शीट मेटल वेल्डिंग सेवाएँ

Shengwo offers expert sheet metal welding services, ensuring strong, durable welds that meet the highest standards. We provide cost-effective welding solutions for industries demanding precision and reliability.

Sheet Metal Welding Services at SHENGWO

Our sheet metal welding services are critical for creating strong, durable, and precise welds that ensure your final products meet the highest quality standards. We utilize advanced equipment and welding technologies to deliver exceptional results for your sheet metal applications. Whether it’s for high-strength metal parts or components that must withstand harsh conditions, our services guarantee reliable and consistent welds at competitive prices. Trust us to provide the welding solutions that meet your exact specifications.

01

Exceptional Quality Parts

Our welding services focus on producing parts with impeccable weld integrity and strength. Using the latest welding technologies, we ensure each component is fabricated to withstand even the toughest conditions. You can count on our precision to meet or exceed your quality requirements.

02

Fast Delivery

Time is crucial, and we understand the need for quick turnarounds. At Shengwo, we prioritize fast delivery without compromising on quality. Our efficient processes ensure that your welded parts are ready when you need them, helping you stay on schedule.

03

Professional Engineer Support

Our expert engineers are here to provide personalized support and guidance throughout the process. Whether it’s optimizing designs or troubleshooting challenges, our team works closely with you to ensure your sheet metal welding needs are met with precision and expertise.

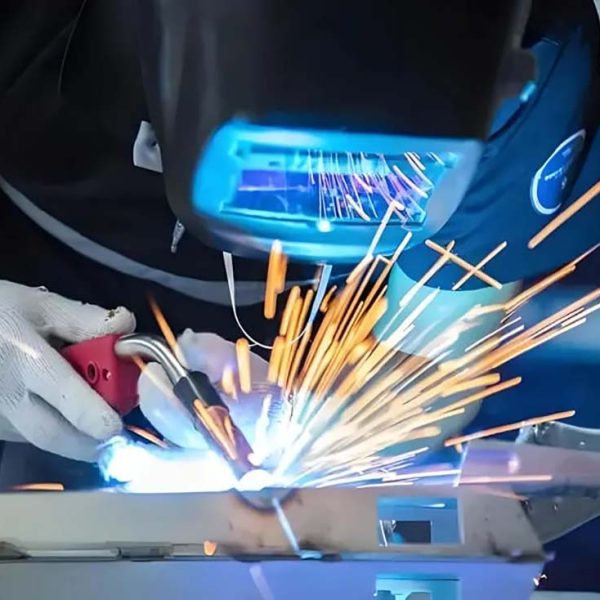

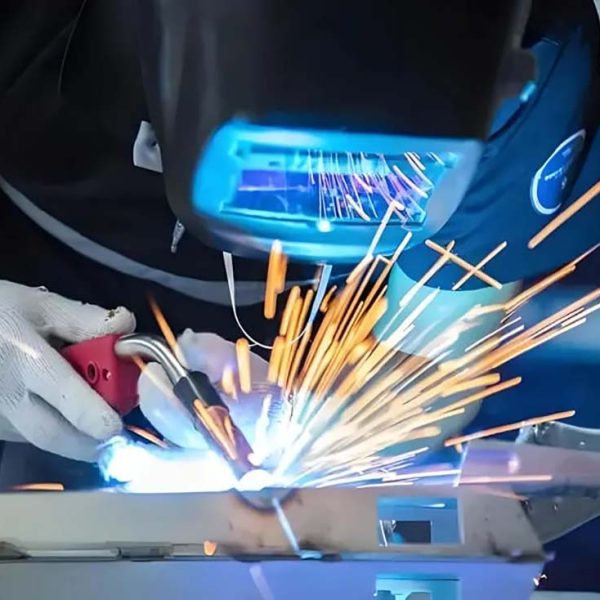

What is Welding Sheet Metal?

Sheet metal welding is a process that involves joining two or more metal sheets by heating and melting the metal, then fusing them together with a filler material. This creates a strong, durable joint that is essential for various industries, including automotive, aerospace, and manufacturing. Here’s why it matters for your business.

