Rusting of metals is a comm

Rusting of Metals: Basic Causes

Metal rusting is primarily caused by electrochemical corrosion mechanisms. Taking iron as an example, in a humid environment, a micro galvanic cell forms on the surface of the iron. The iron undergoes oxidation, producing ferrous ions, while oxygen is reduced to hydroxide ions, ultimately forming iron oxide (rust). Factors such as the type of metal, humidity, temperature, and pollutants in the air all influence the rate of rusting.

Rusting Characteristics of Different Metals

Iron and steel are prone to rusting, with rust forming a porous structure that weakens the metal’s strength. Stainless steel, by adding chromium, forms a passivation layer that effectively prevents rust. When aluminum rusts, it forms an oxide layer that protects the metal, while copper rusts to form copper patina, which slows down further corrosion. Zinc, when paired with iron, offers cathodic protection by corroding first.

Metal Rusting Detection Methods

Physical methods include visual inspection and the use of magnifying glasses or microscopes to observe the rust layer. Chemical methods, such as drop tests, weight loss measurements, and chemical dissolution, are used to assess the extent of rusting. Non-destructive testing technologies like ultrasonic and eddy current testing can evaluate the thickness of rust layers and detect internal defects.

Rust Prevention Tips

- Stainless Steel: Stainless steel, an alloy of iron and chromium, forms a strong protective layer on its surface, effectively resisting oxidation and moisture. It’s an ideal material for preventing rust, especially for items exposed to the environment.

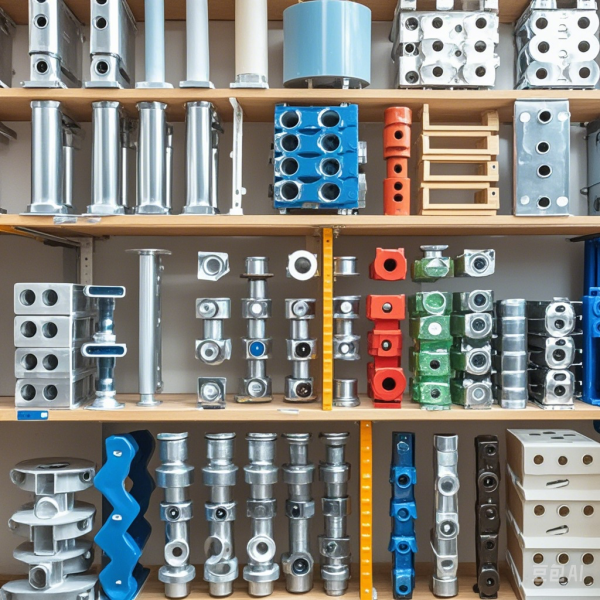

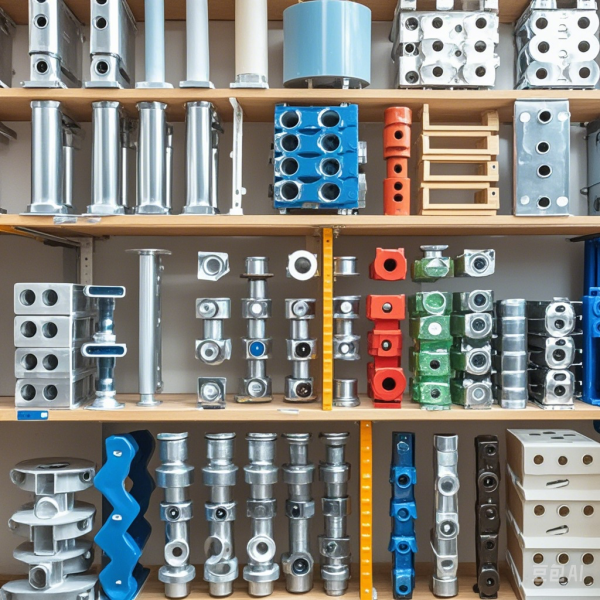

- Galvanized Metal: Galvanized metals, treated with a zinc oxide layer, form a protective coating on the surface, preventing rust. This material is especially suitable for tools and machinery exposed to moisture, with a long-lasting protective effect.

- Weathering Steel: Weathering steel, containing metals like copper, chromium, nickel, and zinc, offers excellent corrosion resistance due to its low porosity. It is ideal for outdoor machinery or tools, reducing maintenance costs.

- Coatings: Applying sealants or coatings on metal surfaces forms a physical barrier, preventing exposure to corrosive elements. There are various types of coatings available, such as oil-based or synthetic resin, which should be selected based on specific needs.

- Bluing Treatment: Bluing is a chemical process that forms a magnetite protective layer on metals, reducing oxidation. This is a common anti-rust treatment for tools and firearms.

- Anti-Rust Paint: Anti-rust paint contains additives that prevent corrosion, available in various colors and textures. It is suitable for protecting metal surfaces and maintaining rust-free conditions over time.

- Avoid Humid Environments: Rust occurs when moisture and oxygen react with metal. To prevent rusting, keep metals in dry places and ensure they are covered to prevent moisture exposure. Keeping the surface dry also helps prevent condensation.

- Proper Storage: Store metals in cool, dry areas, away from moisture. Outdoor storage should involve covering to prevent exposure to corrosive elements. Ensure metals are clean and dry before storage.

- Cathodic Protection: This method involves using electric current and sacrificial anodes to prevent corrosion. It is commonly used for metal structures exposed to water, such as pipelines and tanks.

- VCI Packaging: Volatile Corrosion Inhibitor (VCI) packaging releases molecules that form an invisible protective layer on metal surfaces, preventing rust, especially during transport.

- Regular Maintenance: Regularly inspect and clean metals to prevent rust from spreading. Keeping surfaces clean ensures coatings and protective layers remain effective.

- Design Considerations: When designing metal tools or machinery, consider rust prevention by choosing rust-resistant materials and ensuring exposed parts are effectively isolated from moisture and corrosive factors.

By implementing these preventive measures, metals can be protected from rust, extending their lifespan and reducing maintenance needs.

————about us————

Shengwo Machinery Technology Co., Ltd., as a bright new star in the wave of globalization, has quickly won the trust of various industries with its excellent technical strength, professional services and keen market insight, and has become a reliable partner.

Shengwoは、研究開発、生産、販売を統合した国際的な技術企業であり、ハイエンドの厨房機器、家電製品、医療機器、シャーシ、新エネルギー自動車、レーザー切断、治具などの業界向けにカスタマイズされた精密金属加工ソリューションを提供することに重点を置いています。絶え間ない技術革新と国内外の最先端技術の吸収と統合により、Shengwoは業界の発展をリードしています。

Click here to learn more about our company.