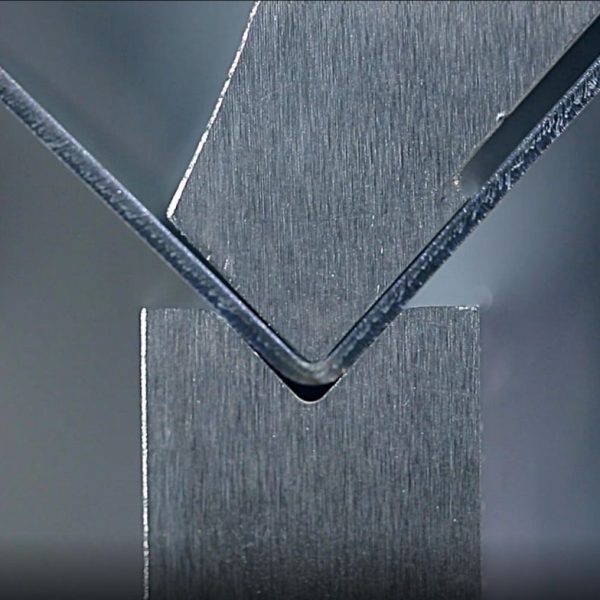

Absolutely. In addition to laser cutting, we offer a range of material bending options, including V-bending, roll bending, rotary bending, and wipe bending. These techniques allow us to shape your flat profiles into the desired forms. The choice of bending method is based on your project’s specific requirements, providing the flexibility needed to meet diverse applications and ensuring the final product matches both design and functional needs.

The time required for laser cutting depends on several factors, including the complexity of the design, material type, and thickness. Simple designs on thinner materials are typically completed quickly, often within a few hours, while more complex or intricate designs and thicker materials may require more time. We strive to optimize our processes for fast turnaround times without sacrificing quality. To get a precise timeline for your project, please reach out directly, and we’ll provide a customized estimate based on your exact specifications.

คุณภาพและเกียรติยศ

การรับรอง

SHENGWO มีใบรับรองสิทธิบัตรสิ่งประดิษฐ์และสิทธิบัตรการใช้งานมากมาย การผลิตใช้มาตรฐานการควบคุมคุณภาพระดับสากลอย่างเคร่งครัดเพื่อให้แน่ใจถึงคุณภาพของผลิตภัณฑ์ ผ่านการรับรอง ISO 9001, ISO4001 และ SGS

ติดต่อเรา

Looking for precise and efficient Metal Laser Cutting solutions? At Shengwo, we specialize in delivering high-quality, custom metal parts that meet your exact specifications. Whether you need prototypes, low-volume production, or complex designs, our advanced technology and skilled engineers are here to help.

Reach out today for a fast, competitive quote and see how our precision cutting services can help you achieve the perfect results. Let us turn your ideas into reality with the precision and reliability you deserve!

Inquiries

For any inquiries, questions or commendations,

please call: +86-13726228398

or fill out the following form

บริษัท จูไห่เฉิงโวแมชชีนเนอรี่เทคโนโลยี จำกัด

Address :

เลขที่ 8803 Zhuhai Road, LianWan Industry Park, Jinwan District, 519090 Zhuhai, Guangdong, China

P:+86-13726228398

T:+86-0756-6121108

E:Young.wen@zhswjx.com