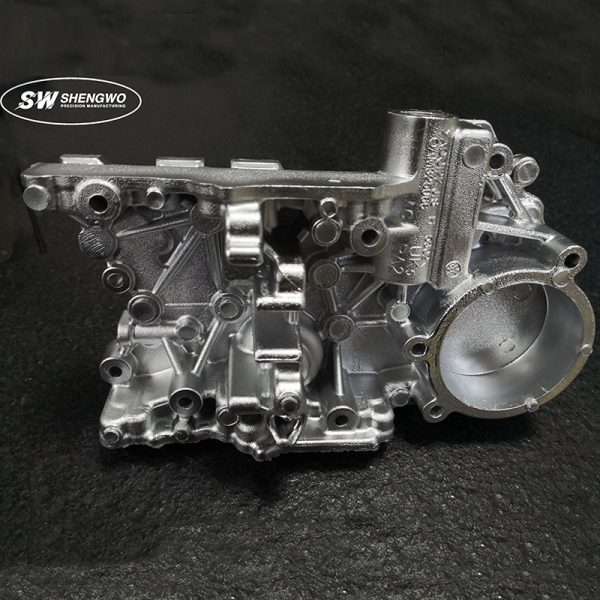

Die Casting Mold Solutions

Need reliable die casting mold solutions? Shengwo ensures fast turnaround and cost-effective production, maximizing efficiency.

Die Casting Mold Services at Shengwo

Shengwo is a leading die casting manufacturer with extensive expertise in both die casting and plastic parts production. Our skilled engineers have a deep understanding of your design intentions and consistently offer valuable suggestions to accelerate production while minimizing costs. We excel at optimizing plastic and metal parts for perfect fit and functionality, helping you save both time and money.

01

Quality & Price

By heavily investing in advanced die casting machinery, manufacturing facilities, and precision measuring tools, our metal foundry can produce complex shapes with enhanced durability at a lower cost. Every product is meticulously crafted to meet customer specifications.

02

Delivery & Service

We ensure on-time delivery through professional packaging and partnerships with trusted logistics providers. Clear and prompt communication is maintained throughout the process to swiftly understand and address client needs.

03

Experience & Specialization

With extensive expertise in die casting production, mold design, and mold manufacturing, Shengwo’s skilled technicians are proficient at identifying and resolving issues during production, ensuring high-quality results.

What is Die Casting mold and How Does It Work?

Die casting is an efficient and precise manufacturing process used to produce complex metal parts with high accuracy and smooth surface finishes. It begins with the creation of steel molds, known as dies, which are custom-made for the specific metal parts or components you want to manufacture. These molds act as detailed templates that shape the molten metal into intricate designs.

Once the molds are ready, the next step involves selecting the main materials for the metal parts, such as aluminum, zinc, or other alloys known for their strength and lightweight properties. The chosen metal is then melted until it reaches a liquid state. Using high pressure, the molten metal is injected into the steel mold, ensuring that it fills every intricate cavity and captures all the design details.

After the mold is fully filled, the molten metal is allowed to cool and solidify. Once it hardens, the newly formed metal part is carefully ejected from the mold. This results in a die-cast component that is highly durable and ready for use in product assembly or further processing, such as machining or surface finishing.

As a leading china die cast mold company, Shengwo specializes in providing high-quality aluminum die casting and zinc die casting services. We are dedicated to meeting our customers’ needs by delivering reliable and cost-effective solutions for their manufacturing requirements.

Benefits of Die Casting

Die casting is an efficient manufacturing method that allows for the creation of complex metal parts and components with intricate shapes and detailed designs. It also offers faster production speeds compared to other manufacturing techniques, making it an ideal choice for producing metal prototypes and hardware parts at scale.

● Versatile Material Options

Die casting provides the flexibility to choose from a wide range of metal materials suitable for different applications. For instance, copper can be used to manufacture metal parts with high electrical conductivity, while other metals like aluminum and zinc offer lightweight yet durable solutions for various industries.

● Complex and Detailed Designs

The die casting process is ideal for producing complex designs with high precision. Whether it’s for automotive components, electronic housings, or decorative parts, the ability to create intricate steel molds enables manufacturers to achieve detailed and accurate designs that meet specific requirements.

● High Production Efficiency

One of the standout advantages of metal die casting is its rapid production speed. This method not only accelerates the manufacturing process but also reduces costs, making it a cost-effective solution for mass-producing metal parts. Its high-speed production capability is perfect for industries needing large quantities of uniform components.

● Superior Surface Finish

Compared to other manufacturing techniques, die cast parts have a noticeably smoother surface finish. This results in aesthetically pleasing products that require minimal post-processing. For example, metal parts produced for die-cast vehicles benefit from the smooth and polished appearance achieved through this method.

なぜ聖和は 違う ?

