Nhà sản xuất giải pháp tùy chỉnh phần cứng chính xác

Contents

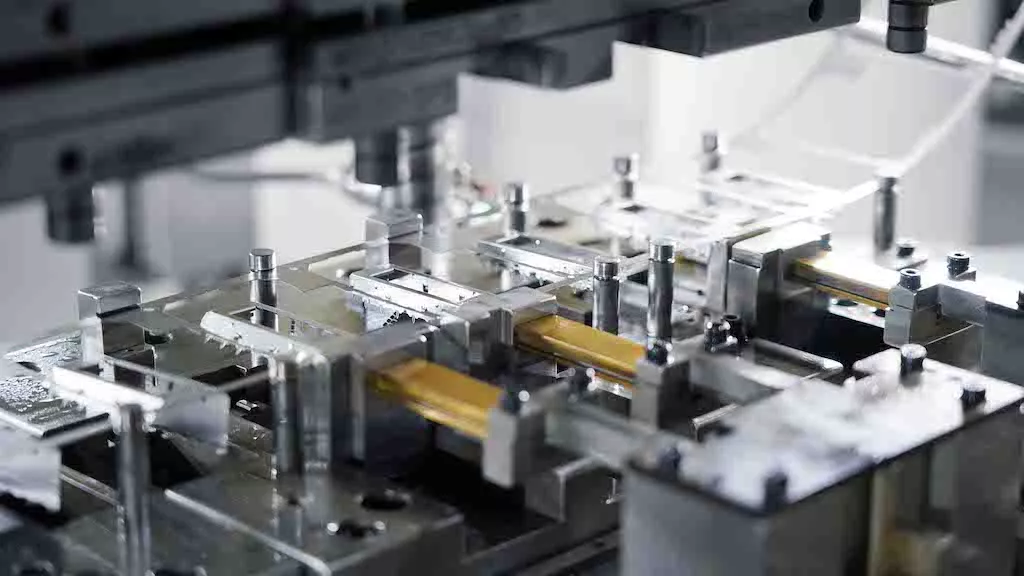

In modern medical and high-precision industrial applications, Hypotubes (thin-walled metal tubes) require exceptional precision and performance. Traditional machining methods often fail to meet the micrometer-level cutting requirements, making cắt laser technology the optimal solution.

With its high precision, non-contact processing, and minimal heat-affected zone (HAZ), laser cutting has revolutionized the way Hypotubes are manufactured. But what makes cắt laser so superior? How does it enhance efficiency in medical and precision manufacturing? Let’s dive deeper into this cutting-edge technology and its applications.

A Hypotube is a lifesaving technology used in various medical applications.

These thin, hollow tubes are critical in minimally invasive procedures, such as catheter-based interventions, micro-guidewires, and other precision instruments.

✔ Ultra-thin walls (typically <0.1mm)

✔ High strength and corrosion resistance

✔ Excellent flexibility and formability, allowing for complex designs

In catheter-based interventions, Hypotubes need to be small, flexible, and hollow to navigate blood vessels while allowing for tool control or drug delivery. However, achieving these characteristics requires extremely precise manufacturing, which traditional methods such as stamping, EDM, and mechanical cutting often struggle to deliver.

These conventional techniques can introduce burrs, thermal damage, or insufficient precision, making high-precision laser cutting the superior solution.

Wiseguyreports states that the Sea Wave Pipes market size is estimated at 1132.91 (USD Billion) in 2023. The seawave pipes market industry is projected to grow from 1184.46 (USD Billion) in 2024 to 1691.2 (USD Billion) by 2032. The Seawave Pipes Market CAGR (growth rate) is expected to be around 4.55% during the forecast period (2024-2032).

Laser cutting offers a non-contact, stress-free, and ultra-precise processing method, making it ideal for Hypotube applications. Laser systems must perform multiple tasks such as marking, cutting, and drilling on ultra-thin metal tubes. The most common solution involves medium-power fiber lasers, ensuring that all edges are burr-free and maintaining the integrity of the Hypotube structure.

✔ Unmatched Precision

Achieves cutting accuracy of ±5µm, meeting the extreme tolerances required for medical devices.

✔ No Heat-Affected Zone (HAZ)

Using femtosecond lasers, the process prevents material deformation and preserves mechanical properties.

✔ No Mechanical Stress

Unlike traditional cutting methods, laser cutting is tool-free, eliminating mechanical damage and deformation.

✔ Complex Geometries

Supports intricate patterns such as micro-holes, mesh structures, helical slots, and fine grooves, essential for medical and industrial applications.

✔ Compatible with Multiple Materials

Suitable for stainless steel (SS304, SS316), nitinol (Nitinol), titanium alloys, aluminum alloys, and more.

✔ Catheter Shafts

Laser-cut Hypotubes enable catheters with precise flex control, enhancing navigation in complex vascular structures.

✔ Vascular Stents

High-precision laser cutting creates intricate mesh structures, ensuring optimal flexibility and durability.

✔ Needles & Infusion Devices

Ultra-thin Hypotube needles require smooth, burr-free edges, which laser cutting guarantees.

✔ Micro-Sensors & Electronic Packaging

Laser-cutting technology ensures high-precision micro-holes and channels for advanced electronic applications.

✔ Aerospace & Semiconductor Components

Complex microfluidic structures require extreme precision, which laser cutting provides with no warping or heat distortion.

Different Hypotube applications demand different laser cutting technologies. Below is a comparison of the most commonly used laser types:

| Laser Type | Best for | Key Features |

|---|---|---|

| Femtosecond Laser | High-end medical devices, ultra-precision machining | No heat-affected zone, sub-5µm accuracy |

| Fiber Laser | High-volume production, rapid cutting | Ideal for thin-walled metals, cost-effective for mass production |

| CO₂ Laser | Non-metal materials (plastics, ceramics) | Less effective for metal Hypotubes |

For high-end medical applications, femtosecond lasers provide the best precision. However, for mass production, fiber lasers offer a high-speed and cost-effective solution.

With advancements in AI and automation, Laser Cut Hypotube solutions are evolving toward smart, highly automated manufacturing:

🚀 AI Vision Inspection

Automatically detects cutting defects, ensuring zero-error production.

🚀 Robotic Automation

Enhances efficiency by automating material handling, reducing human intervention.

🚀 Big Data Optimization

AI adjusts laser power, focal distance, and processing parameters for maximum precision and consistency.

These innovations make laser-cut Hypotube solutions more efficient, stable, and future-ready, meeting the demands of next-generation medical and industrial applications.

✅ Micron-level precision (<5µm), ideal for medical and high-end manufacturing

✅ Burr-free, no heat-affected zone, maintaining material integrity

✅ Supports intricate designs, including micro-mesh, holes, and flex-cutting

✅ Compatible with a variety of metals: stainless steel, nitinol, titanium, etc.

Looking for a high-precision Hypotube laser cutting solution? Liên hệ với chúng tôi today for customized processing services that meet the strictest quality standards.

📩 Get in touch for free samples and technical consultations!

Shengwo is a global manufacturing solution provider, dedicated to providing one-stop services from in-depth design to manufacturing for customers in various industries.

📌 Q1: What medical devices use laser-cut Hypotubes?

✅ Common applications include catheters, stents, minimally invasive surgical tools, and precision needles.

📌 Q2: What are the main advantages of laser cutting over mechanical machining?

✅ Non-contact processing, eliminating mechanical stress, with ±5µm precision.

📌 Q3: What is the most cost-effective laser cutting method for mass production?

✅ Fiber laser cutting is best for high-speed and large-scale production.