Strong and Durable Joints

Sheet metal welding creates joints that are capable of withstanding high stress and pressure, ensuring the durability and reliability of your products.Clean and Visually Appealing Welds

The welding process results in clean, smooth, and visually appealing welds that not only enhance the strength of your product but also its overall aesthetic.Precision for Thin Materials

Sheet metal welding excels at working with thin materials, providing precision and control to ensure a secure and tight joint, essential for delicate and lightweight applications.Versatility in Material Options

This process is highly versatile, capable of welding various metals such as aluminum, steel, copper, and brass, making it adaptable to a wide range of projects and industry needs.Increased Efficiency Through Automation

With the advancement of robotics and automated welding machines, sheet metal welding can be automated, significantly boosting production speed, consistency, and cost-effectiveness for both large and small production runs.

Our Welding Sheet Metal Machining Capabilities

We use advanced welding techniques to provide precision and high-quality results for all your sheet metal projects. Whether it’s for small batches or large-scale production, we ensure every weld is clean, strong, and reliable. Here’s a closer look at the key welding methods we use:

MIG Welding

Efficient and Versatile

MIG (Metal Inert Gas) welding is a highly efficient and versatile technique that ensures rapid fusion of metals. It's ideal for high-production projects, providing clean, solid welds for a wide variety of applications, from heavy machinery to light fixtures.

TIG Welding

Exquisite Craftsmanship Meets Strength

TIG (Tungsten Inert Gas) welding is known for its precision and ability to create aesthetically pleasing welds. It’s perfect for applications that require strong, critical joints, such as in aerospace, automotive manufacturing, and even artistic metalwork.

Spot Welding

Swift and Cost-Effective

Spot welding is a fast and efficient method for joining metal sheets. It’s commonly used in manufacturing and automotive industries where speed and durability are crucial. Spot welding ensures the precise and strong connections needed for your metal components, reducing production time and cost.

Why Choose Our Sheet Metal Welding Services?

With our state-of-the-art equipment and experienced team, Shengwo offers unparalleled welding services that meet the highest standards of quality and durability. Whether you’re looking for large-scale production or intricate, specialized pieces, we are committed to delivering flawless results every time.

Let us help you turn your metal fabrication projects into a reality with precision, efficiency, and cost-effectiveness.

Why is Shengwo Different ?

Strong production capacity

With more than 10 years of experience in precision metal processing, we have brought together a professional team, including technical talents such as sales, customer service, process analysts, quotation personnel, process engineers and programmers. There are about 60 employees, 70% of whom are business elites, technical backbones and production experts to ensure that our production capacity is always at the leading level in the industry.

Flexible equipment configuration

In response to the diverse needs of metal parts, we have more than 20 advanced equipment, including metal laser cutting, drilling, folding, stamping, welding, painting, electroplating, etc. Whether it is small batch customization or large-scale production, we can respond flexibly to ensure the perfect execution of each project.

Competitive

price

We are well aware of the key to quality and cost, and are committed to providing excellent quality without exceeding the budget. Through efficient production processes and optimized manufacturing strategies, we are able to reduce costs and directly return the savings to you, ensuring that you get the best value for money.

Comprehensive support and quality service

We provide first-class materials, professional technical support and a full range of packaging services to ensure that your customization needs are met. Our team prioritizes responding to customer needs, quickly resolving quality issues, and ensuring on-time delivery, giving you peace of mind.

How to weld sheet metal? Welding process, accurate and correct!

Do you encounter the following problems with your welding needs?

Unstable welding quality, resulting in poor product durability and even high rework rate? The welding process is not fine, and it is impossible to achieve the perfect combination of precision parts? The delivery cycle is too long, affecting the project progress and market opportunities? At Shengwo Machinery, we use precision welding technology to perfectly solve all your pain points! Watch the welding operation video demonstrated by our employees in person to feel how we seamlessly combine quality and innovation to ensure the high precision and high durability of each product.

🔧 Why choose Shengwo Machinery?

