The great thing about modern sheet metal fabrication is the multitude offinishing options available to you to change the appearance of these humbleslabs of meta···

20

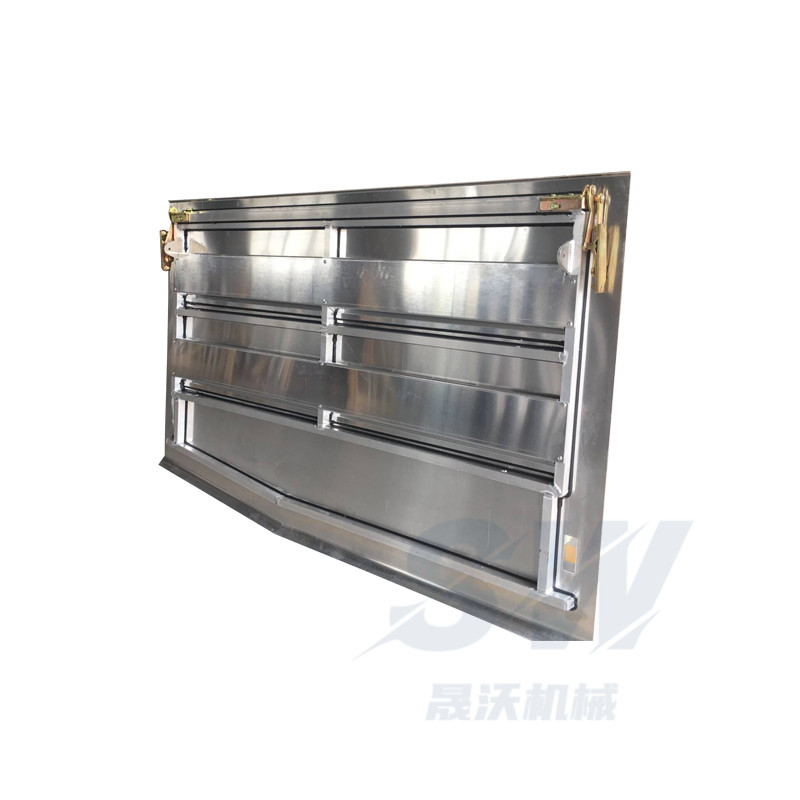

DecShengwo Machinery Products

We provide high quality products according to standard and professional technical service as wellShengwo Machinery Introduction

Providing customers with high quality, one-stop value-added services and products

Shengwo Machinery is a one-stop service company to provide customers with hardware processing (laser cutting, bending, welding), machining, metal stamping and electroplating, spraying a series of surface treatment supporting production. The company has passed ISO14001, ISO9001 certification and SGS ...

Learn moreShengwo Machinery Solutions

Provide targeted technical solutions for different industriesShengwo Machinery News

Technical articles and industry information20

DecThe great thing about modern sheet metal fabrication is the multitude offinishing options available to you to change the appearance of these humbleslabs of meta···

16

DecSheet metal fabrication is the construction of three-dimensional structures by cutting parts from metal sheets and machining them through brake and die presses ···

12

DecIn today's era of rapid technological development, the needs of the medical industry are also growing. As the core part of medical equipment, medical sheet ···

Welcome to browse our website, welcome to contact us for the latest product information and solutionsCONTACT US

contact usShengwo Machinery Products

We provide high quality products according to standard and professional technical service as wellShengwo Machinery Introduction

Providing customers with high quality, one-stop value-added services and products

Shengwo Machinery is a one-stop service company to provide customers with hardware processing (laser cutting, bending, welding), machining, metal stamping and electroplating, spraying a series of surface treatment supporting production. The company has passed ISO14001, ISO9001 certification and SGS ...

Learn moreShengwo Machinery Solutions

Provide targeted technical solutions for different industriesShengwo Machinery News

Technical articles and industry information20

DecThe great thing about modern sheet metal fabrication is the multitude offinishing options available to you to change the appearance of these humbleslabs of meta···

16

DecSheet metal fabrication is the construction of three-dimensional structures by cutting parts from metal sheets and machining them through brake and die presses ···

12

DecIn today's era of rapid technological development, the needs of the medical industry are also growing. As the core part of medical equipment, medical sheet ···

Welcome to browse our website, welcome to contact us for the latest product information and solutionsCONTACT US

contact ustime:2022-03-08 16:02:45hit:231

The application of laser welding technology used by our company in the new energy automobile industry: because of the fast speed of laser welding, easy to realize remote control and automatic production, it is widely used in the automobile manufacturing and new energy battery production and other industries with a higher degree of automation. With the development of the new energy automobile market in recent years, it also drives the market demand for laser welding equipment. Data show that the market size of laser welding equipment in China increased from 1.86 billion yuan to 15.13 billion yuan from 2016 to 2023. The main application processes in the automotive industry include laser welding of unequal thickness plates, laser welding of body assembly and sub-assembly, laser welding of automotive parts. In the field of power batteries, the explosion-proof valve sealing welding, pole ear welding, soft joint welding, safety hat spot welding, battery shell sealing welding, module and PACK welding and other processes, all use laser welding as the best process. The application of laser welding technology in automobile body can reduce the body weight to achieve the purpose of fuel saving. The firmness and lightness of laser welding technology can improve the degree of body integration. Laser welding technology has high precision and high efficiency, which can improve the efficiency in production and ensure its safety and stability. When the car is driving, due to the bumpy extrusion of the ground, each component and structure are under different degrees of impact, which requires the precise strength of the overall structure of the car to be very high. Using the current laser welding technology, its dynamic and static stiffness can be more than 50% higher than other welding processes, reduce the noise and vibration in the process of driving, improve the comfort of riding, but also enhance the safety of the car.

Our company's advantages of laser welding auto body:

➀ The most important advantage of laser welding in automobile manufacturing is the advanced non-contact processing mode. Traditional processing methods such as screw fastening and adhesive connection cannot meet the requirements of precision and firmness in modern automobile manufacturing, and the application of new materials also makes traditional processing methods slightly disadvantageous. Laser welding is contactless, in the process of processing, can not touch the product can achieve precision welding, in the connection of firmness, seamless, precision and cleanliness to achieve the process of leap-forward progress.

➁Laser welding can be used in automobile manufacturing with more stamping parts instead of casting parts, with continuous laser weld instead of scattered spot weld, can reduce the width of the lap and some strengthening parts, reduce the volume of the body structure itself, thereby reducing the weight of the body, to meet the requirements of automobile energy saving and emission reduction.

➂There are hundreds of thousands of parts in the body and chassis of an automobile, and how to connect them together has a direct impact on the rigidity of the vehicle body. Laser welding can almost connect all metal materials of different thicknesses, brands, types and grades together, greatly improving the welding accuracy and assembly accuracy of the body. The rigidity of the body is increased by more than 30%, thus improving the safety of the body. 4. Compared with pure laser welding technology, laser hybrid welding technology can greatly improve the joint ability of sheet metal crevices, so that enterprises can make full use of the stability of arc welding process in laser high-speed welding.

08

Mar