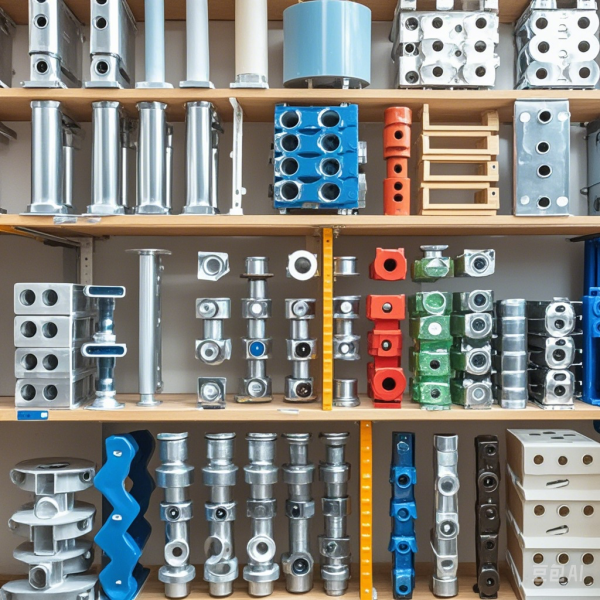

Quincaillerie de précision Fabricant de solutions personnalisées

Rusting of metals is a common phenomenon in both daily life and industry, significantly affecting the performance, lifespan, and appearance of metal products. Understanding the principles of rusting, the characteristics of rusting in different metals, detection methods, prevention measures, and repair treatments helps to effectively protect metal products and extend their service life.

Contents

Metal rusting is primarily caused by electrochemical corrosion mechanisms. Taking iron as an example, in a humid environment, a micro galvanic cell forms on the surface of the iron. The iron undergoes oxidation, producing ferrous ions, while oxygen is reduced to hydroxide ions, ultimately forming iron oxide (rust). Factors such as the type of metal, humidity, temperature, and pollutants in the air all influence the rate of rusting.

Iron and steel are prone to rusting, with rust forming a porous structure that weakens the metal’s strength. Stainless steel, by adding chromium, forms a passivation layer that effectively prevents rust. When aluminum rusts, it forms an oxide layer that protects the metal, while copper rusts to form copper patina, which slows down further corrosion. Zinc, when paired with iron, offers cathodic protection by corroding first.

Physical methods include visual inspection and the use of magnifying glasses or microscopes to observe the rust layer. Chemical methods, such as drop tests, weight loss measurements, and chemical dissolution, are used to assess the extent of rusting. Non-destructive testing technologies like ultrasonic and eddy current testing can evaluate the thickness of rust layers and detect internal defects.

By implementing these preventive measures, metals can be protected from rust, extending their lifespan and reducing maintenance needs.

Shengwo Machinery Technology Co., Ltd., as a bright new star in the wave of globalization, has quickly won the trust of various industries with its excellent technical strength, professional services and keen market insight, and has become a reliable partner.

Shengwo est une entreprise technologique internationale qui intègre la recherche et le développement, la production et la vente. Elle se concentre sur la fourniture de solutions personnalisées de traitement de précision des métaux pour les équipements de cuisine haut de gamme, l'électronique grand public, les équipements médicaux, les châssis, les véhicules à énergie nouvelle, la découpe au laser, les fixations et d'autres industries. Grâce à une innovation technologique continue et à l'absorption et l'intégration de technologies de pointe au niveau national et international, Shengwo est à la pointe du développement de l'industrie.

Click here to learn more about our company.