✔High precision: We have top welding equipment and experienced operators to ensure that each welding point meets customer standards.

✔Innovative design: Our welding solutions always keep up with the technological trend and solve the special needs of customers.

✔Fast delivery: Efficient production lines and welding processes enable us to complete delivery in the shortest time, helping you seize market opportunities.

FAQs About Sheet Metal Welding

TIG (Tungsten Inert Gas) welding is the ideal choice for welding thin metal sheets. It provides high precision, allowing welders to focus on a small, concentrated area of the metal. This precision ensures a smooth, clean, and delicate weld seam, which is essential when working with thinner materials. TIG welding is especially favored when the appearance and integrity of the weld are critical, as it minimizes heat distortion and provides excellent control over the welding process.

Both AC (Alternating Current) and DC (Direct Current) can be used for MIG (Metal Inert Gas) welding aluminum, but the choice depends on the specific requirements of the project. DC welding is the more commonly used method and tends to be faster and more efficient for welding aluminum. AC welding is often used for thicker aluminum materials, as it helps to clean the oxide layer on the metal’s surface, ensuring a better weld. For general aluminum welding, DC MIG welding is usually sufficient and more cost-effective.

Welding very thin metal requires skill and precision, as improper heat control can cause burn-through or distortion. With MIG welding, it is possible to weld metal sheets as thin as 0.8 mm, provided the heat is carefully regulated. For even thinner materials, such as 0.6 mm or less, TIG welding is the preferred method due to its superior control over the heat input, resulting in a more delicate and consistent weld without damaging the sheet. This level of precision makes TIG welding ideal for thin, delicate metals often used in high-precision applications.

The cost of sheet metal welding varies depending on several factors, including the type of welding process used (MIG, TIG, or others), the material being welded (aluminum, steel, etc.), and the complexity of the project. Projects that require intricate designs, multiple passes, or specialized materials may incur higher costs. Additionally, factors such as material thickness, welding speed, and finishing requirements can affect the final price. For an accurate quote, we recommend discussing your specific needs with us, and we will provide a detailed, competitive estimate based on your project’s unique requirements.

Sheet metal welding is versatile and can be used to weld a wide variety of metals. Common materials include aluminum, stainless steel, carbon steel, copper, and brass. Different materials may require specific welding techniques or filler materials to ensure a strong, durable weld. For example, aluminum may require additional precautions such as AC welding or the use of special welding rods to address its oxide layer. We have the expertise to handle all types of sheet metal materials and ensure high-quality welds for any application.

Welding involves high temperatures, intense light, and potentially hazardous fumes, so it’s essential to prioritize safety. Welders should always wear protective clothing, including flame-resistant jackets and gloves, to prevent burns and protect against flying sparks. Safety goggles or a welding helmet with an appropriate lens are crucial for shielding the eyes from the intense ultraviolet (UV) light and harmful infrared rays produced during welding. Additionally, welders should work in well-ventilated areas to minimize exposure to toxic fumes, and a fire extinguisher should always be nearby in case of an emergency. Proper safety training and adherence to safety standards are critical to preventing injuries and ensuring a safe working environment.

हमसे संपर्क करें

Looking for high-quality sheet metal welding solutions? At Shengwo, we specialize in providing precision welding services for a wide range of industries. Whether you need custom fabrications or large-scale production runs, our advanced welding technology ensures strong, durable, and flawless results every time.

Our expert team is here to provide tailored solutions to meet your exact specifications. Reach out today for a competitive quote and let us help you bring your project to life with precision sheet metal welding.

Inquiries

For any inquiries, questions or commendations,

please call: +86-13726228398

or fill out the following form

ज़ुहाई शेंगवो मशीनरी टेक्नोलॉजी कं, लिमिटेड

Address :

नंबर 8803 झुहाई रोड, लियानवान इंडस्ट्री पार्क, जिनवान जिला, 519090 झुहाई, ग्वांगडोंग, चीन

P:+86-13726228398

T:+86-0756-6121108

E:Young.wen@zhswjx.com