強力な生産能力

当社は精密金属加工の分野で10年以上の経験があり、営業、顧客サービス、プロセス分析、見積担当者、プロセスエンジニア、プログラマーなどの技術人材を含む専門チームを結成しています。従業員は約60名で、そのうち70%はビジネスエリート、技術バックボーン、生産専門家であり、当社の生産能力が常に業界のトップレベルにあることを保証しています。

柔軟な設備構成

金属部品の多様なニーズに応えるため、当社は金属レーザー切断、穴あけ、折り曲げ、スタンピング、溶接、塗装、電気メッキなど、20 を超える先進的な設備を備えています。小ロットのカスタマイズでも大規模生産でも、各プロジェクトの完璧な実行を確実にするために柔軟に対応できます。

競争力

価格

当社は品質とコストの鍵を熟知しており、予算を超過することなく優れた品質を提供することに尽力しています。効率的な生産プロセスと最適化された製造戦略を通じてコストを削減し、その節約分を直接お客様に還元することで、最高のコストパフォーマンスを実現しています。

包括的なサポートと質の高いサービス

当社は、お客様のカスタマイズ ニーズを確実に満たすために、最高級の素材、専門的な技術サポート、および包括的なパッケージング サービスを提供しています。当社のチームは、お客様のニーズへの対応、品質問題の迅速な解決、納期厳守を最優先に考えており、お客様に安心感を与えています。

Materials Used For Die Casting

Magnesium Alloys

1. Ultra-Lightweight: Magnesium alloy die casting produces the lightest metal components, ideal for weight-sensitive applications.

2. High Strength-to-Weight Ratio: Despite its lightness, magnesium die-cast parts maintain impressive strength, ensuring durability.

3. Excellent Damping Capacity: Magnesium alloys absorb vibrations, making die-cast parts ideal for noise and vibration reduction.

4. Rapid Production: Magnesium's properties allow for faster die casting cycles, leading to quicker production times.

5. Eco-Friendly: Magnesium die casting is recyclable and requires less energy in production, supporting sustainable manufacturing.

Aluminum Alloys

1. Lightweight & Strong: Aluminum die casting delivers robust components without added weight.

2. Corrosion Resistance: Aluminum die-cast parts naturally withstand corrosion, ensuring longevity.

3. Malleability: Aluminum's adaptability allows for intricate die-cast designs.

4. Cost-Effective: Aluminum's abundance makes die casting more affordable.

5. Thermal Conductivity: Aluminum die casting excels in heat dissipation, ideal for heat-sensitive components.

Zinc Alloys

1. Precision & Detail: Zinc alloy die casting allows for high-precision components with intricate details.

2. High Strength: Zinc die-cast parts offer exceptional durability and resistance to wear.

3. Ease of Casting: Zinc's fluidity makes it ideal for die casting, ensuring smooth and defect-free components.

4. Extended Lifespan: Zinc alloy die-cast parts are resistant to environmental impacts, ensuring a longer product life.

5. Cost-Effective Finishing: Zinc die casting achieves a smooth finish, reducing post-processing costs.

FAQs About Die Casting Mold

Precision die casting is a highly specialized process where molten metal is injected into a die casting mold under high pressure. This method ensures that each cast part is produced with intricate details, uniformity, and exceptional dimensional accuracy. The precision and consistency make it the preferred choice for industries that require high-quality, precision components.

The versatility of die casting molds makes them popular across various industries. In the automotive sector, die casting is used to produce engine components, while the electronics industry uses it to create housings and connectors. The aerospace industry benefits from die casting molds to create lightweight yet durable parts, and the household appliance sector relies on die casting for both functional and aesthetically pleasing components.

When selecting a die casting mold service provider, it’s important to choose one with a solid reputation for delivering high-quality components. Look for a supplier that uses advanced machinery, adheres to stringent quality control procedures, and offers design as well as post-processing services. This ensures that the final product meets your exact specifications.

Flash in die casting molds refers to excess material that forms around the parting surfaces of the mold. This thin layer of unwanted metal can be removed during post-processing. Flash typically occurs when gaps or cracks in the casting surface allow excess molten material to escape, leading to this additional waste material.

Shengwo upholds strict quality standards in our die casting mold services to ensure the production of high-quality parts. We verify raw materials, control environmental conditions during production, and monitor all casting parameters to maintain consistency. Additionally, we provide Certificate of Compliance (CoC) documentation and perform thorough final inspections to ensure the highest quality assurance for every batch of parts.

品質と名誉

認証

SHENGWOは、多くの発明と実用新案特許証明書を持っています。生産は厳密に製品品質を確保するために国際的な品質管理基準を実装します。それは lSO 9001、lSO4001、SGS の証明を渡しました。

お問い合わせ

As one of the leading die cast mold manufacturers in China, Shengwo specializes in producing high-quality aluminum and zinc die castings using advanced machinery and state-of-the-art technology. In addition to precision die casting, Shengwo offers comprehensive services, including tooling and mold manufacturing, CNC machining, and a variety of surface treatments. As a trusted name in die casting mold China, Shengwo has experienced rapid growth due to its strict quality control, efficient production processes, expert engineering design, timely delivery, and competitive pricing.

お問い合わせ

お問い合わせ、ご質問、表彰など、

お電話ください:+86-13726228398

または以下のフォームにご記入ください。

珠海盛五機械技術有限公司

住所:

519090 広東省珠海市金湾区連万工業園珠海路8803号

P:+86-13726228398

T:+86-0756-6121108

E:Young.wen@zhswjx.com