The great thing about modern sheet metal fabrication is the multitude offinishing options available to you to change the appearance of these humbleslabs of meta···

20

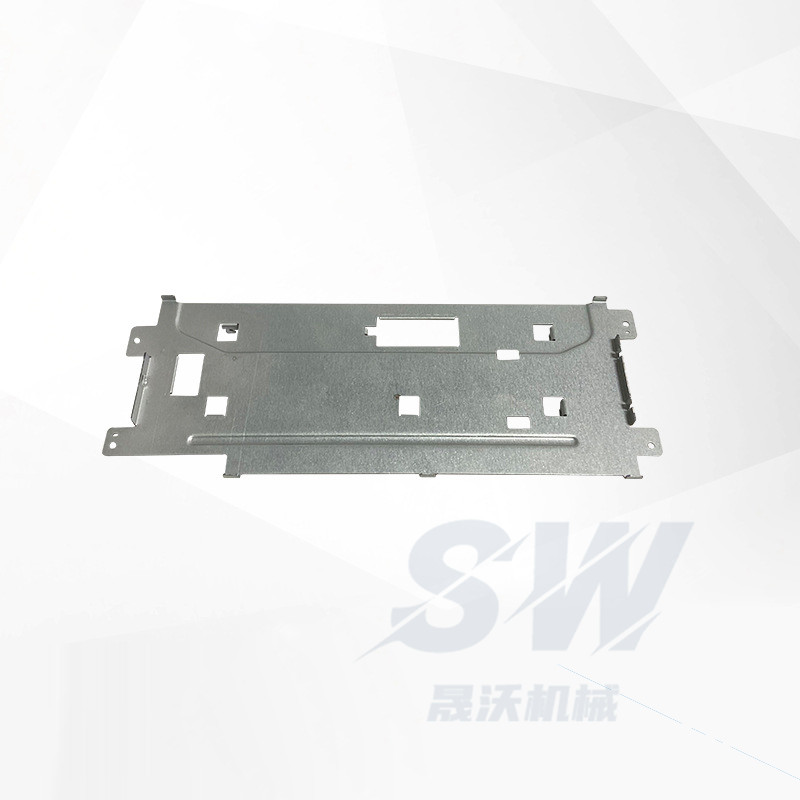

DecShengwo Machinery Products

We provide high quality products according to standard and professional technical service as wellShengwo Machinery Introduction

Providing customers with high quality, one-stop value-added services and products

Shengwo Machinery is a one-stop service company to provide customers with hardware processing (laser cutting, bending, welding), machining, metal stamping and electroplating, spraying a series of surface treatment supporting production. The company has passed ISO14001, ISO9001 certification and SGS ...

Learn moreShengwo Machinery Solutions

Provide targeted technical solutions for different industriesShengwo Machinery News

Technical articles and industry information20

DecThe great thing about modern sheet metal fabrication is the multitude offinishing options available to you to change the appearance of these humbleslabs of meta···

16

DecSheet metal fabrication is the construction of three-dimensional structures by cutting parts from metal sheets and machining them through brake and die presses ···

12

DecIn today's era of rapid technological development, the needs of the medical industry are also growing. As the core part of medical equipment, medical sheet ···

Welcome to browse our website, welcome to contact us for the latest product information and solutionsCONTACT US

contact usShengwo Machinery Products

We provide high quality products according to standard and professional technical service as wellShengwo Machinery Introduction

Providing customers with high quality, one-stop value-added services and products

Shengwo Machinery is a one-stop service company to provide customers with hardware processing (laser cutting, bending, welding), machining, metal stamping and electroplating, spraying a series of surface treatment supporting production. The company has passed ISO14001, ISO9001 certification and SGS ...

Learn moreShengwo Machinery Solutions

Provide targeted technical solutions for different industriesShengwo Machinery News

Technical articles and industry information20

DecThe great thing about modern sheet metal fabrication is the multitude offinishing options available to you to change the appearance of these humbleslabs of meta···

16

DecSheet metal fabrication is the construction of three-dimensional structures by cutting parts from metal sheets and machining them through brake and die presses ···

12

DecIn today's era of rapid technological development, the needs of the medical industry are also growing. As the core part of medical equipment, medical sheet ···

Welcome to browse our website, welcome to contact us for the latest product information and solutionsCONTACT US

contact ustime:2022-03-08 12:36:01hit:256

Laser engraving is the most common application of laser system. According to the mechanism of interaction between laser beam and material, laser processing can be roughly divided into laser thermal processing and photochemical processing. Laser thermal processing refers to the use of laser beam projected onto the surface of the material produced by the thermal effect to complete the processing process, including laser welding, laser engraving and cutting, surface modification, laser laser marking, laser drilling and micro machining; Photochemical reaction processing refers to the processing process in which the laser beam irradiates the object and the photochemical reaction is triggered or controlled by high density laser and high energy photon. Including photochemical deposition, stereo as so on.

Our company's laser processing belongs to non-contact processing, and the energy of high energy laser beam and its moving speed are adjustable, so you can achieve a variety of processing purposes. It can process a variety of metals, non-metals, especially can process high hardness, high brittleness and high melting point materials. Laser processing flexibility is mainly used for cutting, surface treatment, welding, marking and punching. Laser surface treatment includes laser phase change hardening, laser cladding, laser surface alloying and laser surface melting.

Our company laser processing technology mainly has the following unique advantages:

① The use of laser processing, high production efficiency, reliable quality, economic benefits.

② The workpiece in the closed container can be processed through the transparent medium; In harsh environments or places inaccessible to others, laser processing can be carried out by robots.

➂No "tool" wear in laser processing, no "cutting force" on the workpiece.

➃ It can process a variety of metals and non-metals, especially materials with high hardness, high brittleness and high melting point.

⑤ Laser beam is easy to guide, focus to achieve the direction of the transformation, easy to cooperate with the numerical control system, the complex workpiece processing, so it is a very flexible processing method.

➅No contact processing, no direct impact on the workpiece, so no mechanical deformation, and the energy of high energy laser beam and its moving speed are adjustable, so you can achieve a variety of processing purposes.

⑦ laser processing process, laser beam energy density is high, processing speed is fast, and is local processing, no or minimal impact on non-laser irradiation parts, therefore, the heat affected zone is small, the thermal deformation of the workpiece is small, the follow-up processing amount is small.

➇The divergence Angle of the laser beam can 1 milliarc, spot diameter can be as small as micron, action time can be as short as nanosecond and picosecond, at the same time, the continuous output power of high-power laser can reach kilowatt to 10kW, so laser is not only suitable for precision micro-machining, but also suitable for large-scale material processing. Laser beam is easy to control, easy to combine with precision machinery, precision measurement technology and electronic computer, to achieve a high degree of automation and machining accuracy.

Laser processing technology has been widely used in many fields, with the continuous development of laser processing technology, equipment, process research, will have a broader application prospect. Because the heat input workpiece in the process of processing is small, so the heat affected zone and thermal deformation is small; High processing efficiency, easy to realize automation.

08

Mar